Composite stabilizer for preservation of liquid acid protease

An acid protease and composite stabilizer technology, applied in the direction of enzyme stabilization, hydrolase, etc., can solve the problem of difficult to guarantee temperature, and achieve the effect of saving cost, preventing oxidative loss of activity, and not easy to denature and lose activity.

Inactive Publication Date: 2010-08-25

ZHAODONG SUN SHINE ENZYME

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to preserve the enzymatic activity of liquid acid protease, it can only be stored in cold storage, but the temperature is difficult to guarantee during transportation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

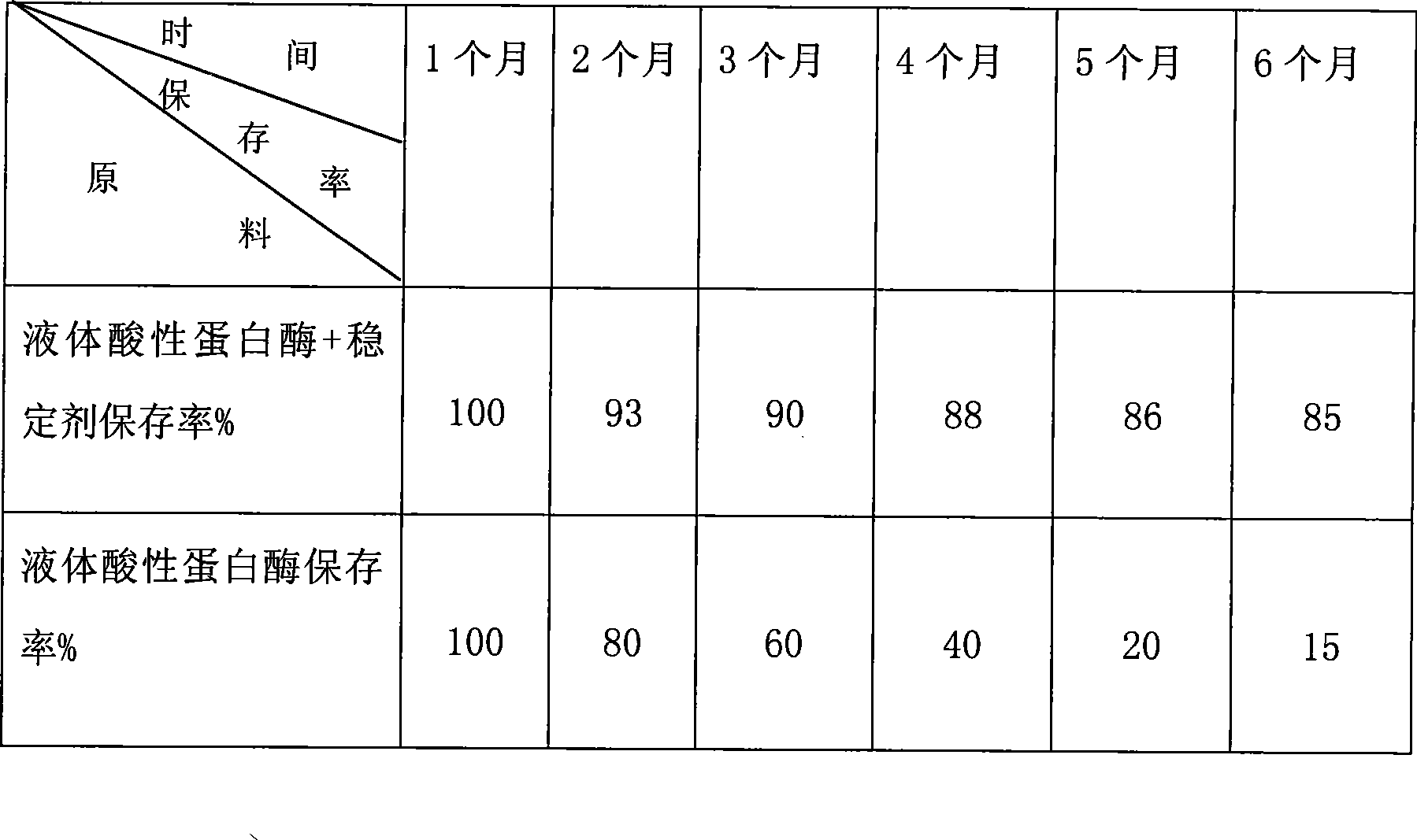

The invention discloses a composite stabilizing agent for preserving a liquid acid protease, which can preserve the activity of the acid protease for a long time under the liquid condition. The composite stabilizing agent is prepared from raw materials including glycerin, glutin, potassium sorbate and sodium hyposulfite by blending and stirring. The weight percentages of the raw materials in the liquid cellulase are as follows: 30 to 50 percent of the glycerin, 1 to 3 percent of the glutin, 0.01 to 0.03 percent of the potassium sorbate and 0.01 to 0.03 percent of the sodium hyposulfite. The composite stabilizing agent uses the glycerin and the glutin so that acid protease molecules keep the stable structures easily in water molecules and are not easy to denaturalize and lose the activity,uses the potassium sorbate to control the colony count so as to meet the requirements on food conditions conveniently, and uses the sodium hyposulfite for preventing enzyme protein from being oxidized to lose the activity. The four raw materials of the composite stabilizing agent is easily available, the food grade is relatively high so that 85 percent of the cellulase activity is kept within sixmonths at room temperature, the cost for building a refrigerated storage for keeping the cellulase activity is saved, and the preservation and transportation of the acid protease are convenient.

Description

technical field The invention relates to a stabilizer for maintaining enzyme activity, in particular to a stabilizer for maintaining liquid acidic protease activity. Background technique The existing domestic acid protease, in order to improve its stability, is mainly preserved by producing solid acid protease, but the solid enzyme colony is not easy to control, and needs to be dissolved when used, and there will be residues. Difficult to meet hygiene standards. When using liquid storage, because protease is a kind of active substance and a kind of protease, it can decompose itself, and the enzyme activity will drop rapidly. At room temperature, the enzyme activity will drop to 10-10 within 6 months. 20%. In order to preserve the enzyme activity of the liquid acid protease, it can only be stored in a cold storage, but it is difficult to guarantee the temperature during transportation. Contents of the invention The object of the present invention is to provide a compoun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12N9/96C12N9/50

Inventor 何勇薛立新李树俊修国立潘金丽曲海军崔明邹春雷任杰

Owner ZHAODONG SUN SHINE ENZYME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com