Elastic ground hydrant

A fire hydrant and elastic ground technology, applied in the field of fire hydrants with anti-collision function, can solve the problems of high production cost, complex structure, and no consideration of fire hydrants, etc., and achieve strong pressure resistance, small investment in technical transformation, and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

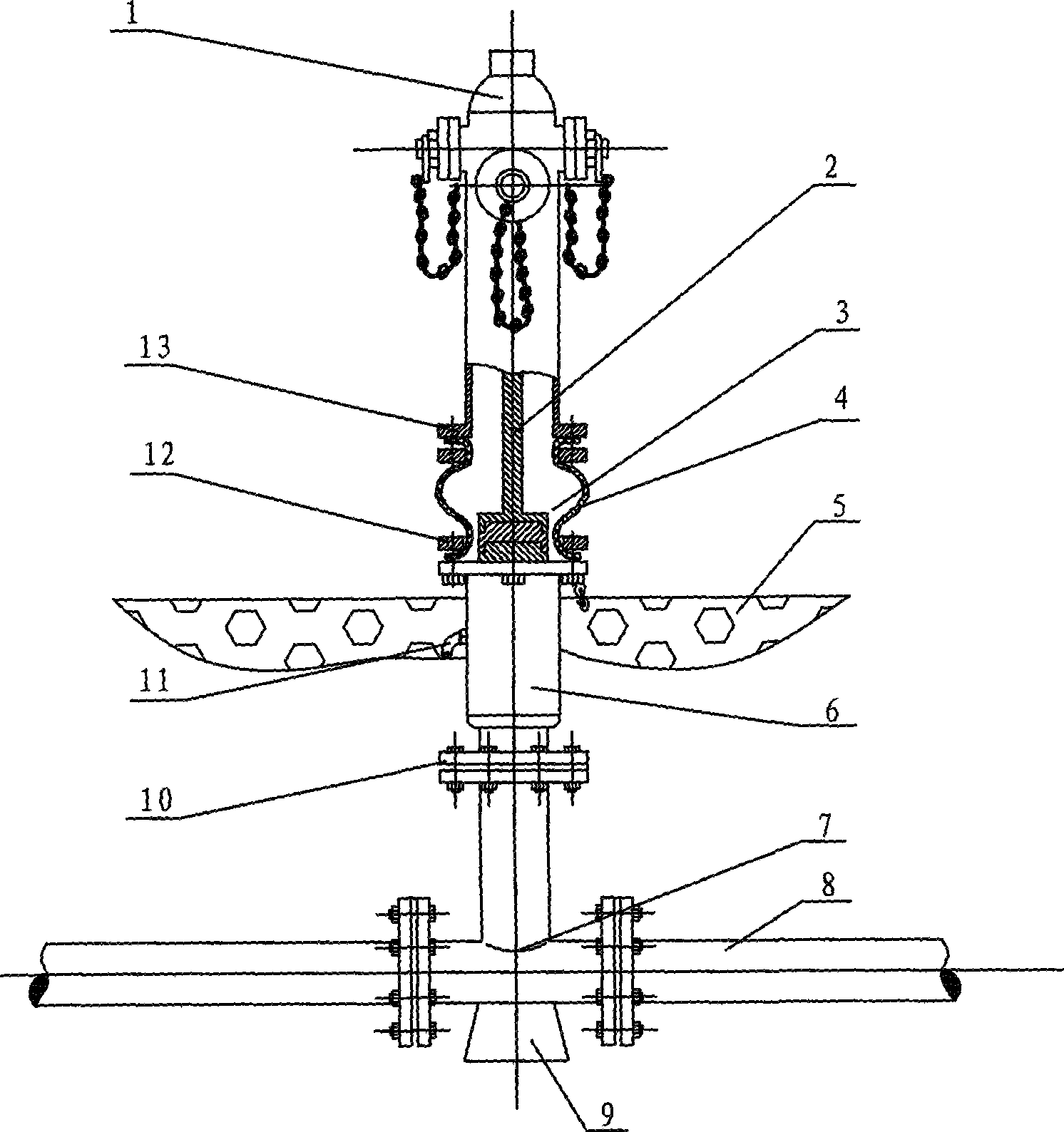

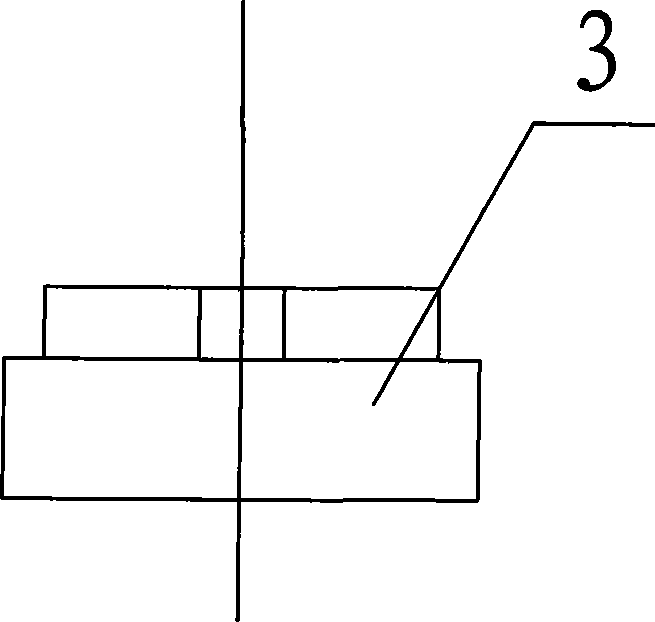

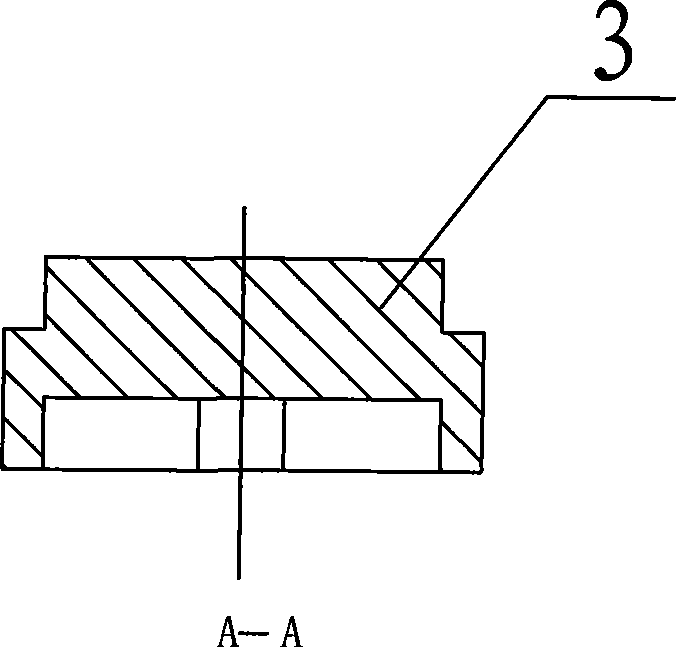

[0013] The elastic above-ground fire hydrant is composed of a fire hydrant body 1, a reducing pipe 6, a fire hydrant connecting water pipe 7, a valve stem 2, a one-way valve, a rubber joint pipe 4 and a rubber cross 3. The fire hydrant body 1 and the rubber joint pipe 4, the rubber joint pipe 4 and the reducer pipe 6, the reducer pipe 6 and the fire hydrant connection water pipe 7 are respectively connected by flanges 13, 12 and 10, and the rubber joints Tube 4 is made of nitrile rubber with lead hair. The rubber ten-byte 3 is made of nitrile rubber with lead hair. It has a raised "cross" fork on its upper surface and a sunken "cross" fork on its lower surface. The valve stem 2 A recessed "cross" fork is provided at the tail end to engage with the upper part of the rubber ten word 3, and a raised "cross" fork is provided at the top of the one-way valve opening mechanism 11 to engage with the lower part of the rubber ten word 3. The top of the valve stem 2 extends to the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com