Hydraulic drive control device of elevator and manufacturing method thereof

A hoist, hydraulic technology, applied in the direction of hoisting device, lifting frame, transportation and packaging, etc., can solve the problems that the hydraulic drive cannot meet the lifting and lifting operation of the load-bearing object, the hydraulic transmission mechanism does not have two-way drive, and loses use value. Achieve the effect of low power, simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

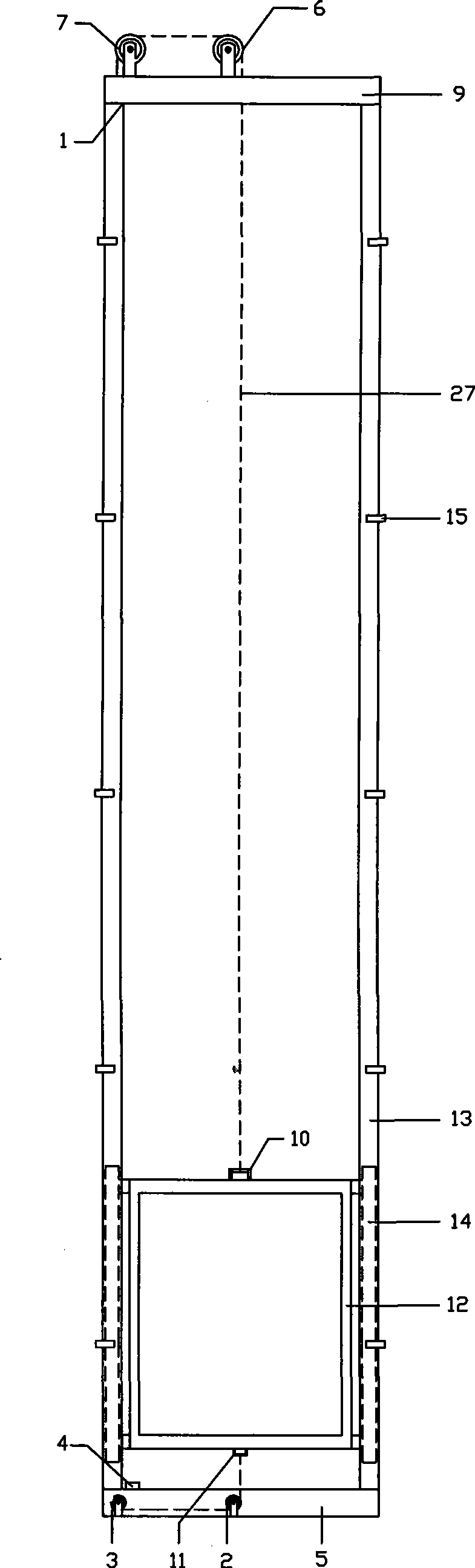

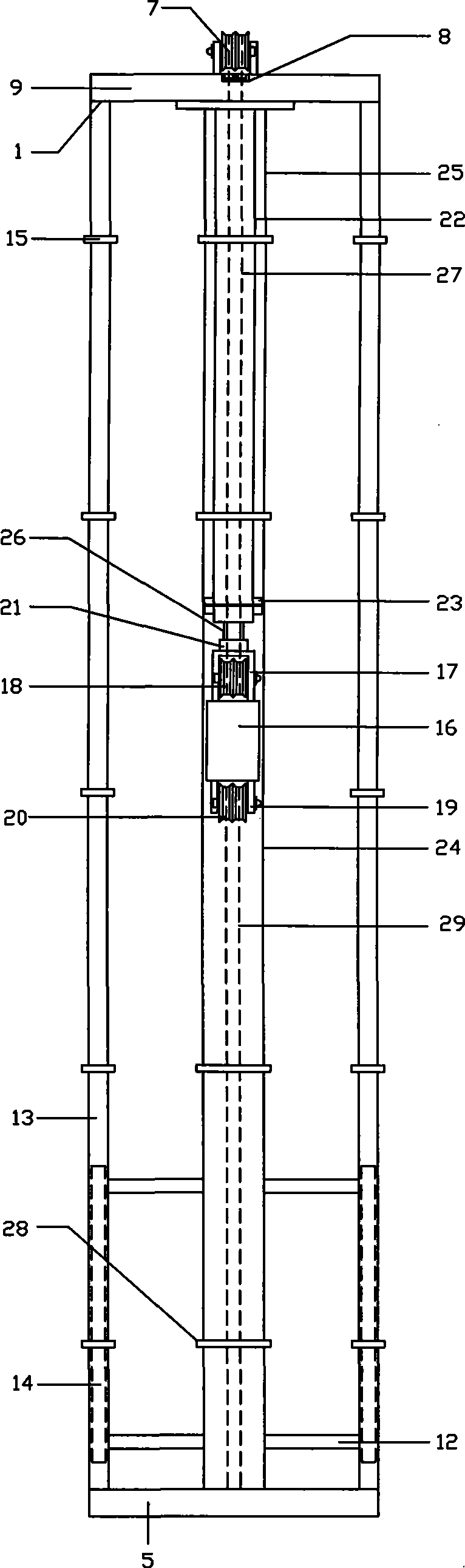

[0016] Example 1: Four-pipe guide hydraulic hoist

[0017] 1. Manufacture of hoist structure 1: Take 160# channel steel to make fixed connection with base positioning pulley 2 with a diameter of 120mm, base change pulley with a diameter of 120mm 3, 1500mm X 1500mm bottom base 5 of base connection device 4; make fixed connection 1500mm X 1500mm top base 9 with 120mm diameter top pulley 6, 120mm diameter change pulley 7, top connection device 8; 1500mm X 1500mm X 2300mm load-bearing structure 12 fixedly connected with lifting device 10 and bottom connection device 11; Four 133mm-diameter open structure guide tubes 13 are fixedly connected to the frame of the bottom base 5, and four 120mm diameter bearing running guide tubes 14 are placed in the open structure guide tubes 13, and are fixedly connected to the load-bearing structure 12 through the connector 15, and the open structure The hoist structure 1 that is fixedly connected to the position corresponding to the top base 8 of ...

Embodiment 2

[0023] Example 2: Three-pipe guide hydraulic hoist

