Device for cleaning wall of dewatering cylinder for continuous centrifugal dewaterer

A centrifugal dehydrator and cleaning device technology, applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve problems such as troublesome operation, loss of energy consumption, and impact on efficiency, and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

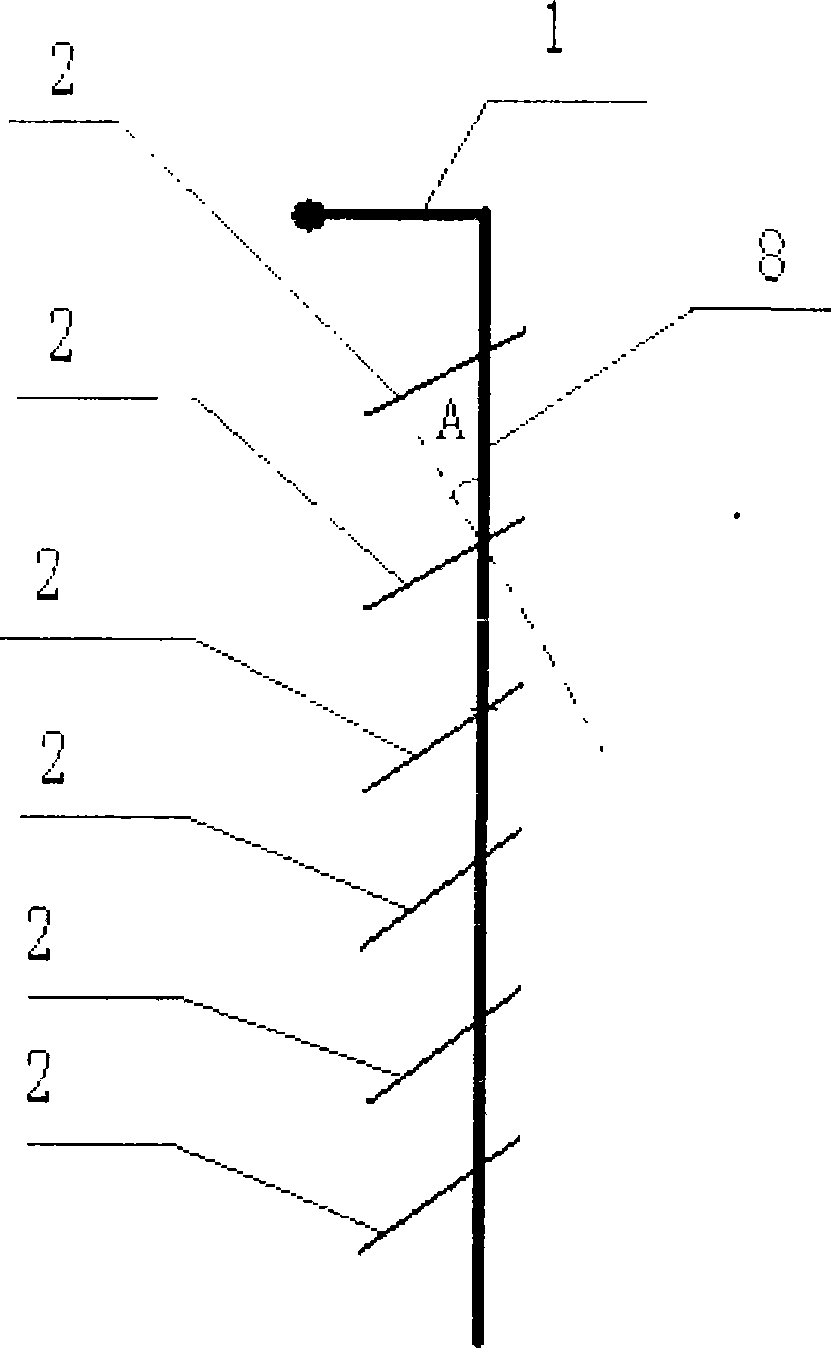

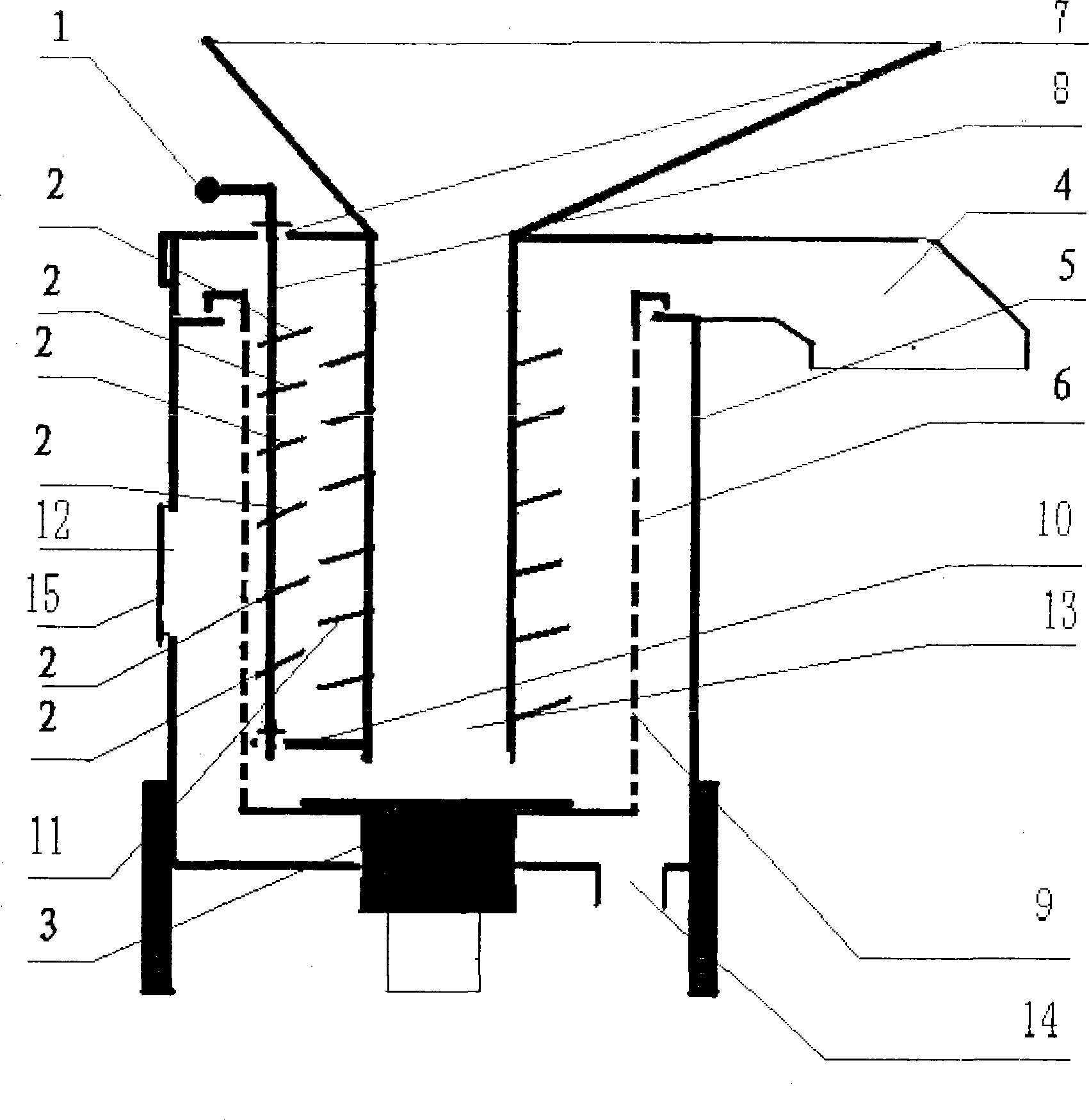

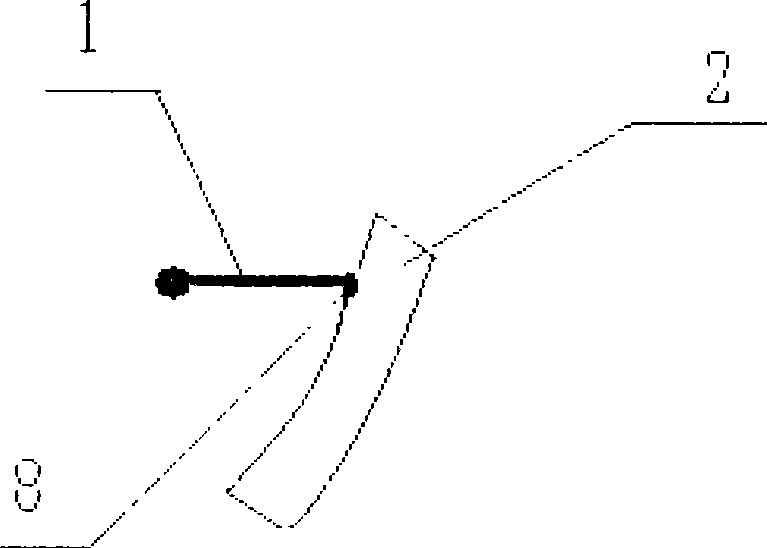

[0011] see Figure 1 and Fig. 2 shows that the present invention is mainly composed of connecting rod 8, blades 2 fixed on the connecting rod 8, and the like. The dehydration cylinder 6 rotates at high speed under the drive of the transmission wheel 3, and the materials adhering to the inner wall of the dehydration cylinder 6 are not in contact with the blades 2. The handle 1 is turned by hand to make the connecting rod 8 rotate at a certain angle, so that the blades 2 and the dehydration cylinder 6 The distance between the inner walls shrinks or the material adheres to the inner wall of the dehydration cylinder, and the force generated by the difference in speed between the inner wall of the rotating dehydration cylinder 6 and the blade 2 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com