Oil bath type lubricating device for motor with large axial load

A lubricating device, high-load technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of reducing the service life of the thrust bearing, poor fluidity, and overheating damage of the thrust bearing, achieving a large heat dissipation area, timely observation and replacement. , to ensure the effect of lubrication and heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

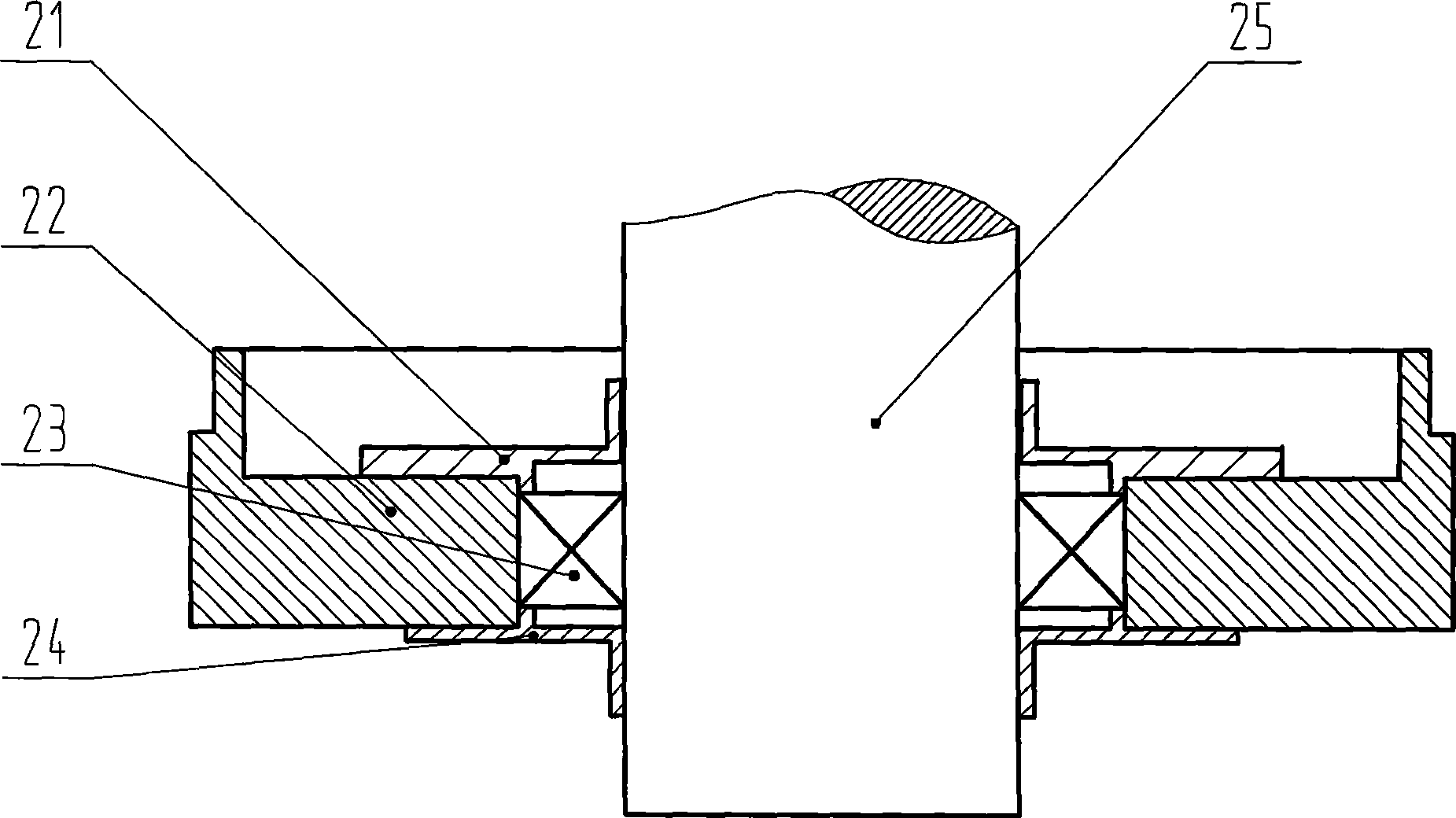

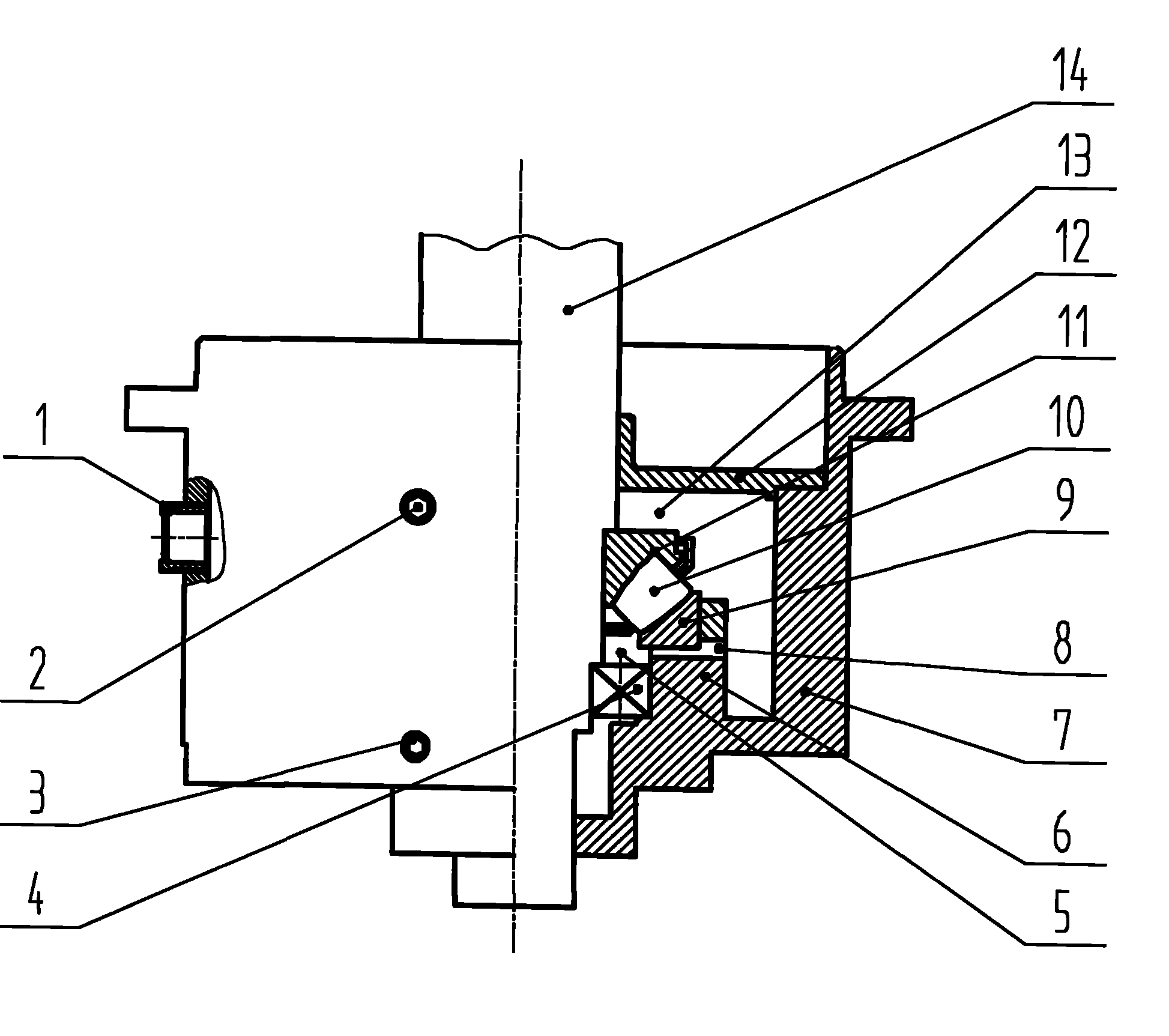