[0024] 1. Manufacture of hoist structure 1: Take 140# channel steel to make fixed connection with base positioning pulley 2 with a diameter of 120mm, base change pulley with a diameter of 120mm 3, base connection device 4 with 1400mm X 1800mm bottom base 5; make fixed connection 1400mm X 1800mm top base 9 with 120mm diameter top pulley 6, 120mm diameter change pulley 7, top connection device 8; 1400mm X 1800mm X 2500mm load-bearing structure 12 fixedly connected with lifting device 10 and bottom connection device 11; Three 152mm-diameter open-structure guide tubes 13 are fixedly connected to the frame of the bottom base 5, and three 140mm-diameter load-bearing running guide tubes 14 are placed in the open-structure guide tubes 13, and are fixedly connected to the load-bearing structure 12 through connectors 15, and the open structure The hoist structure 1 that is fixedly connected to the position corresponding to the top bas...

Embodiment 3

[0030] Embodiment 3: Two-pipe guide hydraulic hoist

[0031] 1. Manufacture of hoist structure 1: Take 140# channel steel to make fixed connection with base positioning pulley 2 with a diameter of 120mm, base change pulley with a diameter of 120mm 3, base connection device 4 with 1400mm X 1200mm bottom base 5; make fixed connection There are 120mm diameter top pulley 6, 120mm diameter reversing pulley 7, 1400mm X 1200mm top base 9 of top connection device 8; make a 1400mm X 1200mm X 2100mm load-bearing structure 12 fixedly connected with lifting device 10, bottom connection device 11; Two 120mm-diameter open-structure guide tubes 13 are fixedly connected to the frame of the bottom base 5, and two 108mm-diameter load-bearing running guide tubes 14 are placed in the open-structure guide tubes 13, and are fixedly connected to the load-bearing structure 12 through the connector 15, and the open structure The hoist structure 1 that is fixedly connected to the position corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com