Full automatic mineral sampling and sample-preparing system in set and mineral sampling and sample-preparing method thereof

A sample preparation system and fully automatic technology, applied in sampling devices, preparation of test samples, etc., can solve the problems of low accuracy of test data, cumbersome operation procedures, low degree of automation, etc., to reduce human factors and eliminate human factors. The effect of interference and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

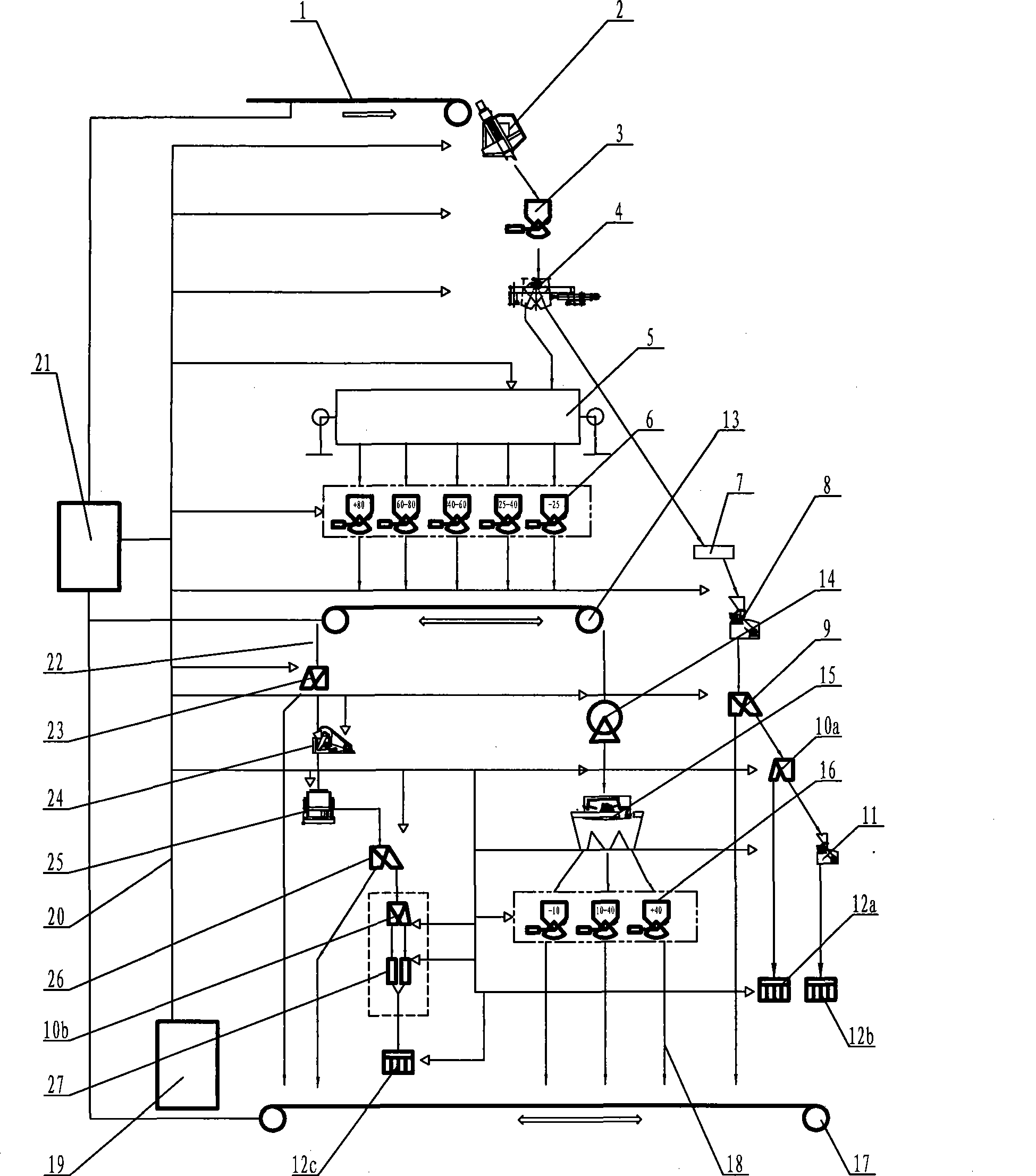

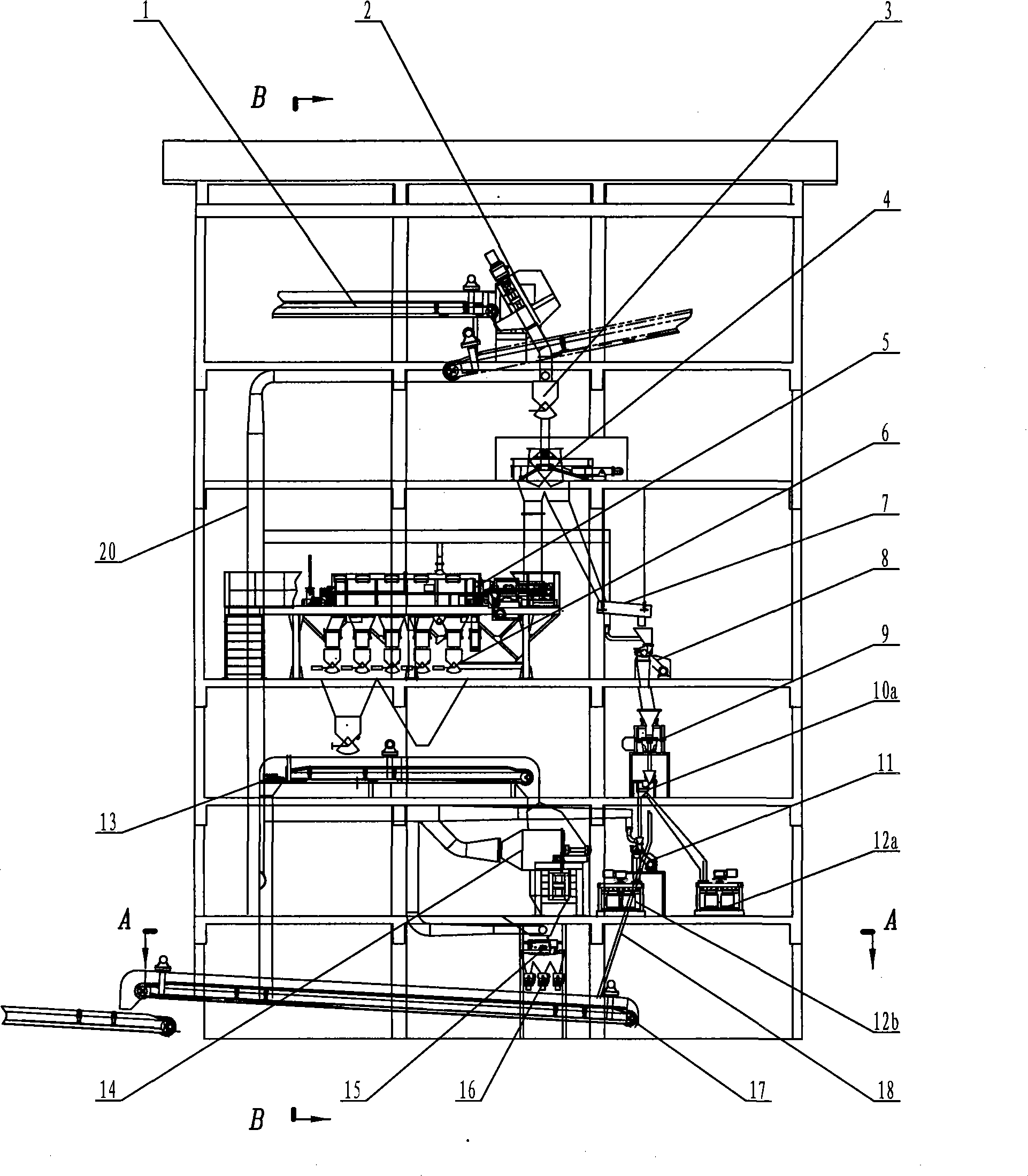

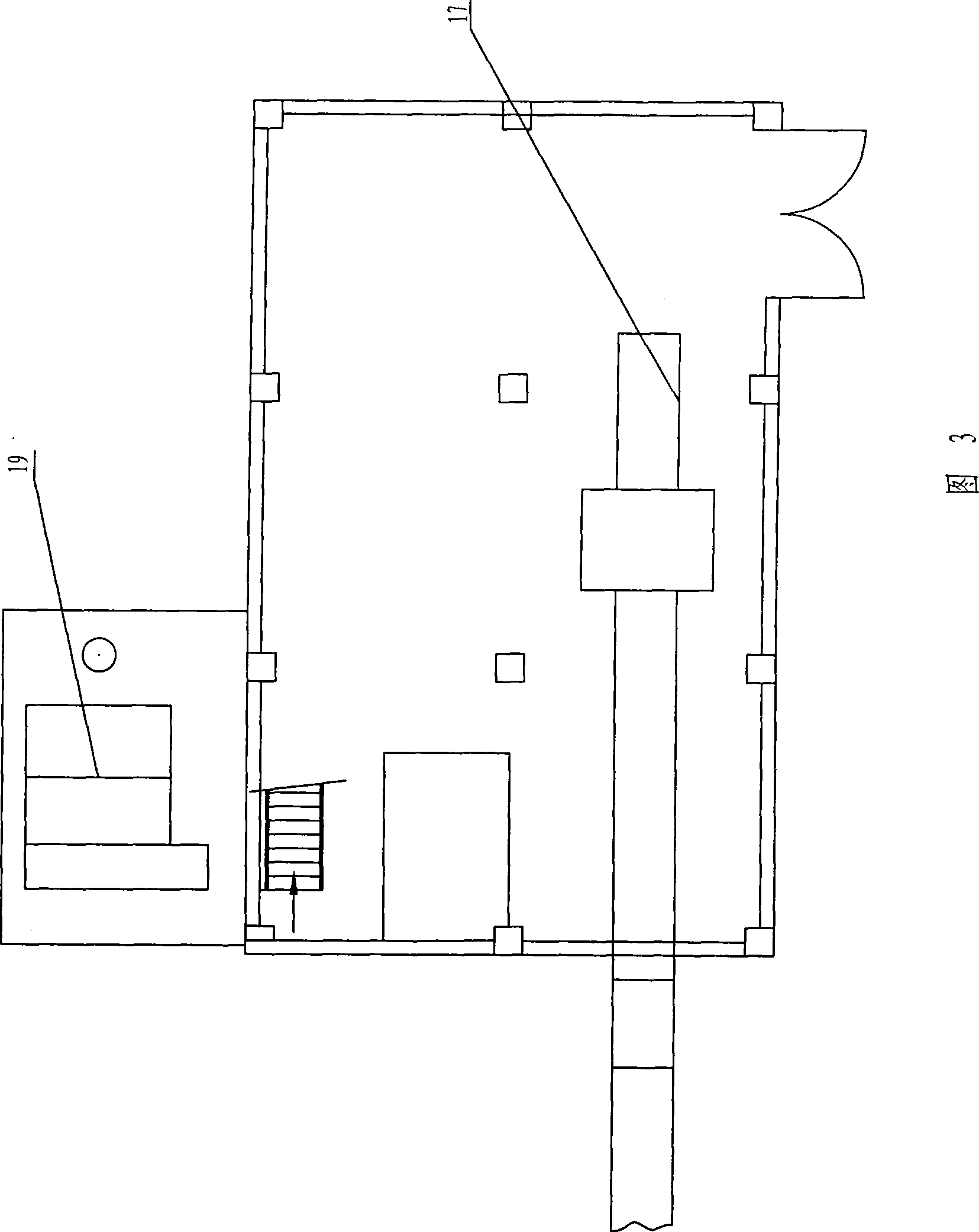

[0014] Embodiment 1: as Figure 1 to Figure 4 As shown, the full-automatic mineral sampling and preparation system includes a material conveying device 1, a head sampling machine 2, a weighing storage hopper 3, a swing chute 4, a drum type cylinder screening machine 5, and a weighing and feeding scale group 6 , vibrating feeder 7, large crusher 8, adjustable shrinking machine 9, two-pointer 10a, small crusher 11, sample collector 12a, 12b, reversible belt feeder 13, drum 14, three-stage sieve 15, Weighing hopper group 16, waste belt conveyor 17, chute 18, dust collector 19, dust removal pipeline 