Long axis output and electric shaft driven mud pump transmission agent in water

A transmission system and driving technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems that the transmission system is unfavorable to the stability of the central axis, the problem of axial positioning, the shock and torsional vibration of the motor, etc., to achieve Easy replacement of parts, stable operation, and low requirements for axis alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

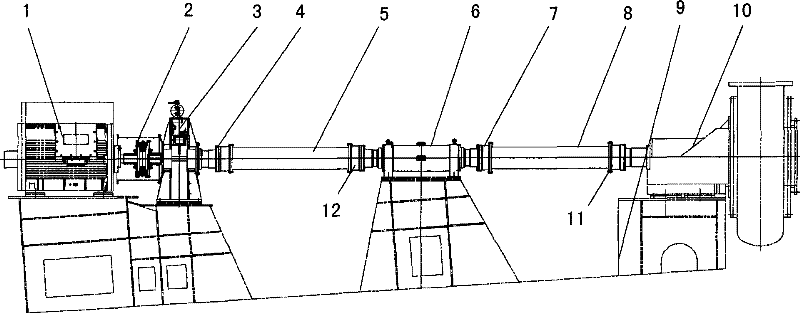

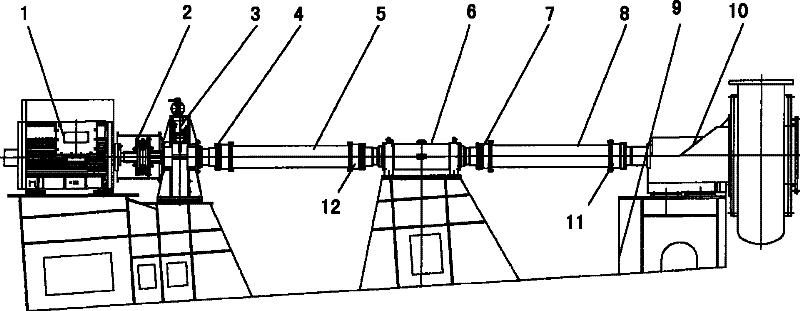

[0024] Such as figure 1 As shown, an embodiment of the electric shaft-driven submerged mud pump transmission system with long shaft output according to the present invention includes a highly elastic coupling 2, a subsea gear box 3, a hollow shaft 5, an intermediate support device 6 and a bridge frame 9 .

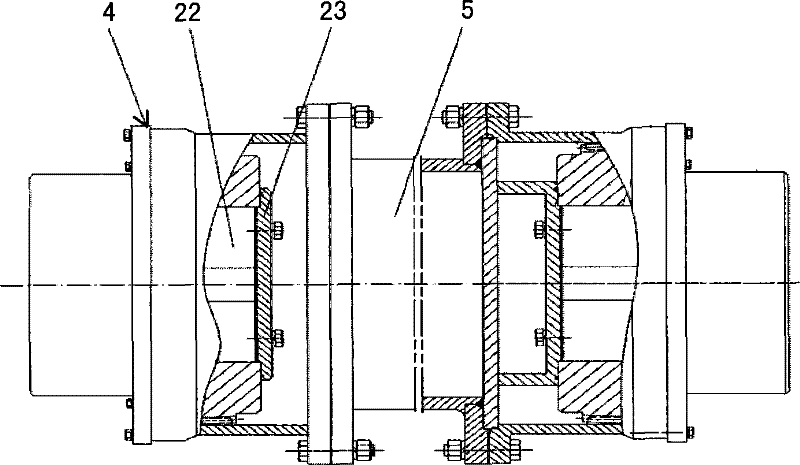

[0025] The electric motor 1 transmits power and rotation speed to the underwater mud pump 10 through the electric shaft driven underwater mud pump transmission system output by the long shaft. The motor 1 is connected to the input shaft of the underwater gearbox 3 through a highly elastic coupling 2 . The output shaft of the underwater gearbox 3 is connected to the left end of the hollow shaft 5 through the drum-shaped tooth coupling 4, the right end of the hollow shaft 5 is connected to the left end of the intermediate support device 6 through the drum-shaped tooth coupling 12, and the right end of the intermediate support device 6 The left end of the hollow shaft 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com