Method for precision measurement of points on space surface and space surface by barycenter coordinate

A center-of-gravity coordinates and precision measurement technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical counters/curvature measurement, etc., can solve problems such as difficult calculations, measurement errors, and wrong measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

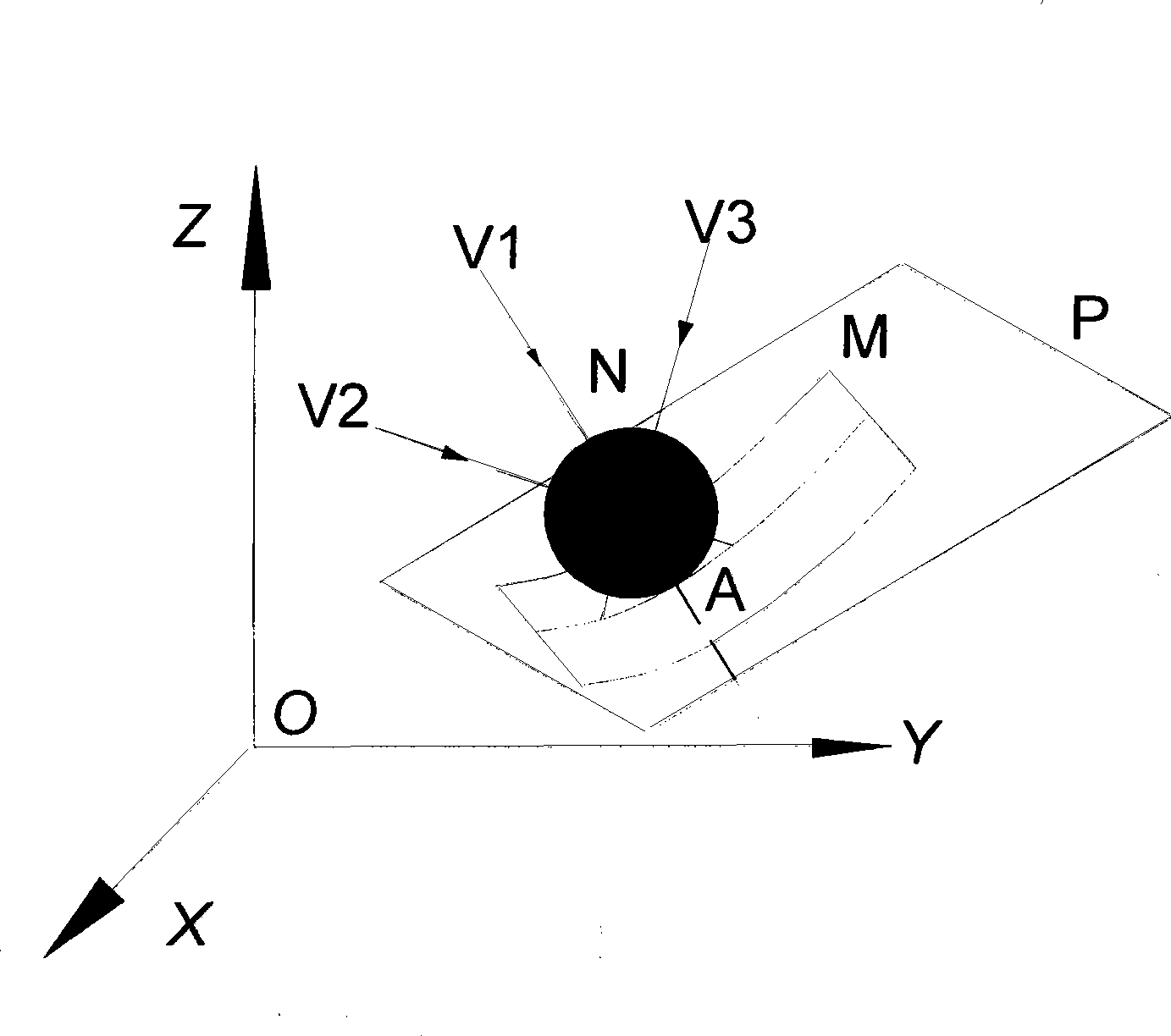

[0060] Embodiment 1: Measurement and program design method of any feature point on any space surface

[0061] The precise measurement of points on any space surface cannot be completed in manual mode, and a program must be designed to automatically measure in NC mode.