20 and PLC controller 21, head sampling machine 2, weighing storage sample hopper 3, swing chute 4 are connected through chute 18 , the swing chute 4 is respectively connected with the drum type cylinder screening machine 5 and the vibrating feeder 7 through the chute 18, the vibrating feeder 7 is connected with the large crusher 8 through the chute 18, and the drum type cylinder scree...

Embodiment 2

[0015] Embodiment 2: as Figure 1 to Figure 4 As shown, the full-automatic mineral sample preparation system also includes a heat strength test sample preparation system 22, and the heat strength test sample preparation system 22 includes a rotary chute 23, a jaw crusher 24, a secondary sieve 25, and a shrink Submachine 26, splitter 10b, type I drum 27 and sample collector 12c, the other end of reversible belt feeder 13 is connected with rotary chute 23 through chute 18, rotary chute 23, jaw crusher 24, secondary sieve 25 , shrinkage divider 26, splitter 10b, type I drum 27, sample collector 12c are all connected by chute 18, rotary chute 23, jaw crusher 24, secondary sieve 25, shrink splitter 26, divider 10b, Type I rotating drum 27 and sample collector 12c are all connected to dust collector 19 through dust removal pipeline 20, rotating chute 23, jaw crusher 24, secondary sieve 25, shrinking machine 26, splitter 10b, Type I rotating drum 27, The sample collectors 12c are al...

Embodiment 3

[0016] Embodiment 3: as Figure 1 to Figure 4 As shown, a kind of method that adopts the complete set of full-automatic mineral sampling preparation system described in embodiment 1 to carry out mineral sampling preparation is: a. Sampling: head sampling machine 2 presses 6r / min rotation speed at material conveying device 1 head Part sampling and slipping into weighing and storing sample hopper 3 by chute 18, weighing and storing sample hopper 3 obtains required ore sample by the weight of setting, b. sample delivery: the ore sample of weighing and storing sample hopper 3 is passed through chute The pipe 18 slips into the swing chute 4, and the ore sample is sent into the drum type cylinder screening machine 5 through the chute 18 as required or sent into the large crusher 8 through the vibrating feeder 7, c. sample preparation: if the ore sample is sent into The drum-type drum screening machine 5 screens the ore samples into 5 specifications of different sizes through the 5-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com