Method for the predictive closed-loop control of a linear drive or of a linear compressor and linear drive or linear compressor subject to predictive closed-loop control

A compressor, linear technology, applied in control systems, AC motor control, electromechanical devices, etc., can solve the problems of reducing efficiency and complexity of linear drives, and achieve the effect of high positioning accuracy and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

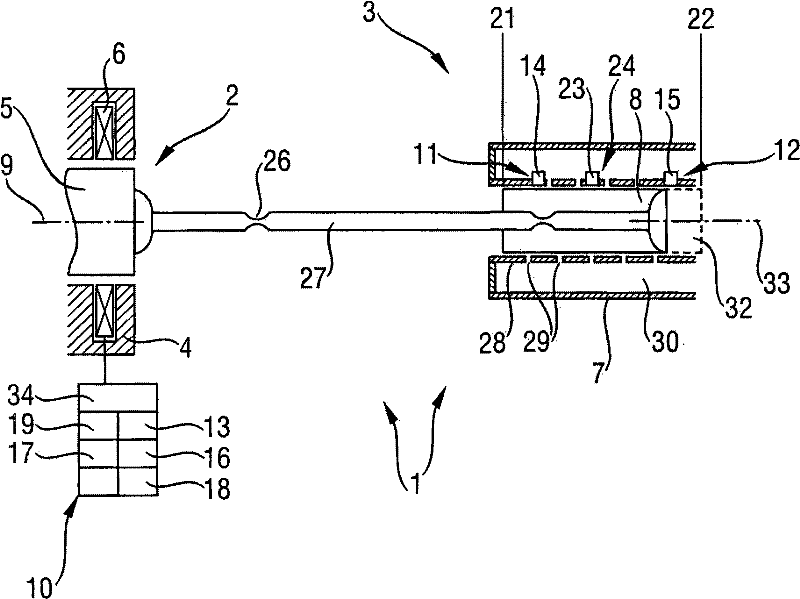

[0059] figure 1A device 1 according to the invention is shown in a sectional view with a linear drive 2 driving a linear compressor 3 for compressing a gaseous fluid 32 . Fluid 32 may be a coolant delivered into a condensation layer (not shown). The linear drive 2 comprises a stator 4 in which a rotor 5 is movable back and forth along a drive axis 9 . The rotor has magnets (not shown) which are moved by means of drive coils 6 .

[0060] The linear drive 2 is connected via a piston rod 27 to a compressor piston 8 which is movable back and forth within the piston housing 7 along a piston axis 33. The piston rod 27 includes a connecting piece 26 formed in the form of a pinch for preventing the compressor piston 8 from tilting. The connecting piece 26 can absorb deflections acting at right angles to the piston rod 27 .

[0061] By means of a housing wall 28 with an opening 29 , the compressor piston 8 is mounted laterally, that is to say in a direction at right angles to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com