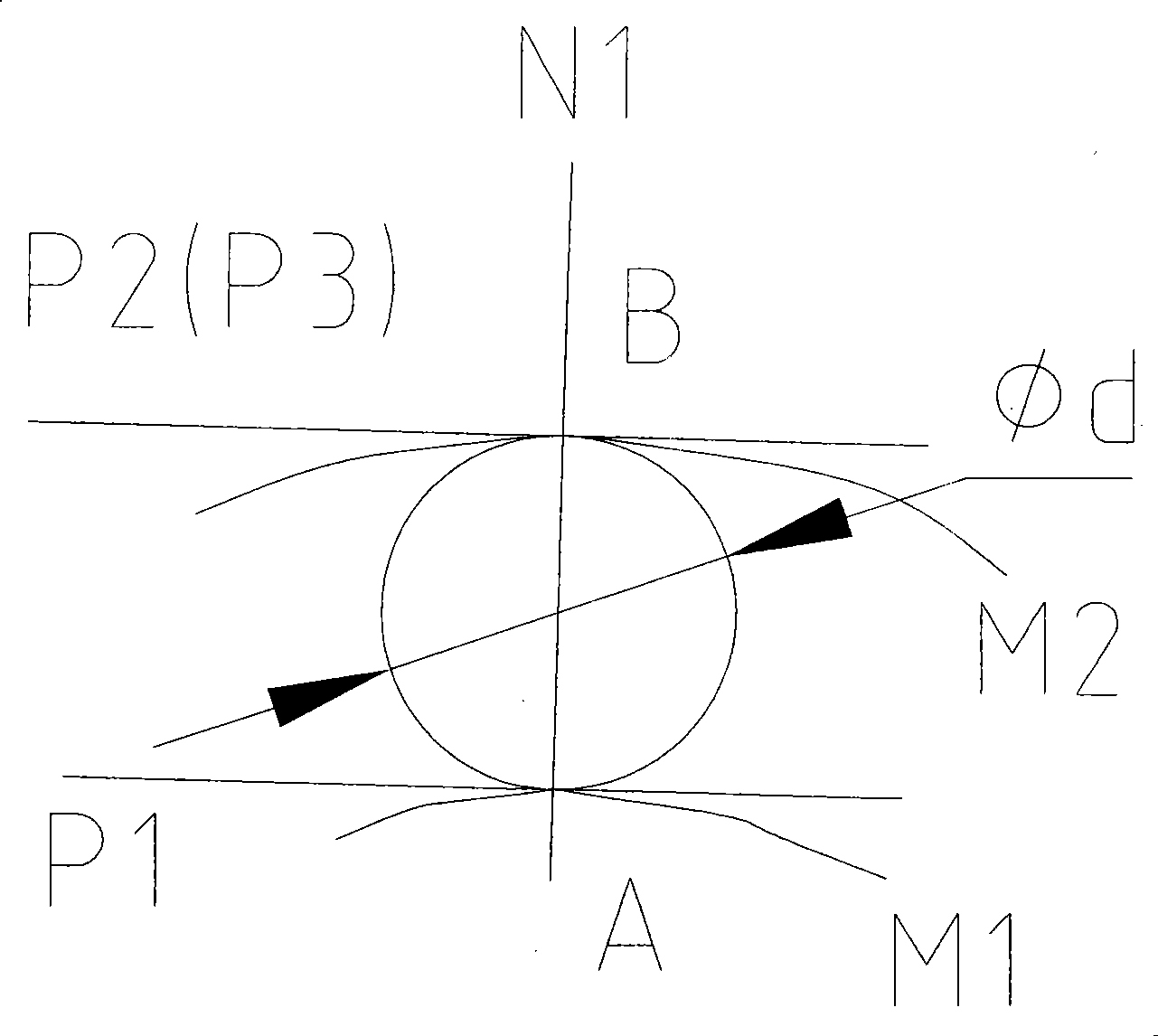

[0062] see Figure 4 and Figure 5 , let the projection coordinates of any feature point on the space surface in XOY be: (x0, y0), let it be the center of gravity coordinate G, then the apex coordinate of the regular triangle is M1 j+1 (x0-2d / 3, y0), M3 j+1 (x0+d / 3, y0-k) and M3 j+3 (x0+d / 3, y0+k). In this way, the conditional points on the space surface that are projected as equilateral triangles have been determined, and the z coordinates of the three points are undetermined. Turn off the radius compensation of the stylus, measure the three points, obtain their three-dimensional coordinates, and calculate the miniature of the three points. The coordinates of the center of gravity of the triangle and its ...

