Vibrating roller special for construction of pervious concrete pavement

A technology of permeable concrete and rolling rollers, which is applied to roads, roads, road repairs, etc., can solve the problems of high labor intensity, slow progress, low degree of mechanization, etc., to improve construction efficiency, easy to operate, and avoid manual handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

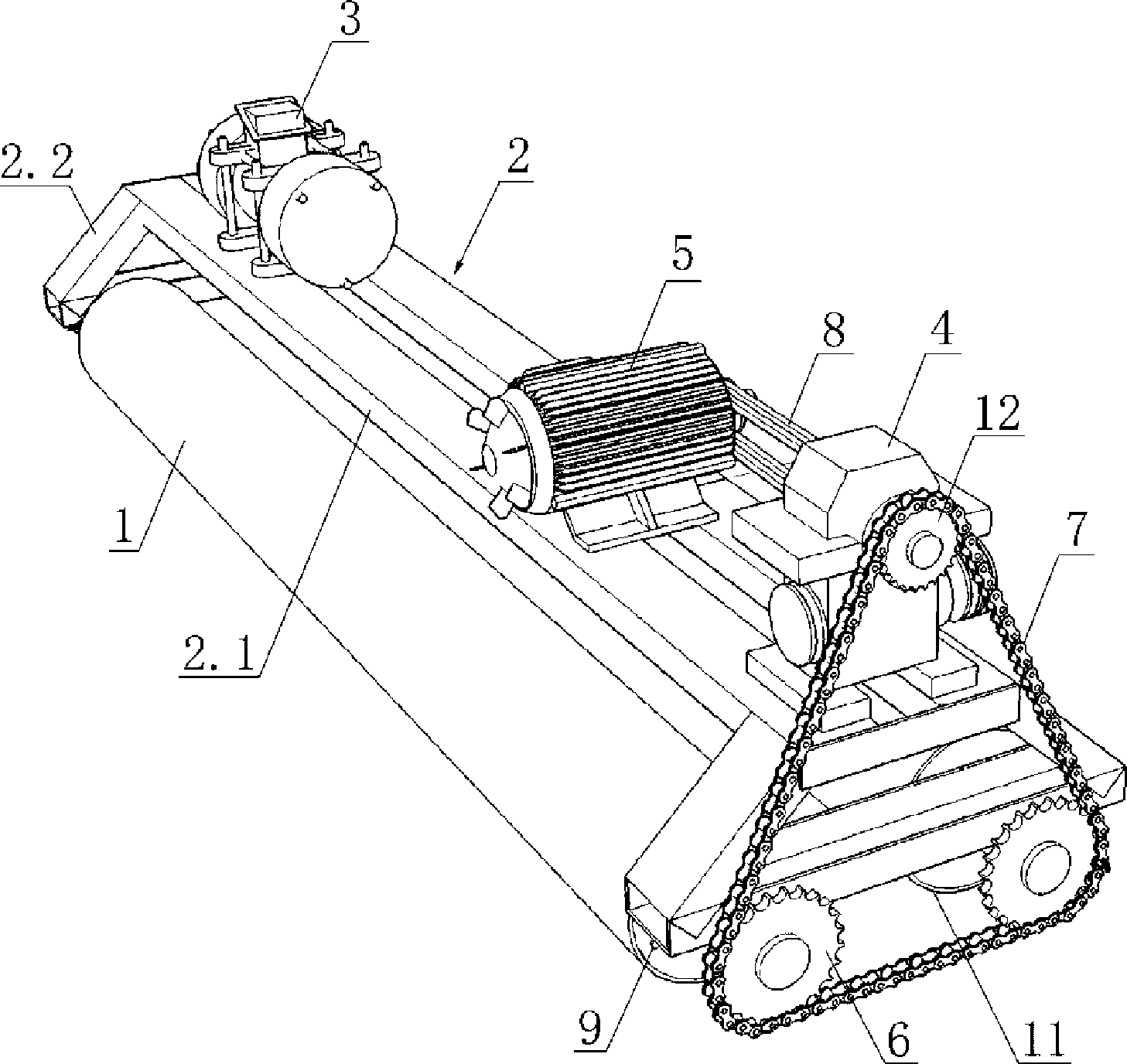

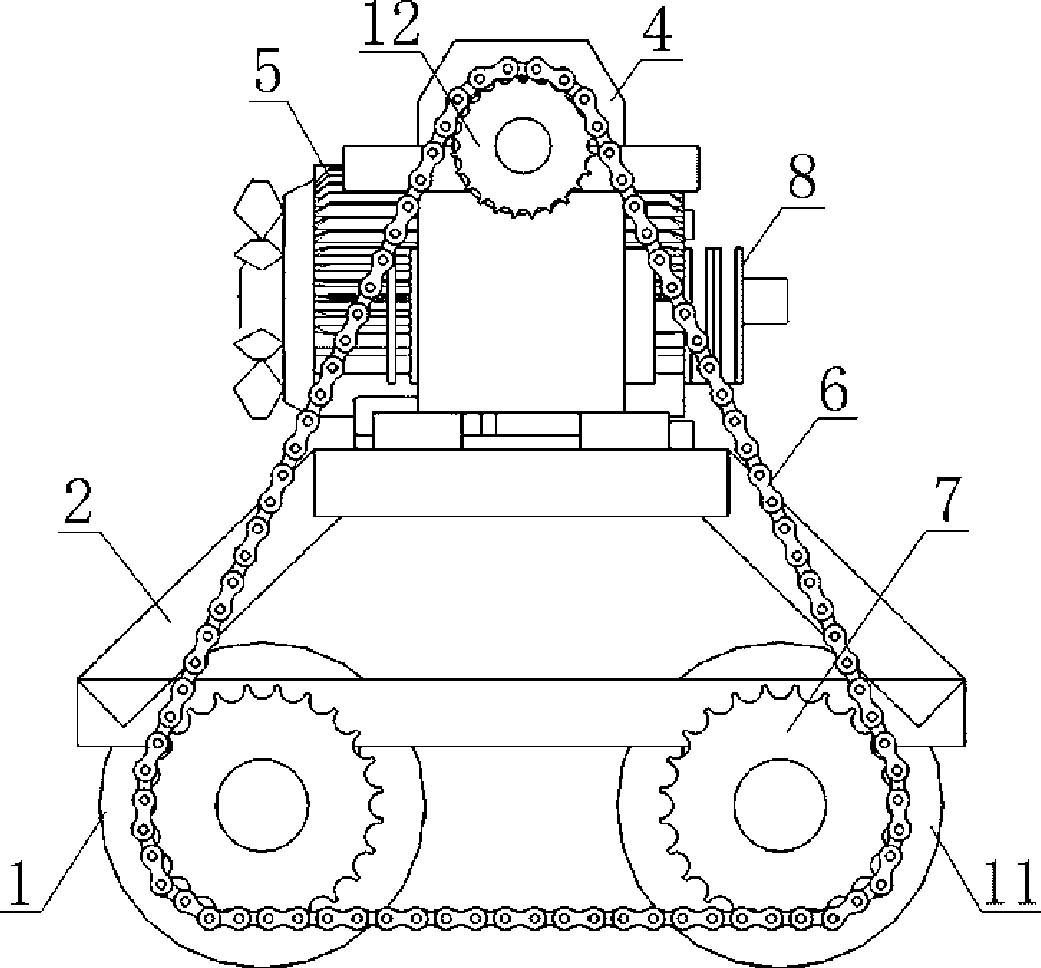

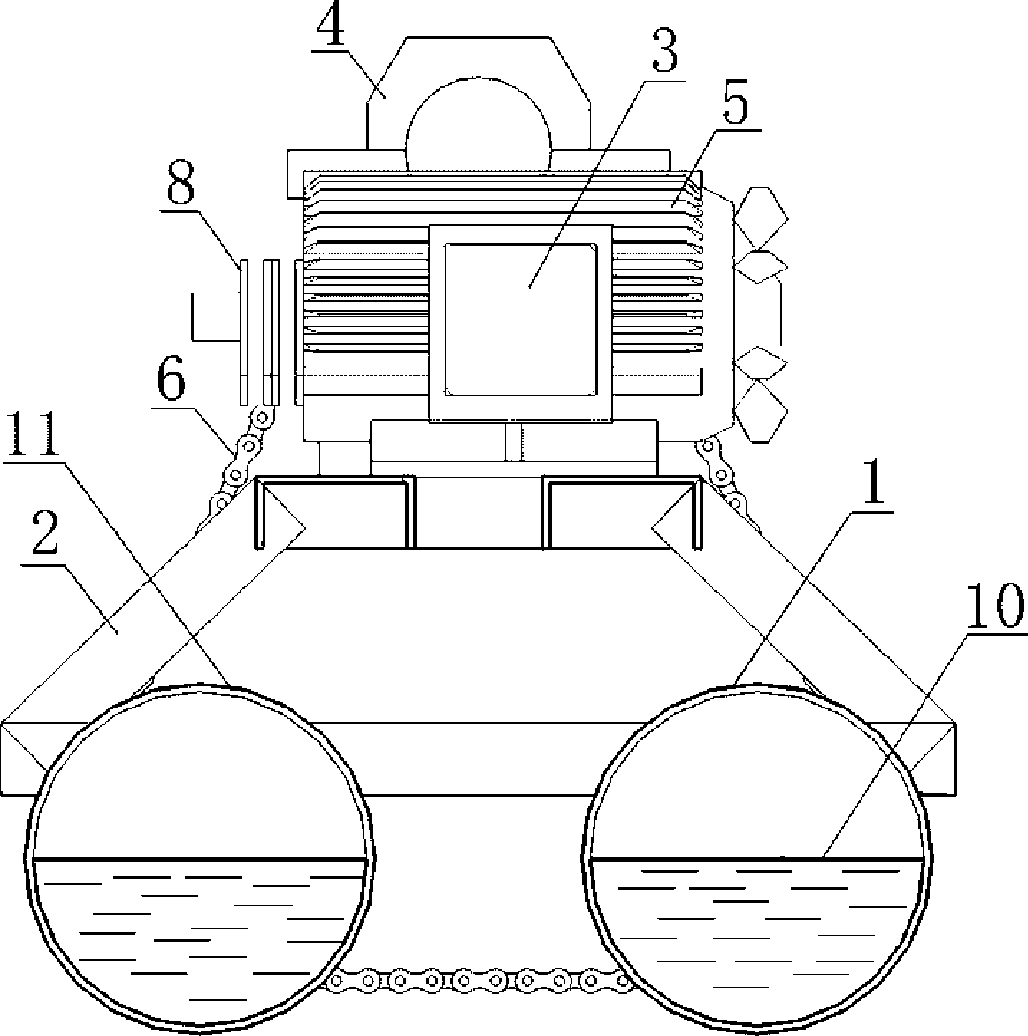

[0022] Examples see Figure 1-Figure 3 As shown, the special vibratory rolling roller for permeable concrete pavement construction includes a frame 2 and a roller connected to the lower part of the frame. Row rollers 11, the sides of the two rollers are provided with a water injection port 9 that communicates with its internal cavity and can be poured into the counterweight water 10, the shafts of the two rollers are connected with the three-phase motor fixed on the frame 2 through the transmission mechanism. The asynchronous motor is driven and connected, and the vibrator 3 is also fixedly connected on the frame.

[0023] The vibrator 3 is fixedly connected to the center of gravity of the frame by bolts. The vibrator selects different powers according to the vibration thickness of the road surface. The greater the power, the greater the exciting force, and 2.5kw and 3kw can be selected. The roller is made of steel pipe, the wall thickness is 5mm, the diameter is 220mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com