Sand prevention water injection packer

A packer and sand control technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as well stuck accidents, packer damage, and large well washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

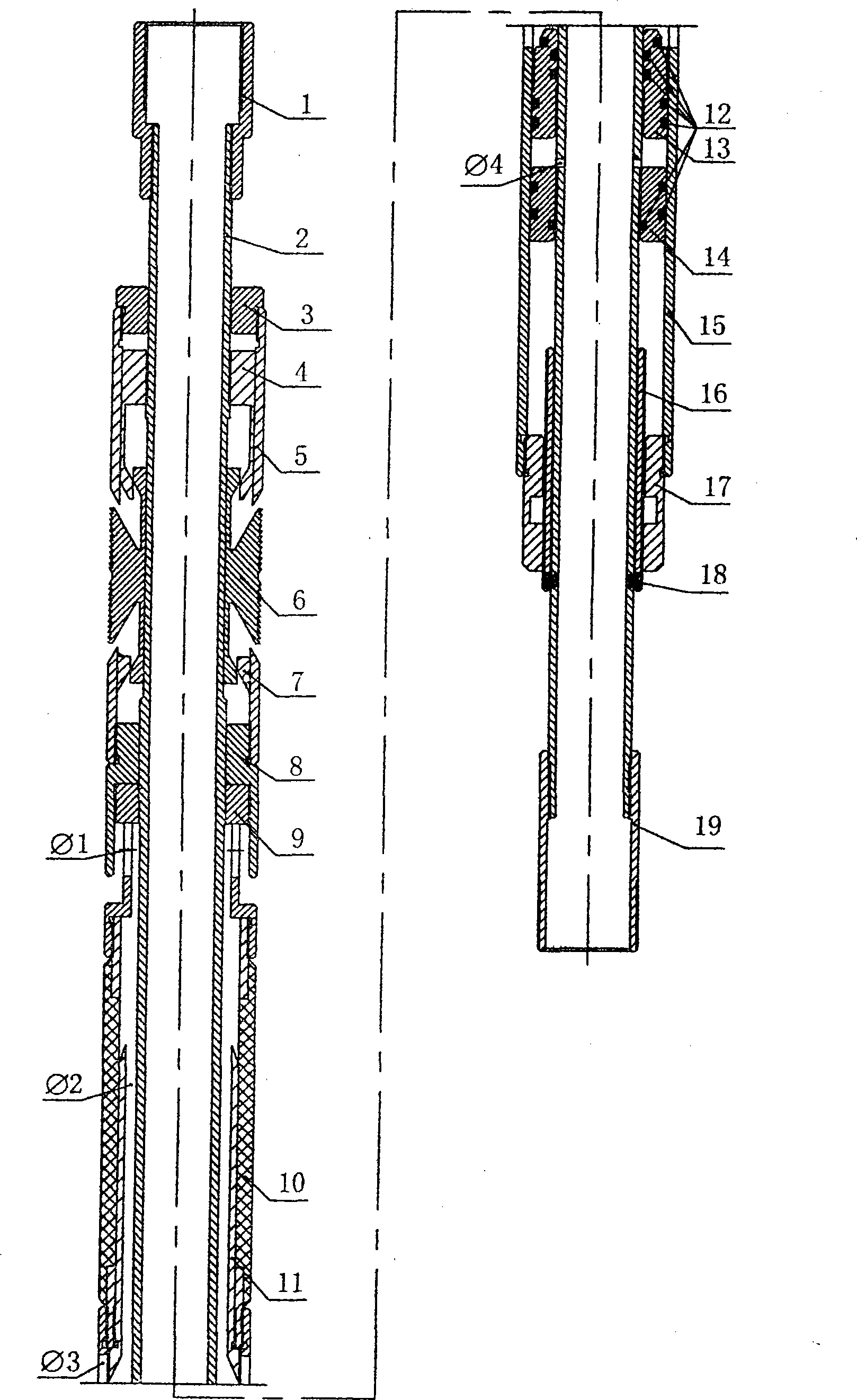

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] In the embodiment shown in FIG. 1 , the central pipe 2 has external threads at both ends and the middle and lower parts, and has pressure transmission holes Φ4 and round holes at the middle and lower parts. Slip telescoping sleeve 4 is that one end internal diameter is small and has internal thread, and the middle internal diameter is big, and the internal diameter of the other end is less than the internal diameter of the middle part, and its transition section is the bell mouth of internal cone surface, and the end is external conical surface. The main body of the anchor 5 has internal threads at both ends, and the outer circle of the middle part is vertically symmetrical with two sides being straight faces, and the two ends are trapezoidal grooves with an outer conical inclined plane. Slips 6 are planes on both sides, with clamping teeth on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com