Pilot-controlled pressure limiting valve

A pressure-limiting valve and pilot-operated technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problem of increasing the amount of control fluid, and achieve the effects of eliminating blockage, simplifying production, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

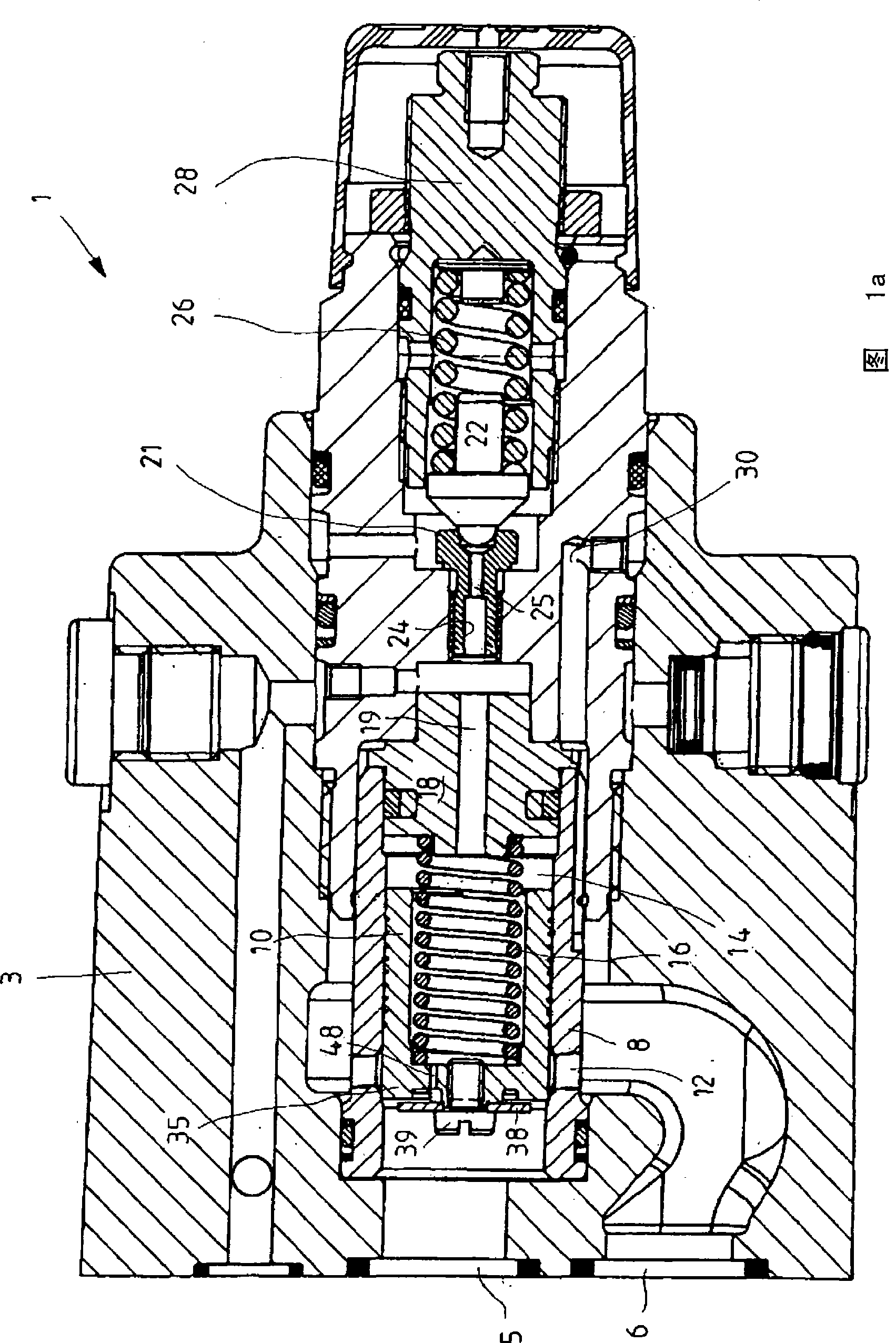

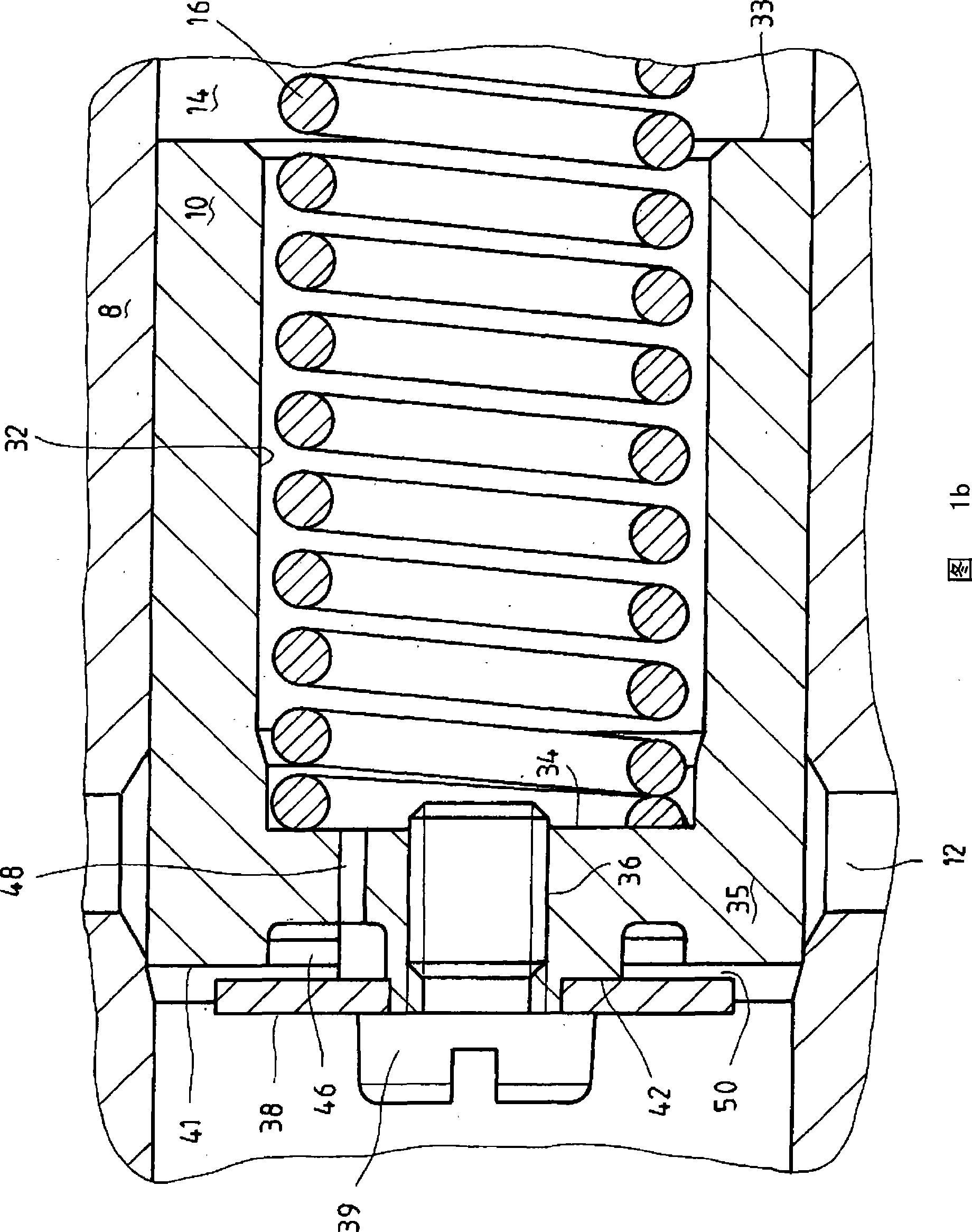

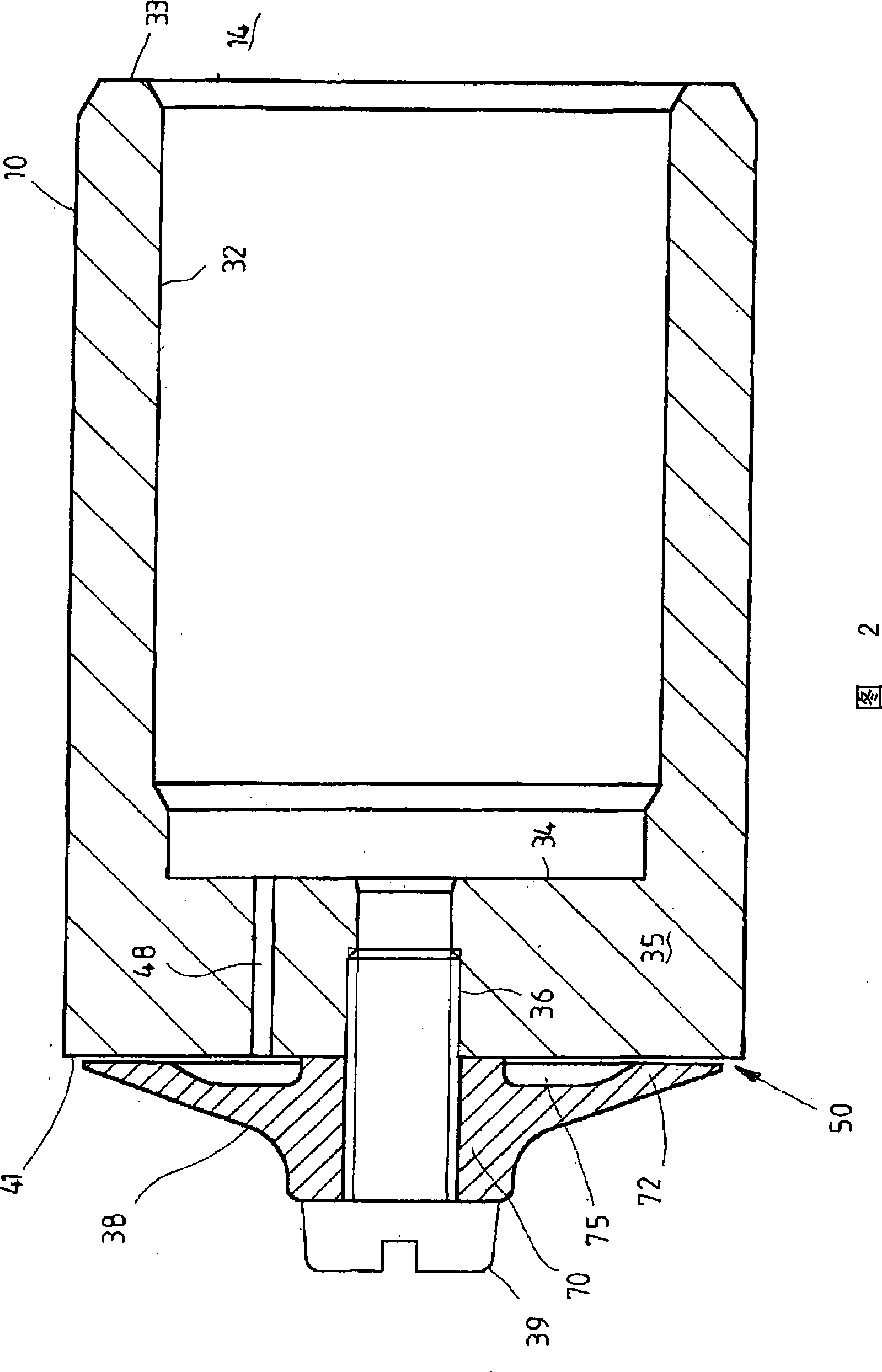

[0070] According to FIG. 1 a , the pilot-operated pressure-limiting valve 1 has a valve body 3 with an inlet connection 5 and a tank connection 6 . A spool is screwed into the valve body 3. The spool is functionally divided into a main stage and a pre-control stage. The main stage essentially consists of a sleeve 8 , in which a main control cone 10 is movably guided. The inner cross section of the sleeve 8 is narrowed in the region of the sleeve 8 facing the inlet connection 5 , so that a valve seat is formed against which the main control cone 10 is pressed in the closed state of the main stage. Radially formed bores 12 are provided in the sleeve 8 , through which pressure medium flows from the inlet connection 5 to the tank connection 6 in the case of an open main stage. The main control cone 10 delimits a spring chamber 14 in a section of the sleeve 8 remote from the inlet connection 5 . In this spring chamber there is a spring 16 which acts on the main control cone 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com