Drive source of automatic door

A driving source, automatic door technology, applied in electric components, magnetic circuit rotating parts, manufacturing motor generators, etc., can solve the problem of switching labor and other problems, and achieve the effect of reducing the opening and closing load and reducing the opening and closing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, an example of embodiment according to the present invention will be described in detail with reference to the drawings.

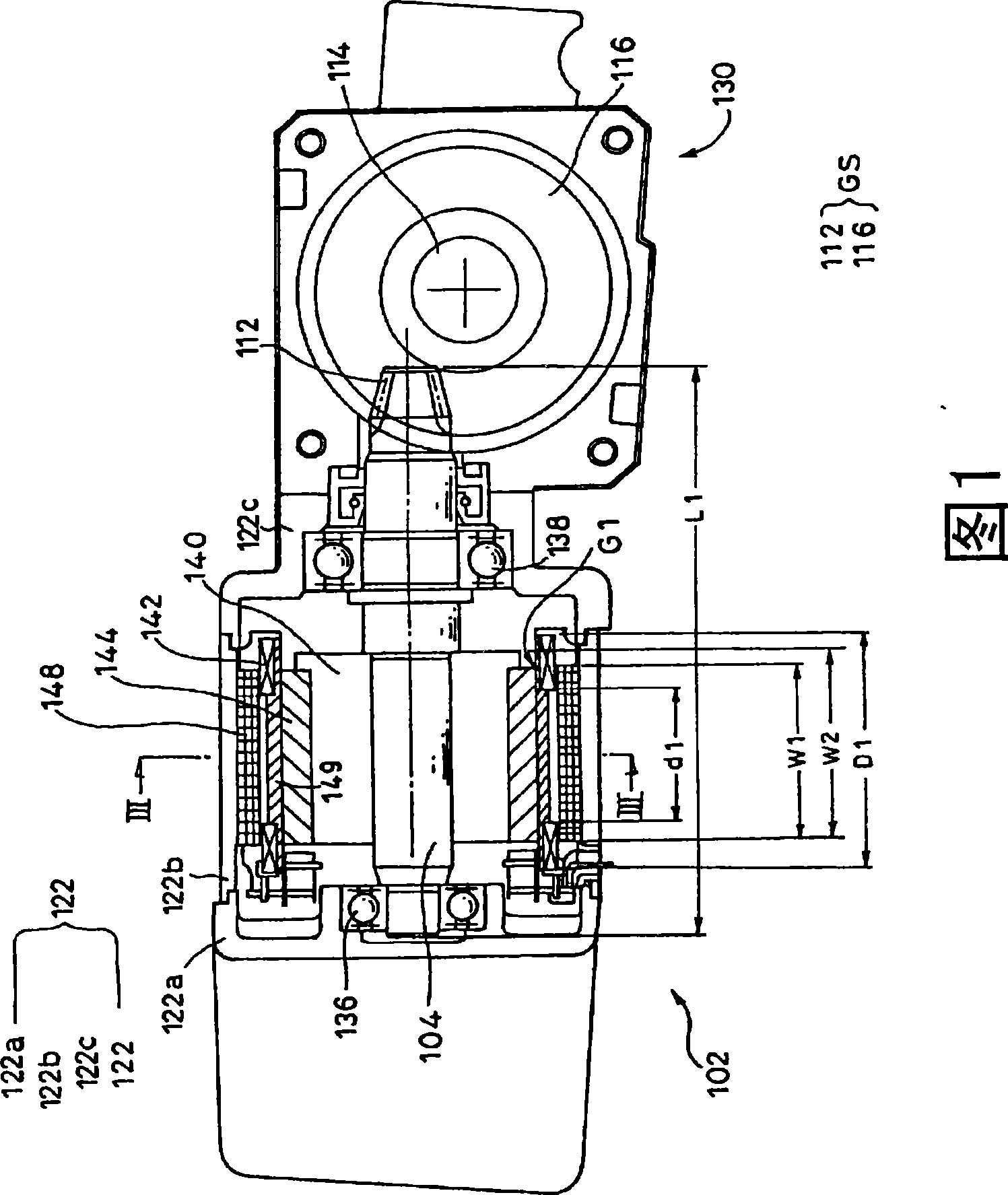

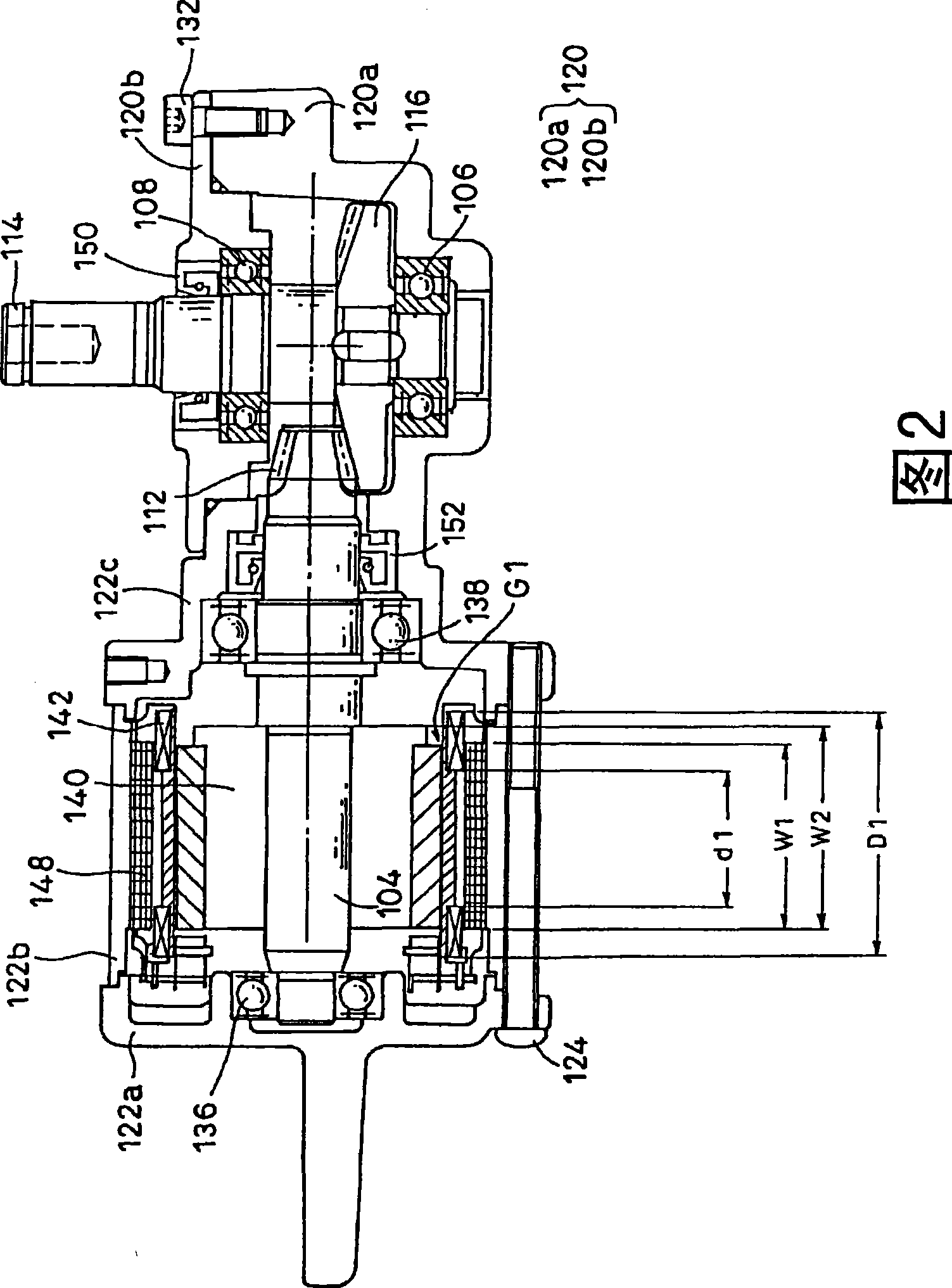

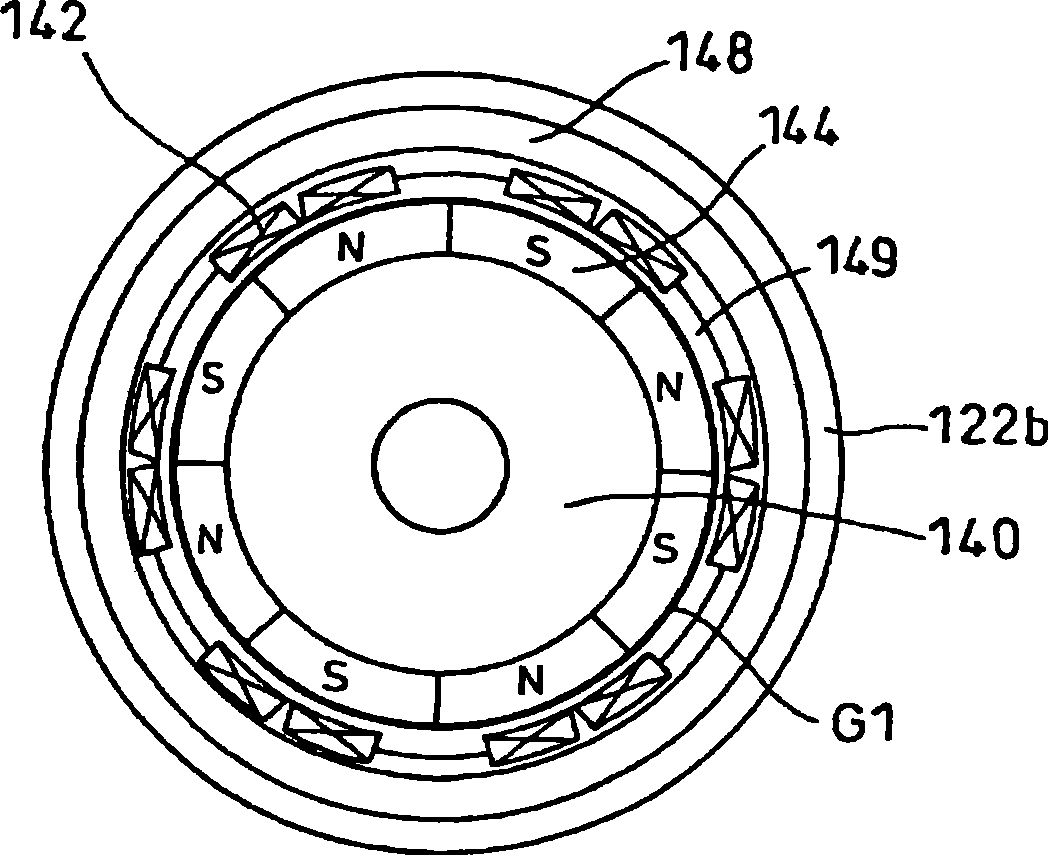

[0027] FIG. 1 is a front sectional view of a drive source 102 for an automatic door as an example of an embodiment of the present invention, and FIG. 2 is a side sectional view thereof, image 3 It is a sectional view along the arrow III-III line in Fig. 1, Figure 4 It is an overall configuration diagram of an automatic door using the driving source 102 .

[0028] The drive source 102 for this automatic door is used together with a speed reducer 130 . The output shaft 114 of the speed reducer 130 drives, for example, a pulley 302 to open and close an automatic door 303 via a door drive belt 301 (refer to Figure 4 ).

[0029] In this embodiment, the speed reducer 130 has a orthogonal gear set GS composed of a hypoid pinion 112 and a hypoid gear 116 .

[0030] In the drive source 102 , a drive source output shaft 104 for outputting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com