Embodiment 2

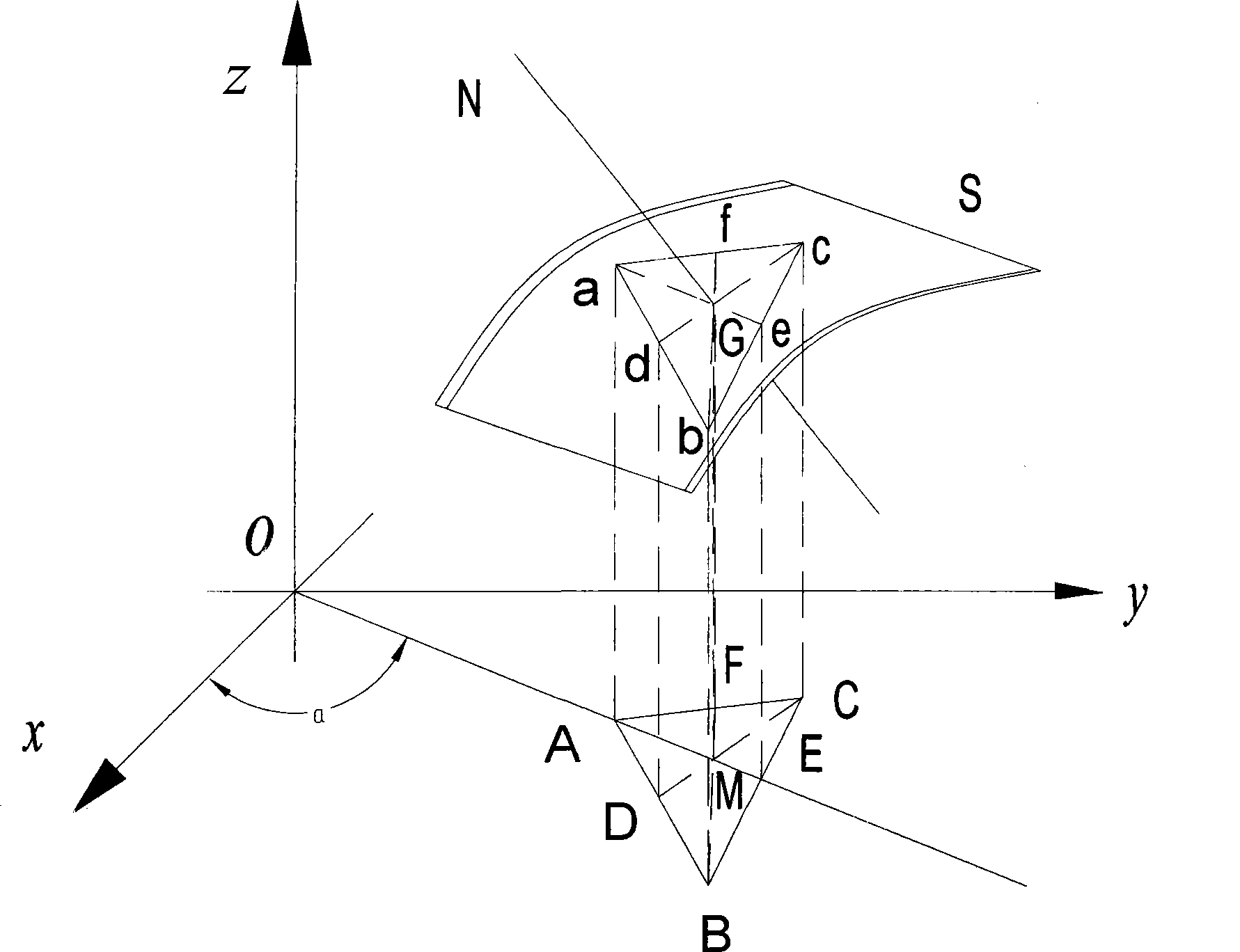

[0075] Embodiment 2: measurement of space surface

[0076] Several measurement points are successively established on the projection surface of the space surface, and the precise coordinate values of each measurement point are obtained by using the above method respectively, so as to obtain the entire contour coordinate value on the space surface.

[0077] Figure 7 see as image 3 projection, such as Figure 7 As described above, in establishing the coordinate system at the center of rotation of the space surface, in the projected XOY coordinates, the space rotation surface is measured with equal divisions. To ensure that M3 j+1 , M3 j+3 and M1 j+2 An equilateral triangle is formed in projected XOY coordinates. From Figure 7 Geometric analysis: the height of the equilateral triangle is d, and the polar angle variation of each vertex is the same θ, M1 j+2 , positive ΔABC center and M3 j+1 The polar radii of the points are R1, R2, R3, respectively. Then get the mat...

Embodiment 3

[0092] Embodiment 3: space surface test on the standard sphere:

[0093] The contour on the standard sphere can be regarded as a space curved surface. Since the standard sphere has a high-precision contour surface, it is the reference calibration ball of the measuring machine. If the above-mentioned theoretically designed program is used to test the space curved surface on the standard sphere, then the test result It can also be used as a scientific basis for evaluating measurement procedures and methods.

[0094] The parameters of the standard ball are: the diameter deviation is 0.00015mm, and the average diameter is about 15.875152mm. Such as Figure 8 , establish a measurement coordinate system on the sphere, and its center is set at the center of the sphere, and test the space surface of the upper hemisphere:

[0095] The first step: according to Figure 4 To construct the geometric characteristics of a regular triangle, first determine the position of each vertex of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com