Method and device for ensuring measurement and adjustment precision of flow on water distributor

A technology to ensure the flow rate and water distribution device, which is applied in the directions of measurement, mining fluid, earthwork drilling, etc. It can solve the problems of unstable flow measurement and adjustment, small righting force, poor effect, etc., and achieve improved safety, large righting force, and improved Effects of Accuracy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

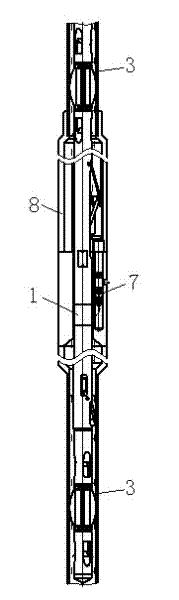

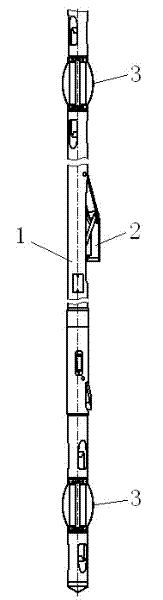

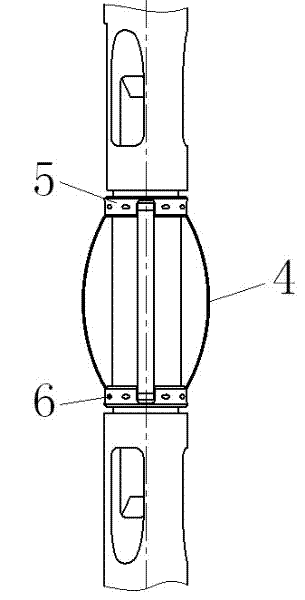

[0018] Embodiments of the present invention: A method of ensuring the accuracy of flow measurement and adjustment on the water distributor of the present invention is to ensure the accuracy of flow measurement and adjustment by stabilizing the posture of the instrument in the oil pipe and making the instrument located in the middle of the oil pipe; it stabilizes the instrument The posture in the oil pipe is realized by the upper and lower righting devices; the instrument is located in the middle of the oil pipe through the shrapnel evenly distributed along the circumferential direction to ensure that the radial force of the instrument is uniform, so that the instrument is always in the center of the oil pipe.

[0019] A kind of device used in the method of the present invention to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com