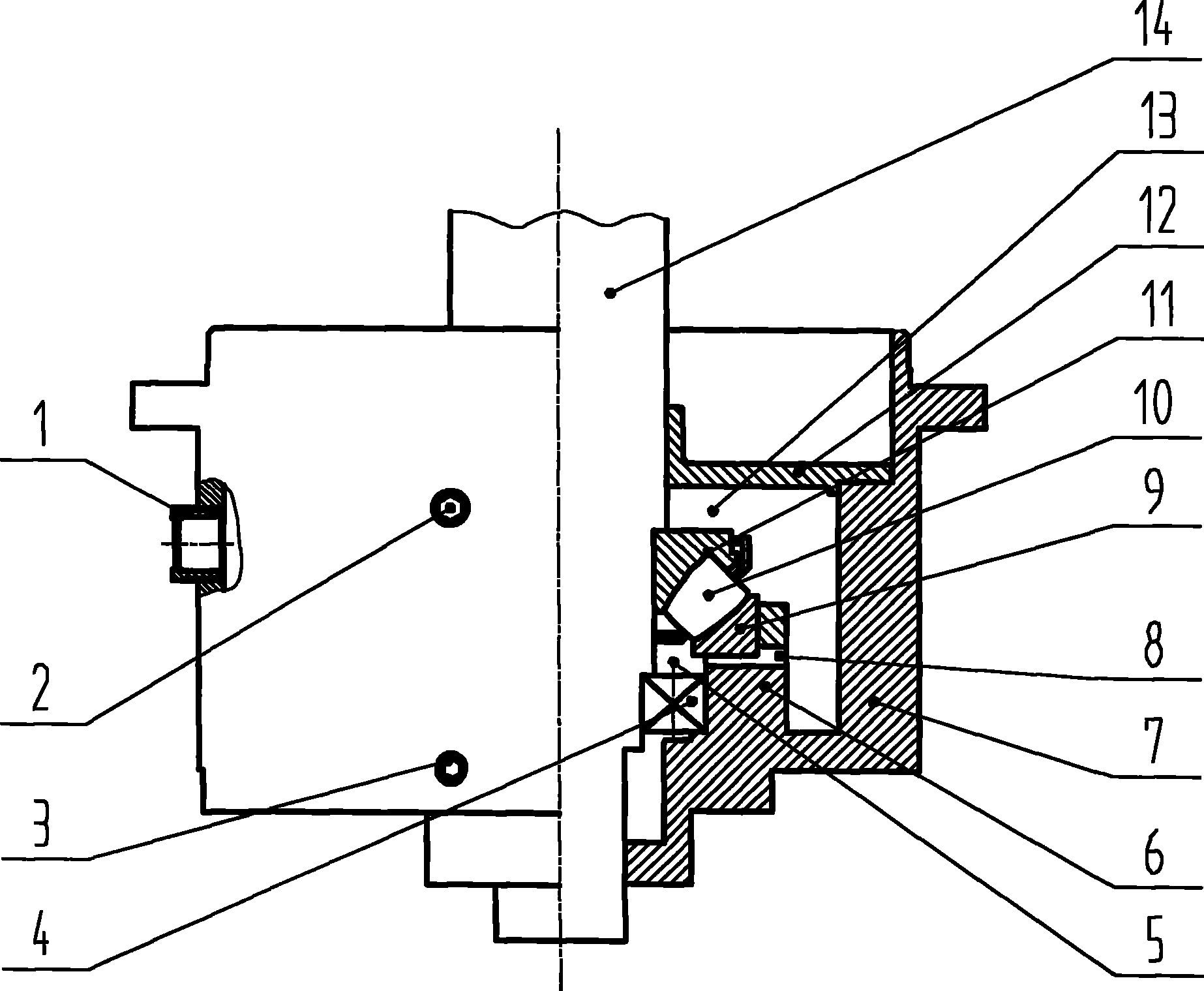

[0013] exist figure 2 Among them, the oil bath lubrication device for motors with large axial loads, the shaft ring 11 of the high-performance spherical roller thrust bearing 10 is installed on the load-bearing end of the motor shaft 14, and the seat ring 9 of the high-performance spherical roller thrust bearing 10 is installed on the large In the bearing seat 6 in the end cover 7 with aspect ratio, the support bearing 4 is embedded in the end cover 7 with large aspect ratio, and is installed on the shaft end of the motor shaft 14 below the high-performance spherical roller thrust bearing 10, and the support bearing 4 The bearing chamber 5 is formed between the spherical roller thrust bearing 10, and the bearing inner cover 12 is installed on the upper part of the large aspect ratio end cover 7 above the high performance spherical roller thrust bearing 10, and the bearing inner cover 12 is connected with the large aspect ratio end The cover 7 forms a large-volume oil chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com