Composite paper-cup forming machine with corrugated coat

A technology for compounding paper cups and forming machines, which can be applied to cardboard items and other directions, and can solve the problems of the influence of product appearance and aesthetics, high production cost, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing of description:

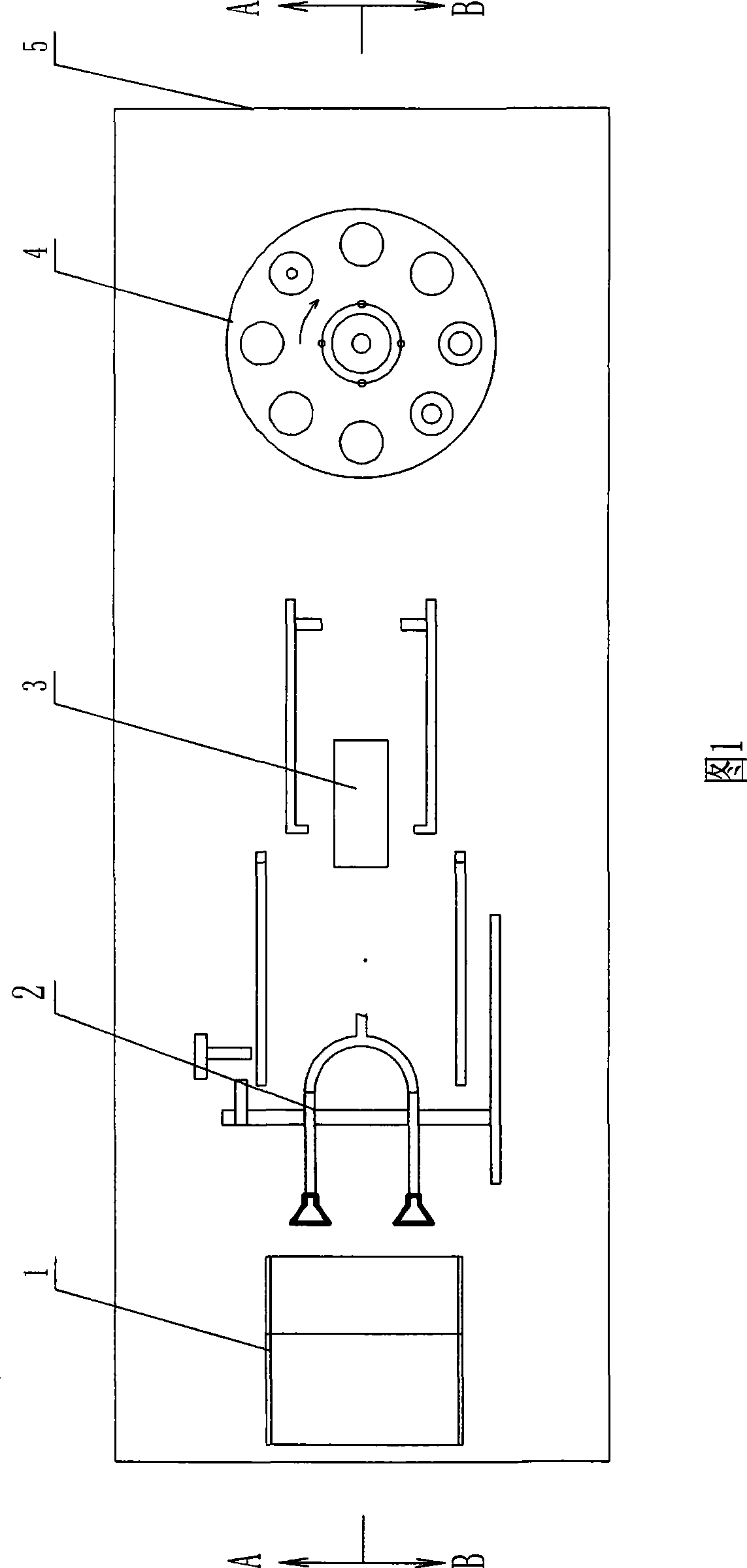

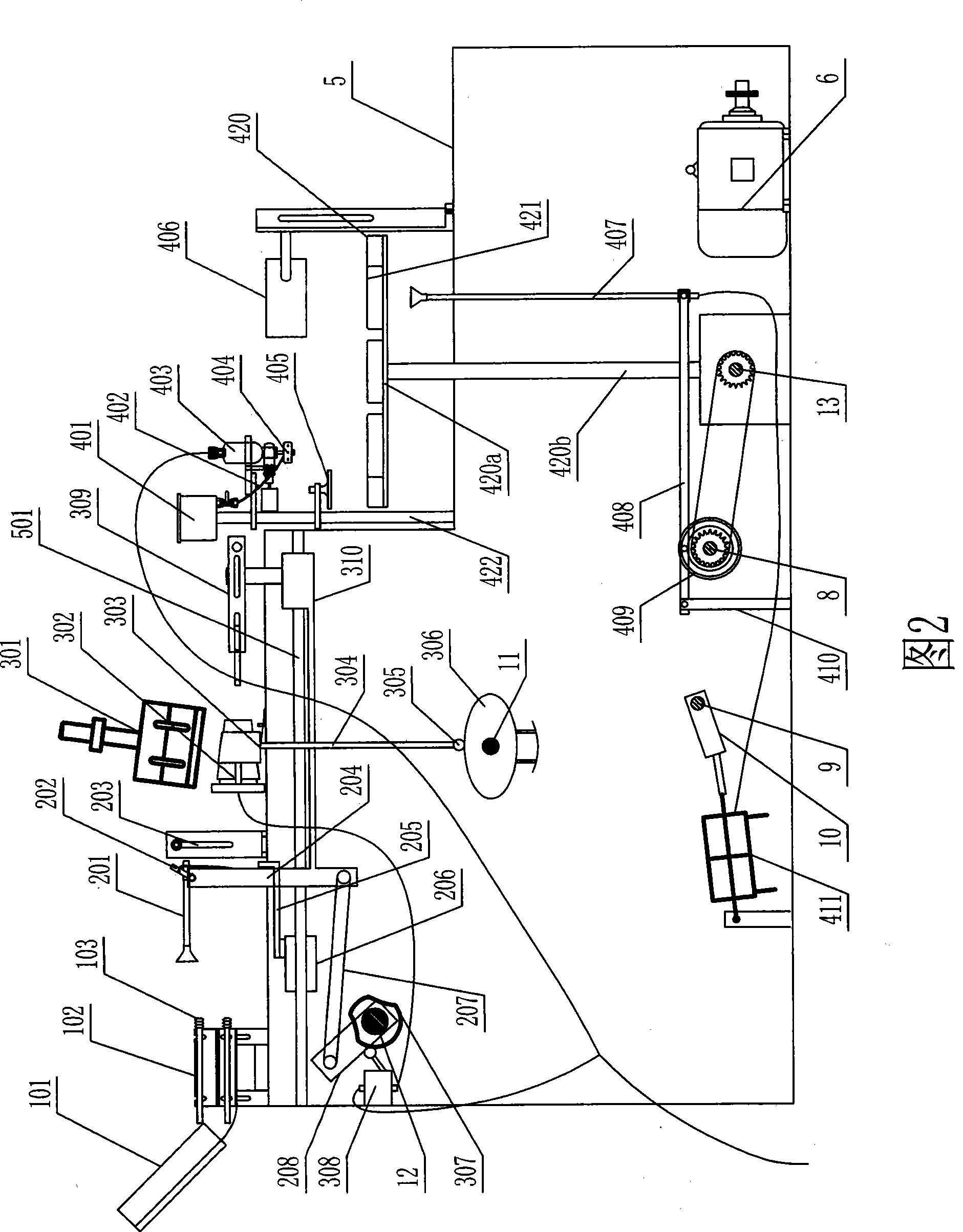

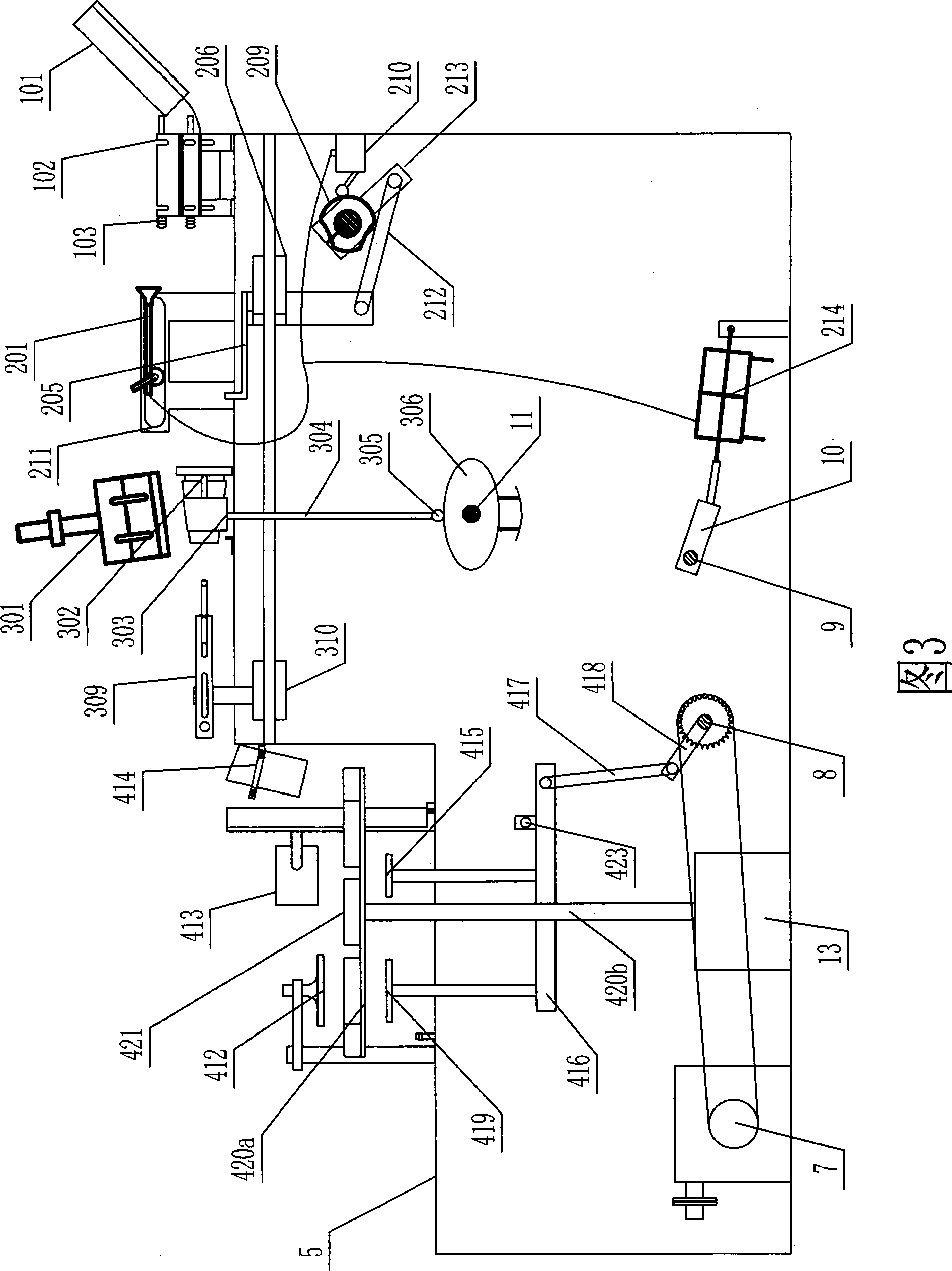

[0024]As shown in Figure 1-6, the transmission mechanism of the corrugated jacket compound paper cup forming machine is driven by the motor 6, and the output shaft of the motor 6 is connected with the compound drive shaft 8 through the gearbox 7, double-row sprockets, and double-row chains. The shaft 8 is connected with the driving shaft 11 of the top package set through the double-row sprockets and double-row chains. The paper suction cylinder 214 and the inner cup cylinder 411 are connected and cooperated with the cylinder drive shaft 9 through the cylinder clamp handle 10 respectively. A slide bar 5a is connected to the left and right in the frame 5. The working surface of the frame 5 is a two-layer stepped structure. The left end of the frame 5 is matched with a paper storage mechanism 1 for storing corrugated paper sheets, and the right side of the paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com