Gun rivet

A technology of rivets and rivets, applied in the direction of rivets, screws, threaded fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

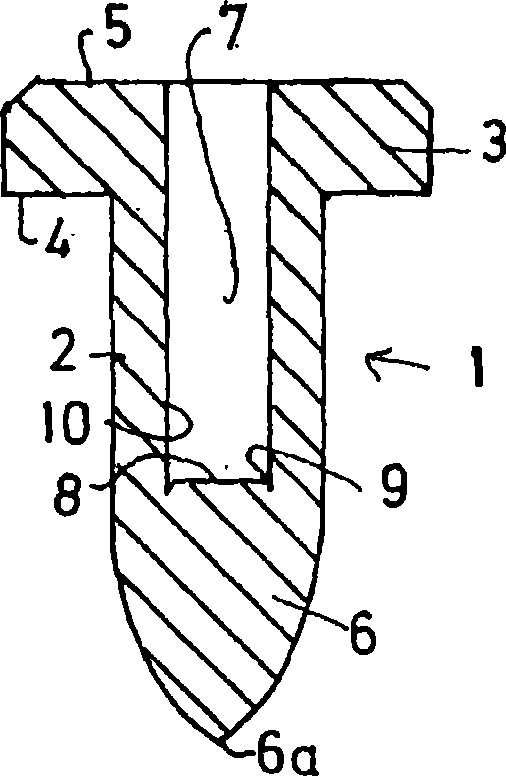

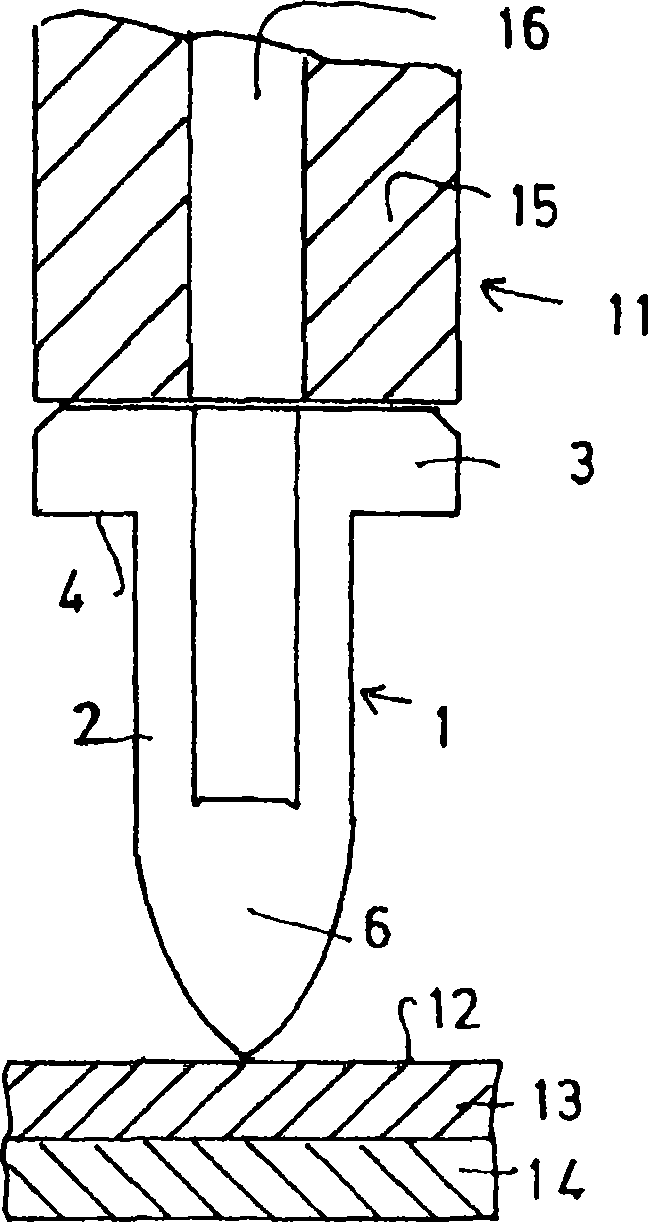

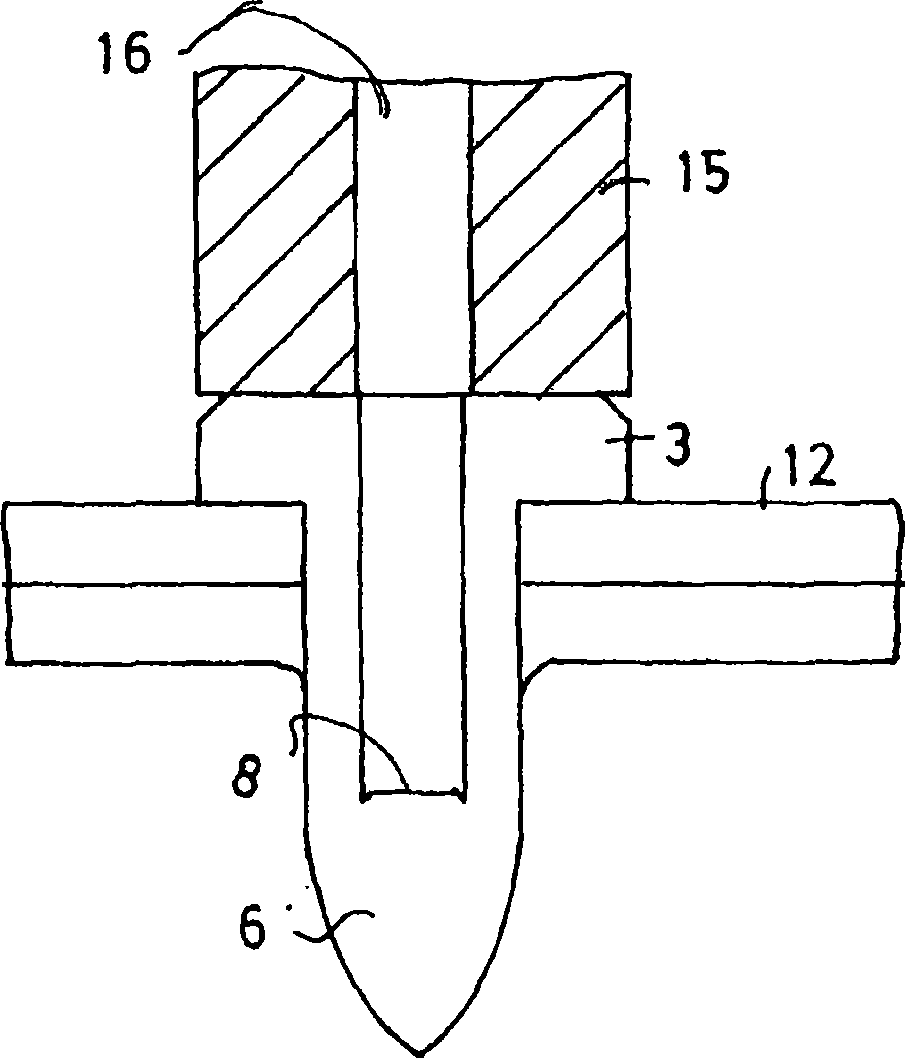

[0039] figure 1 A longitudinal section through a shooting rivet according to the invention is shown. The shooting rivet comprises a rivet body 1 which is designed in its central region as a rivet sleeve 2 . At one of the ends, a flange 3 is formed on the rivet body 1 , which flange 3 has a flat limiting surface on its underside 4 . The underside is the side facing in the direction of the rivet tip 6 . An active surface for accommodating a tool is provided on an upper side 5 , which is also designed to be flat or approximately flat, opposite the flat bottom side 4 .

[0040]At the end facing away from the flange 3, the rivet point 6 is formed, in which the cross-section of the rivet body decreases continuously up to a real point 6a. A recess 7 is formed in the rivet body 1 in the shape of a borehole, ie with a cylindrical cross-sectional shape. The recess 7 ends in a bottom 8 which is separated from the wall 10 of the recess 7 by a circumferential cutout 9 .

[0041] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com