Process for producing hot-dip galvanized steel sheet with zinc phosphate coat

A technology of hot dip galvanizing and manufacturing method, applied in the direction of metal material coating process, etc., can solve problems such as insufficient performance, and achieve the effects of improving stability, improving productivity and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] As Example 1, for a plate thickness of 0.8 mm, a cut plate of 200 mm × 250 mm, that is, an extremely low carbon steel plate GI steel plate (plating adhesion amount 90 g / m 2 , film Al concentration: 0.4% by mass, Fe concentration: 1.5% by mass) and GA steel plate (plating adhesion: 60g / m 2 , film Al concentration: 0.30% by mass, and Fe concentration: 9.5% by mass) were evaluated for operability and lubricity for these two types of hot-dip galvanized steel sheets. In this example, the evaluation was performed by the presence or absence of the above-mentioned pre-drying step when the components of the surface conditioner and the components of the treatment agent were changed. Table 1 and Table 2 show the components of the surface treatment agent and the components of the treatment agent, respectively.

[0133] (Table 1) Components contained in the surface conditioner

[0134]

[0135] (Table 2) Components contained in the treatment agent

[0136] no

[Zn]...

Embodiment 2

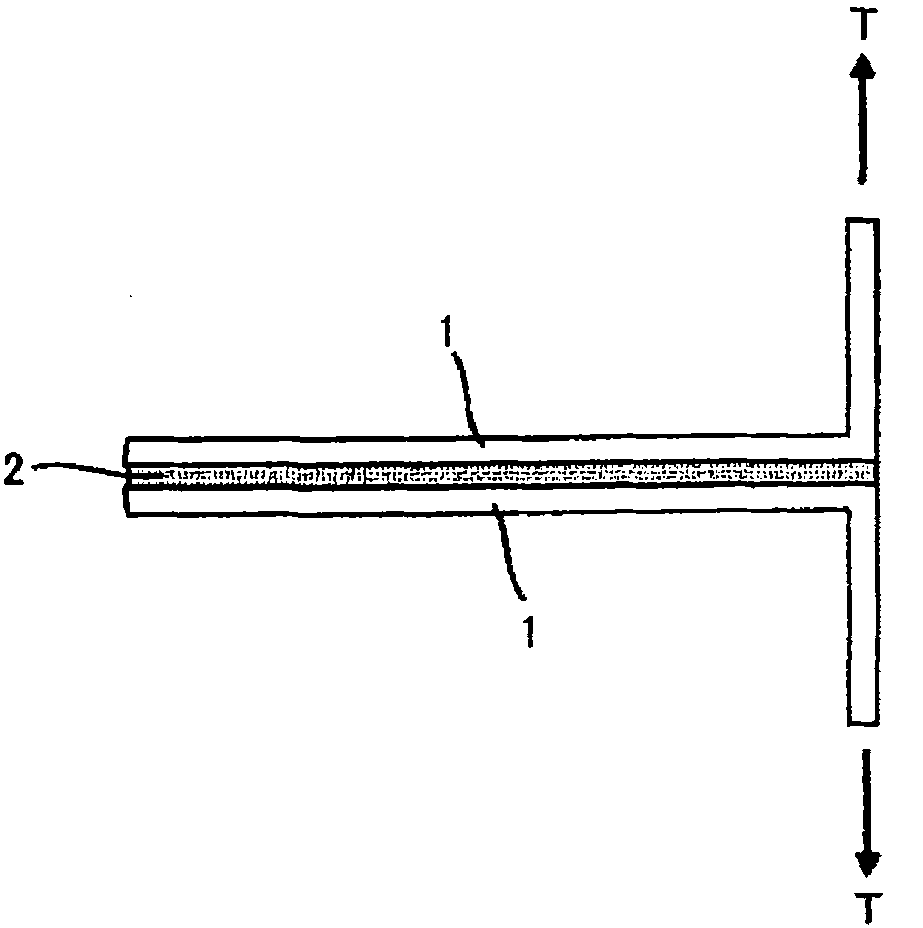

[0202] Embodiment 2 is by continuous hot-dip galvanizing class steel plate production line, to the GA steel plate (extremely low carbon steel plate, plating adhesion 45g / m2) of plate thickness 0.8mm 2 , film Al concentration: 0.25% by mass, Fe concentration: 9.0% by mass) was smoothed (rolling rate 1.0%), and in the surface conditioner supply process, No. 1, 4, and 6 surface conditioners shown in Table 1 were supplied , The treatment agent process uses the treatment agents a, d, e and i in Table 2 for zinc phosphate film treatment.

