Prestressed concrete pipe pile

A technology of concrete pipe piles and prestressing, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of increasing the cost and difficulty of pile foundation projects, and achieve the effects of ingenious design, improved bearing capacity, and increased surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

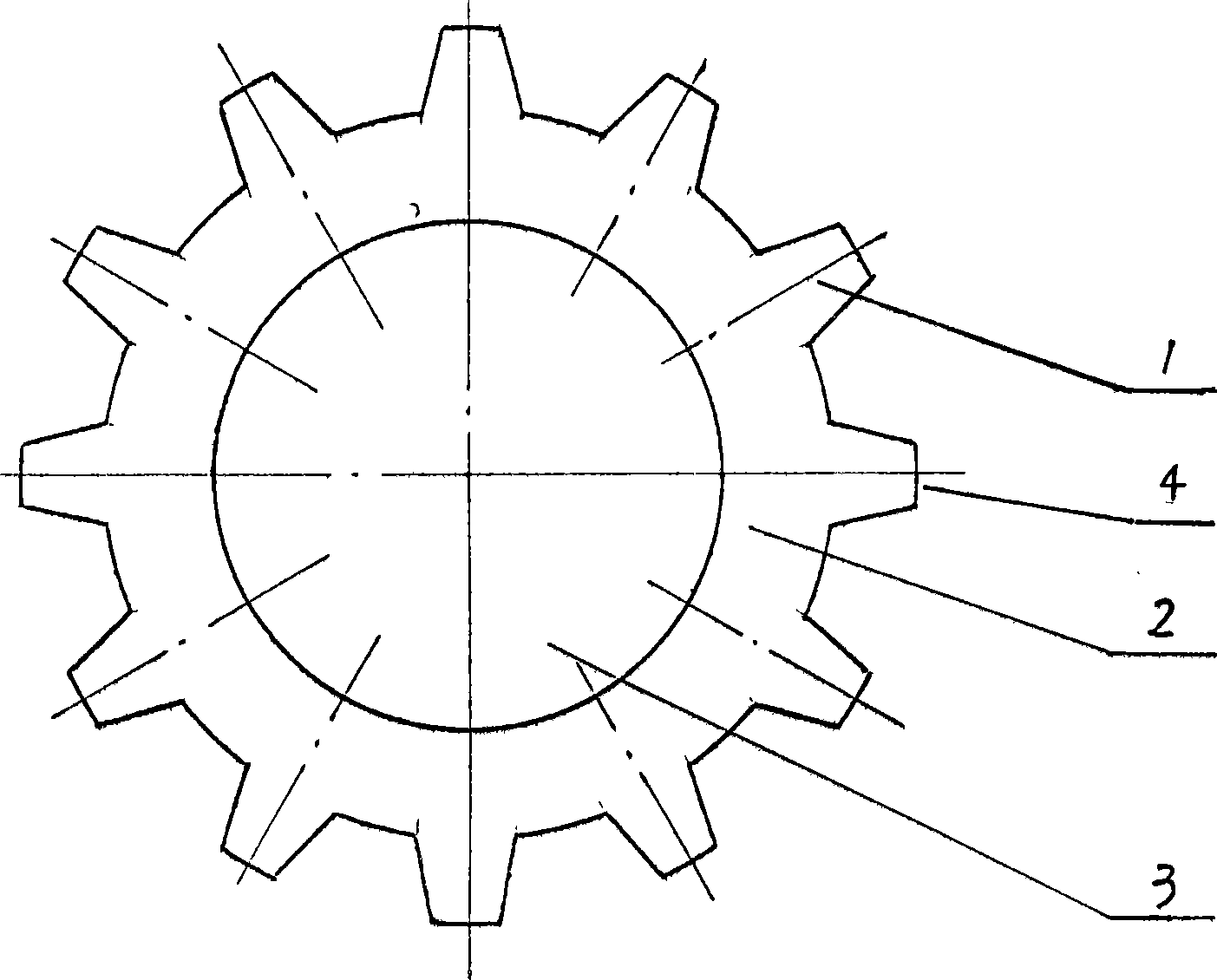

[0014] It can be clearly seen from the accompanying drawings that a prestressed concrete pipe pile is a cylinder with a hollow 3 in the middle, including a pipe wall 2, and a gear shape 1 is designed on the outer peripheral surface of the pipe wall 2, and the gear shape 1 There are twelve convex surfaces 4, and the gear-shaped structure 1 is determined by the coefficient of increasing the surface area of the pipe pile, and its value can be selected between 0-100%, or even higher.

[0015] The present invention also has other implementation forms, such as the design of the concave-convex structure on the outer peripheral surface of the pipe wall, etc., and any design that adopts a friction method on the outer peripheral surface of the pipe wall is regarded as a simple equivalent or replacement, and falls within this scope. within the scope of protection of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com