Method for making a composite airfoil

A technology of airfoils and composite wings, which is applied to pump components, household components, engine components, etc., and can solve problems such as corrosion and erosion of airfoils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

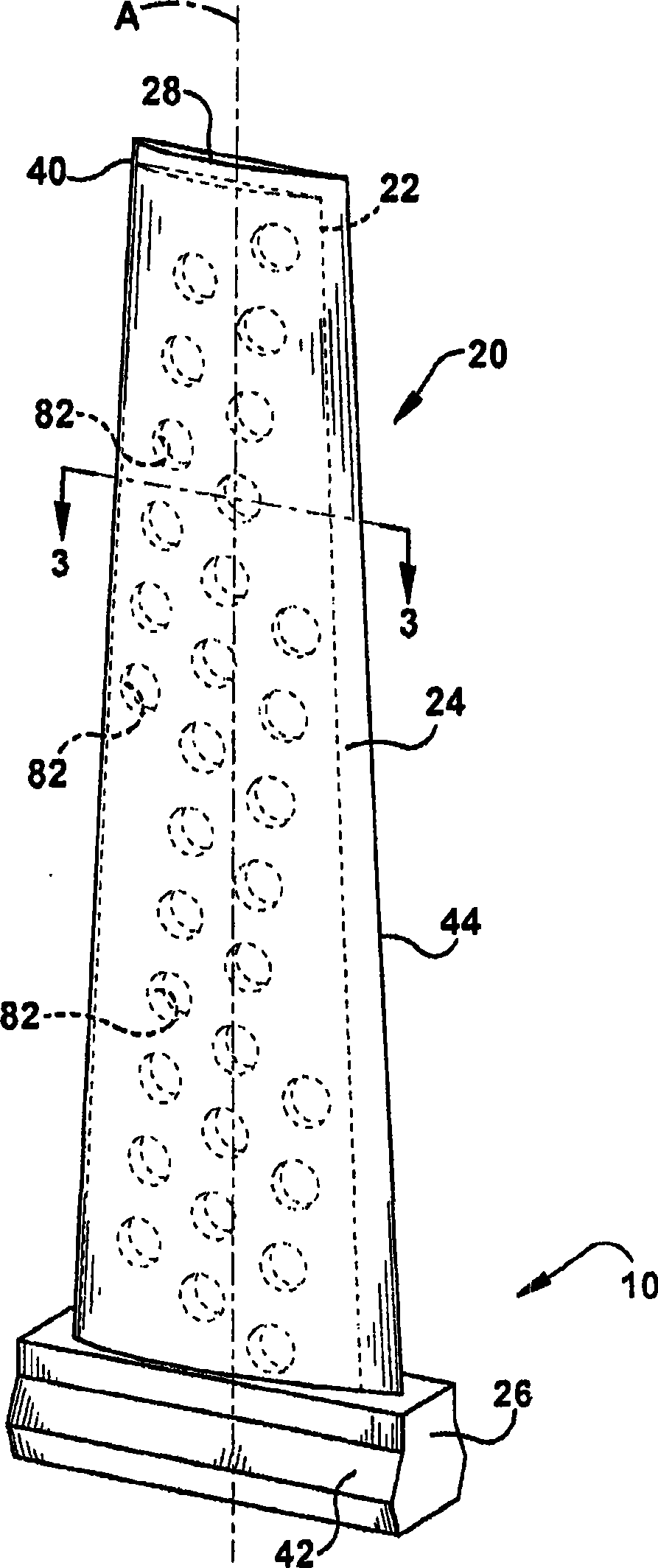

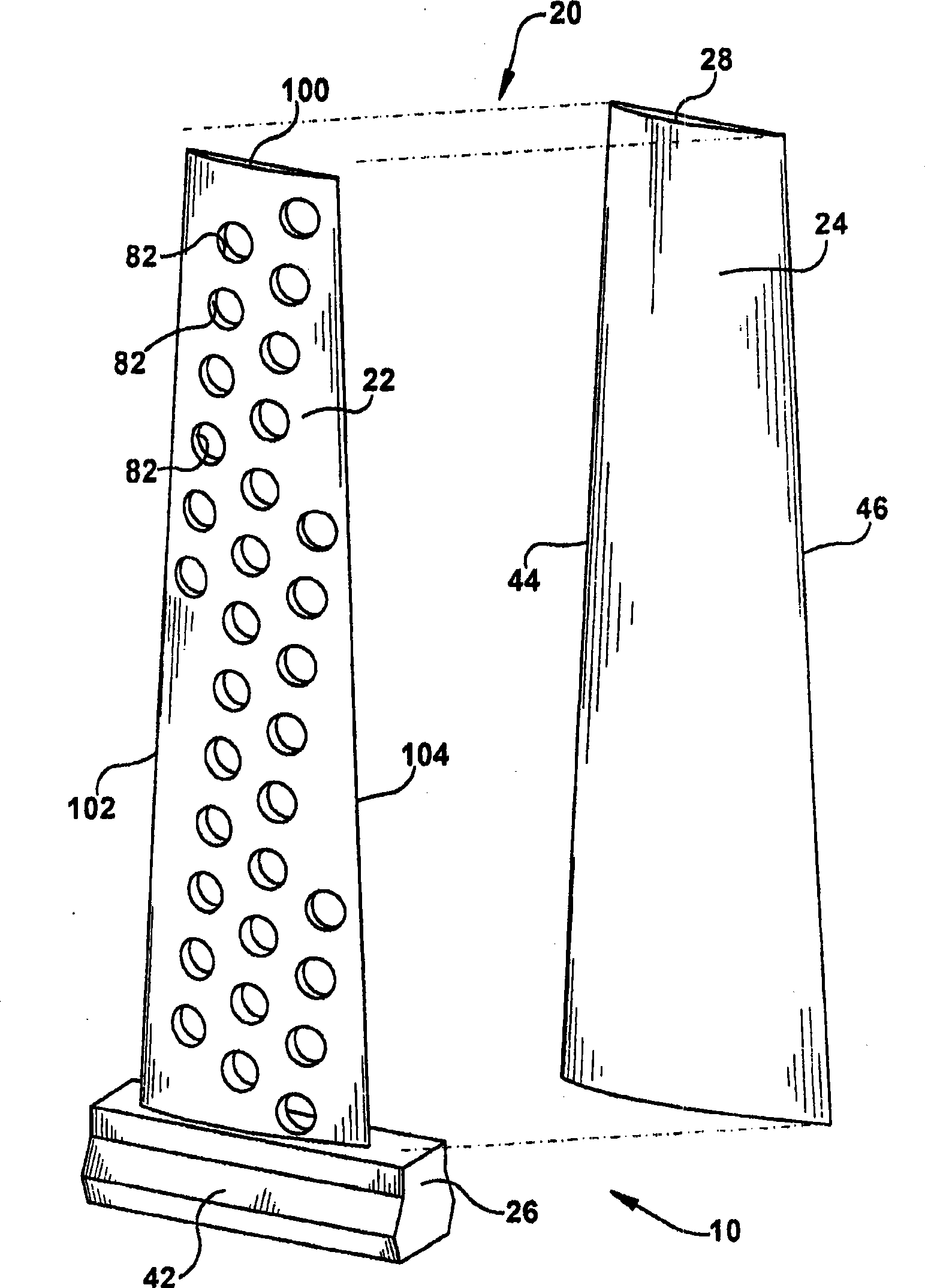

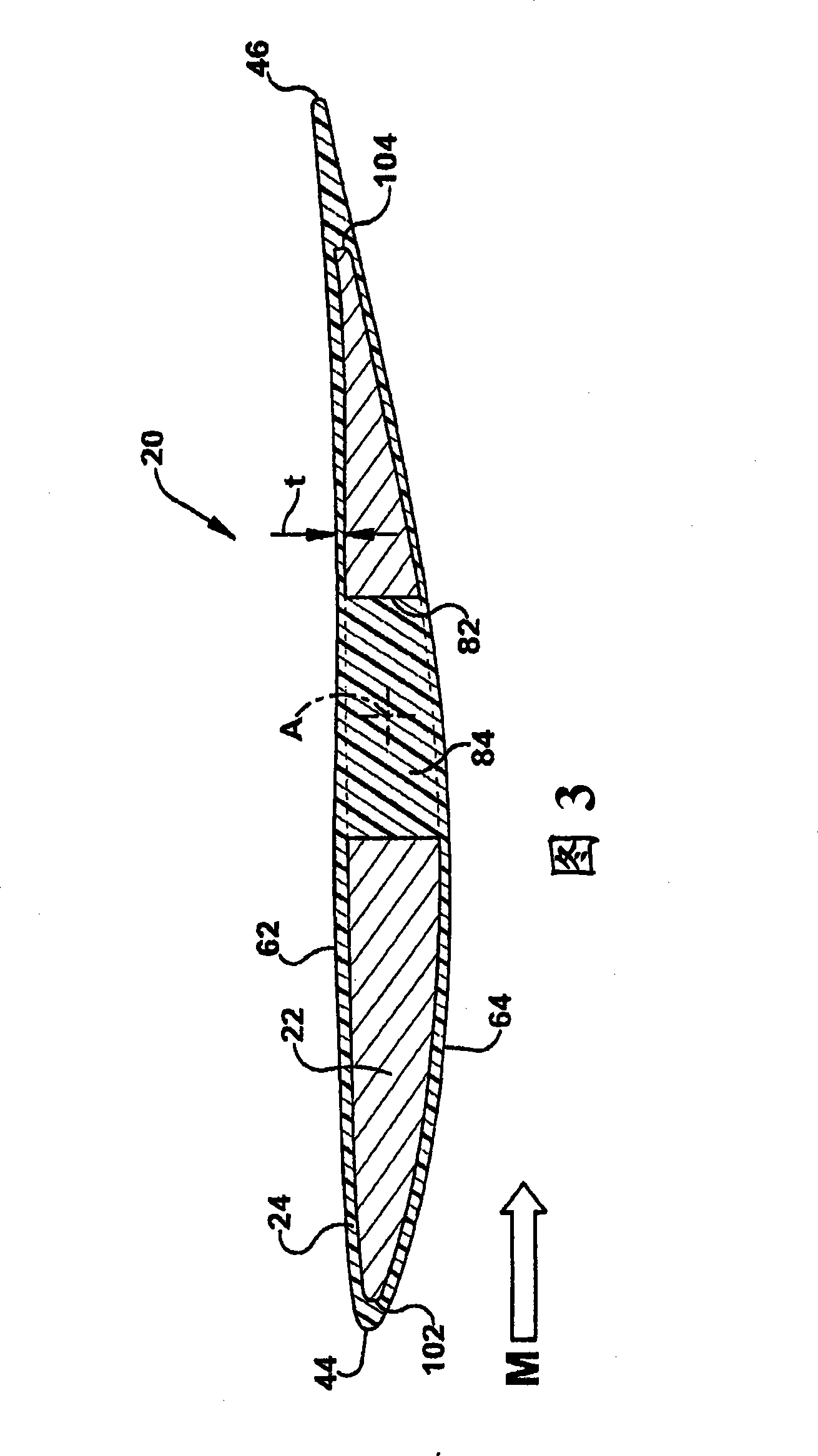

[0020] According to one aspect of the present invention, figure 1 The composite airfoil 20 shown in is part of a blade 10 for a gas turbine used in power generation applications. It should be appreciated that the composite airfoil 20 of the blade 10 in various aspects of the invention may be in the form of a compressor blade, vane or turbine blade and may be used in steam turbine, gas turbine or wind turbine applications. According to one aspect, the composite airfoil 20 of the blade 10 includes a core 22 and a plastic airfoil portion 24 completely surrounding and encapsulating the core.

[0021] Composite airfoil 20 is made in a unique fashion from at least two different materials. “Composite” as used herein is defined as having a plastic material form the polished airfoil portion 24 positioned over a relatively rigid structural material (eg, metal or ceramic) of the core 22 . The term "plastic" is defined as being able to melt at a temperature relatively below the melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com