[0203] Surface conditioner supply process

[0204] Supply Method: Spray or Roller

[0205] Drying equipment: dryer

[0206] Adhesion amount: 3mg / m in P conversion 2

[0207] pre-drying process

[0208] Drying temperature: the highest temperature of the steel plate is 70°C

[0209] Drying time: 5 seconds

[0210] Treatment agent supply process:

[0211] Supply method: Roller coating (invasion agent temperature 50°C)

[0212] post-drying pr...

Embodiment 3

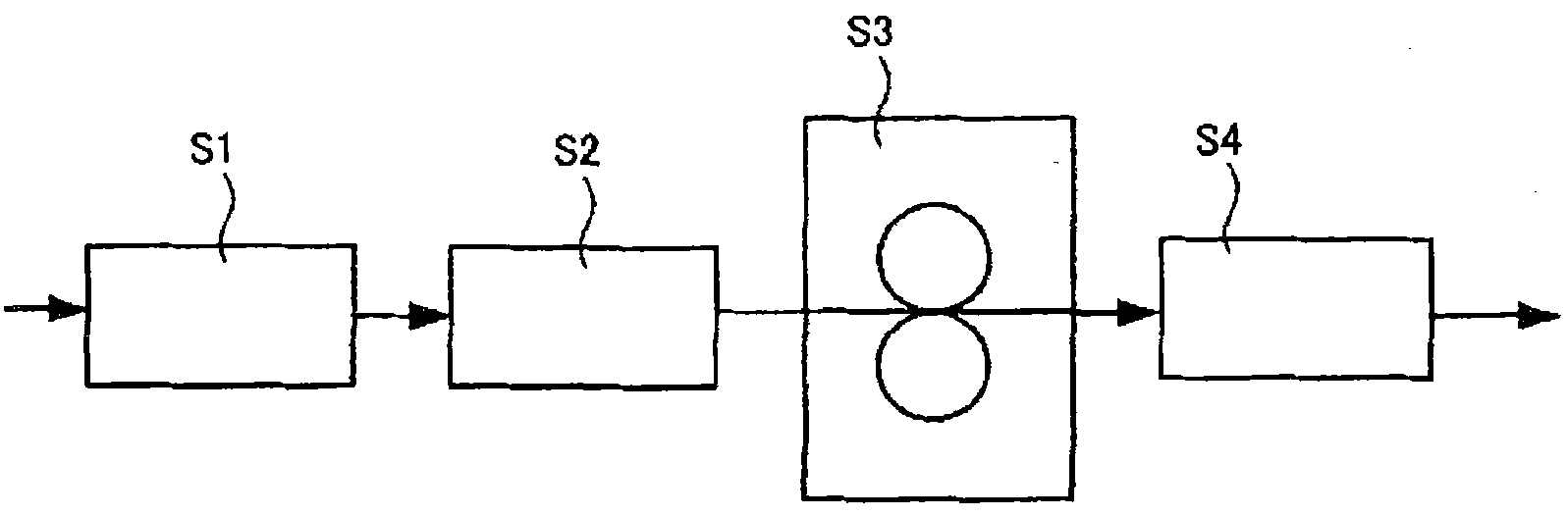

[0270] Utilizing FCL4480 (20g / L, 45°C) manufactured by Nippon Parka Raiding Co., Ltd., spray degreasing for 30 seconds on both sides of an ultra-low carbon steel plate with a plate thickness of 0.8mm, and then perform degreasing. Washed and dried and made into test panels. Thereafter, the surface conditioner supply (S1) to the post-drying process (S4) are implemented to manufacture a galvanized steel sheet having a zinc phosphate film. Furthermore, various evaluations were performed on the galvanized steel sheet having the zinc phosphate film. Hereinafter, conditions, evaluation items, and results will be described. In addition, as a comparison, a steel plate subjected to only the surface conditioner supply process (S1) and a pre-drying process (S2), and a steel plate subjected to only a treatment agent supply process (S3) and a post-drying process (S4) were produced. In addition, as a current example, an electroplating layer with a composition of 80% by mass Zn was formed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com