Oil field perforating bullet body powder metallurgy material and perforating bullet body manufacturing method

A technology of powder metallurgy and perforating charges, applied in the field of perforating charges, can solve the problems of easy well sticking, reduced mining efficiency, and many production processes, and achieves the effects of reducing oil production cost, avoiding well sticking accidents, and scientific and reasonable formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

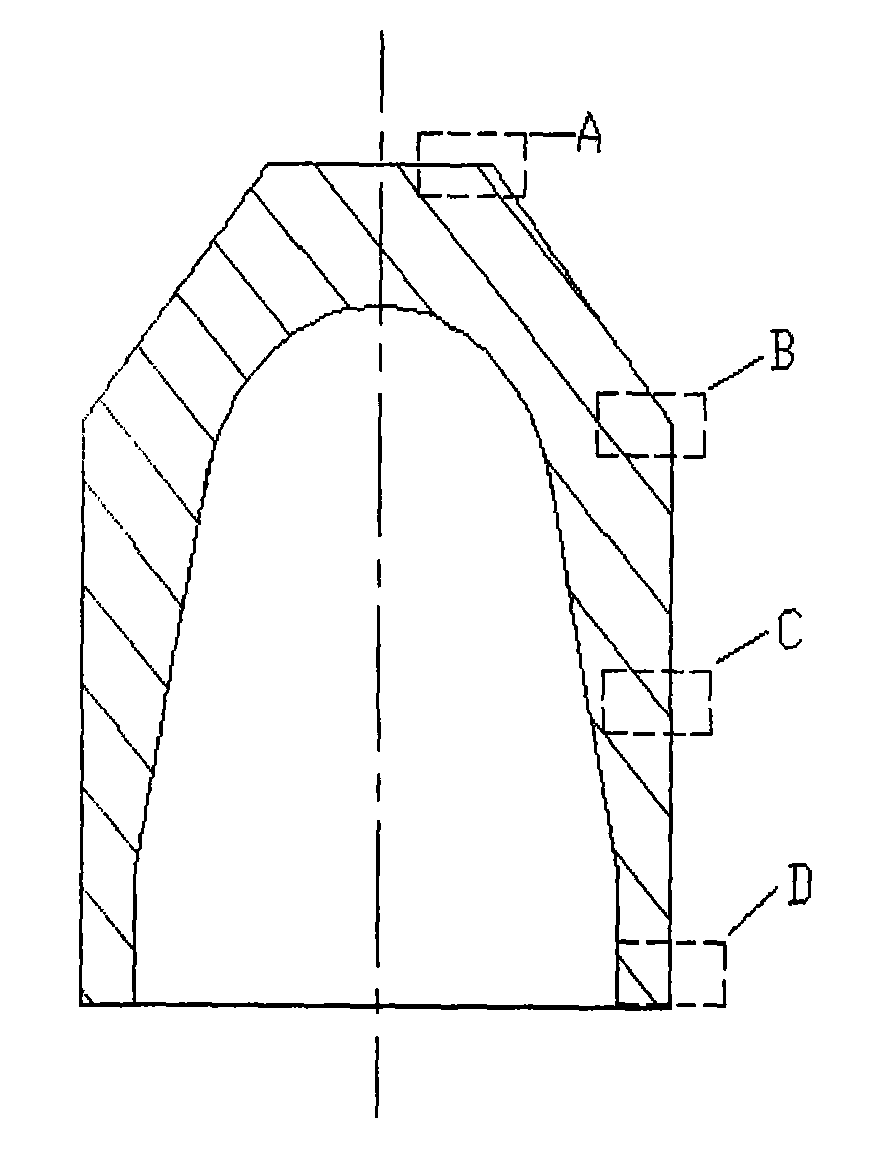

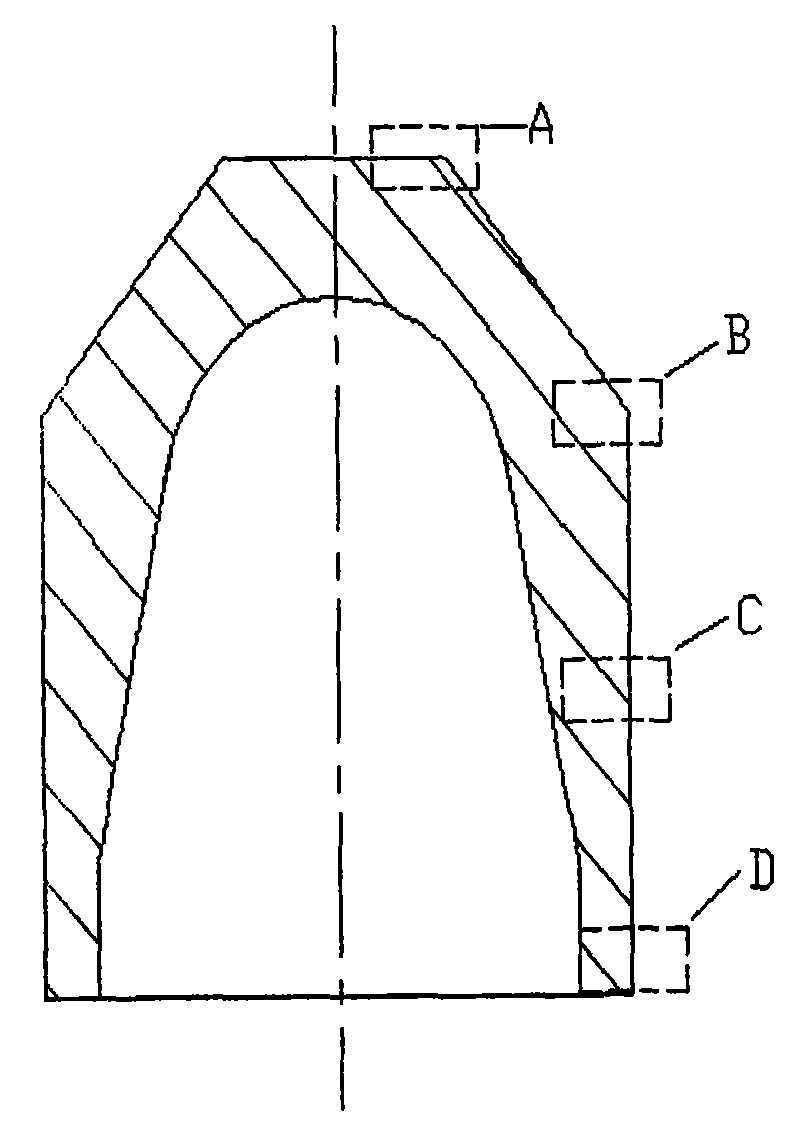

Image

Examples

Embodiment Construction

[0008] Examples are given below to describe the present invention in detail.

[0009] Take by weighing 20 kilograms of copper powder, 20 kilograms of nickel powder, 8 kilograms of graphite powder, 10 kilograms of rare earth powder, and 942 kilograms of iron powder, a total of 1000 kilograms for use, and the percentages of each component in the total weight are 2%, 2%, 0.8%, 1% and 94.2%, the particle size of iron powder is less than 100 mesh, and the particle size of copper powder, nickel powder, graphite powder and rare earth powder is less than 200 mesh. During processing, all the copper powder, nickel powder, graphite powder, rare earth powder and iron powder raw materials in the formula are mixed for 2 hours at a speed of 72 revs / min through a V-shaped mixer to prepare an elastic body pressing material; The above-mentioned mixed metal raw material components are pressed and sintered by the primary mold, and processed into a projectile blank. The initial pressure is 500Mpa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com