Grouting pile sandwich panel wave barrier

A technology of sandwich panels and expanded piles, which is applied in the fields of basic structure engineering, building components, and earthquake resistance, can solve the problems of low vibration isolation efficiency, achieve improved vibration isolation effects, low cost, and ensure safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

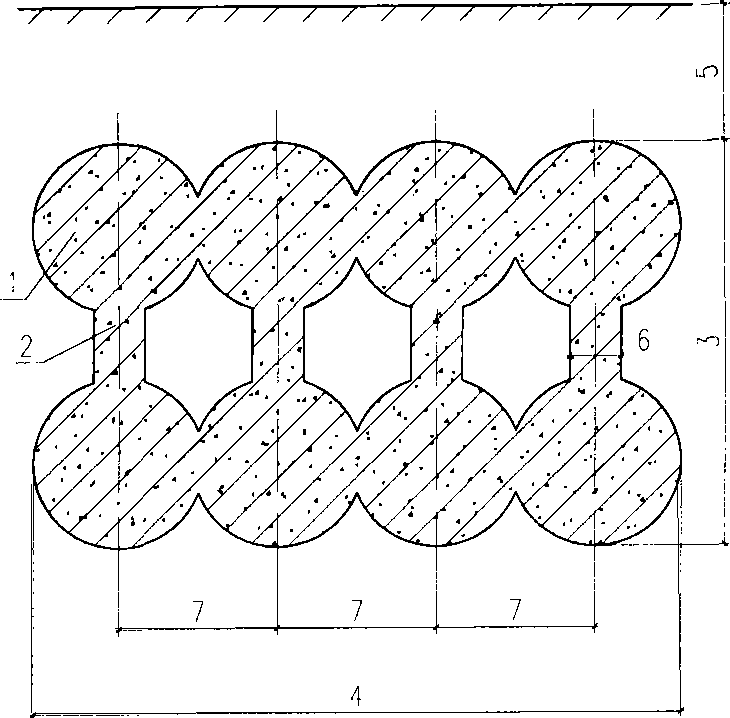

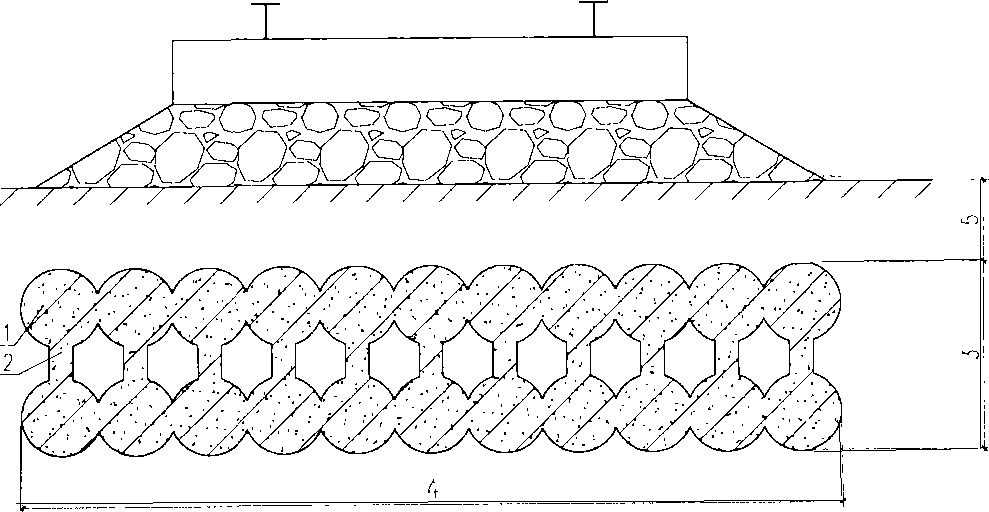

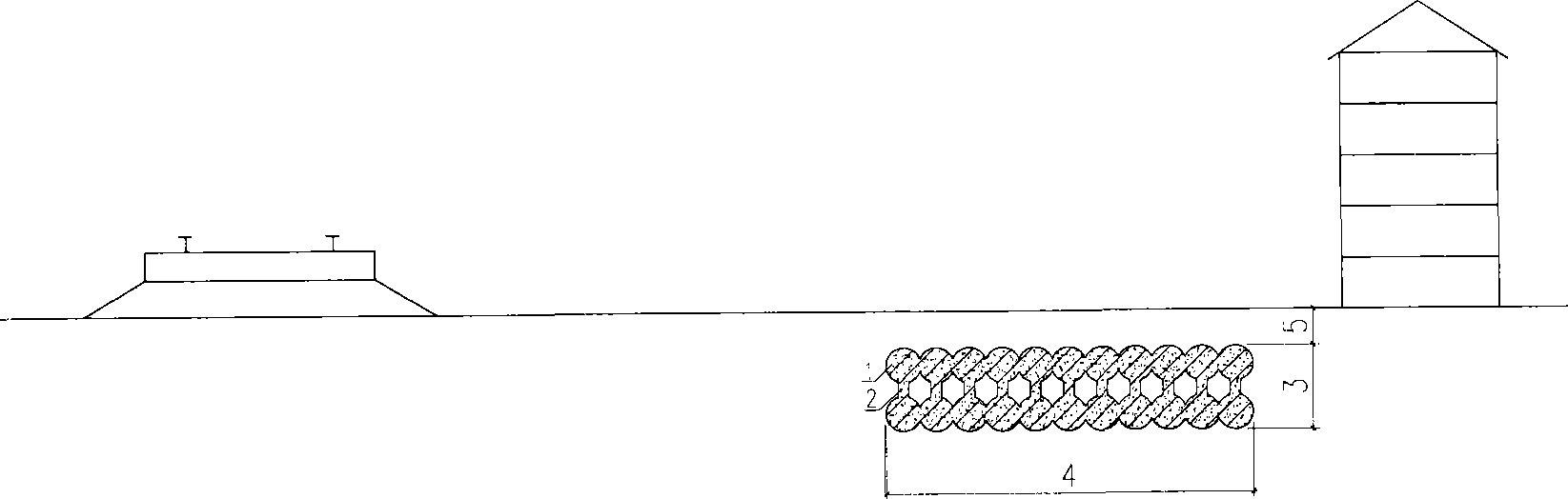

[0018] Provide embodiment of the present invention as follows in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, the sandwich panel wave barrier described in this embodiment is composed of a plurality of piles 2 arranged side by side, and the upper and lower ends of each pile 2 are spherical or disc-shaped expansion bodies 1, and the adjacent two expansion bodies Body 1 is connected to form a sphere or a convex disc. The board surface of the expansion body 1 is of uneven structure, which can make a part of the reflected waves reflect each other in the soil and convert them into heat energy dissipation to reduce the reflection and focusing of the wave front, thus further improving its vibration isolation effect. The pile body 2 is the concrete pouring pile commonly used for building foundations, and the length and spacing of the pile body are determined by the vibration isolation design. The expanding body connected to the pile body 2 is generally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com