Combustor for stove

A burner and burner head technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of difficult cleaning and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

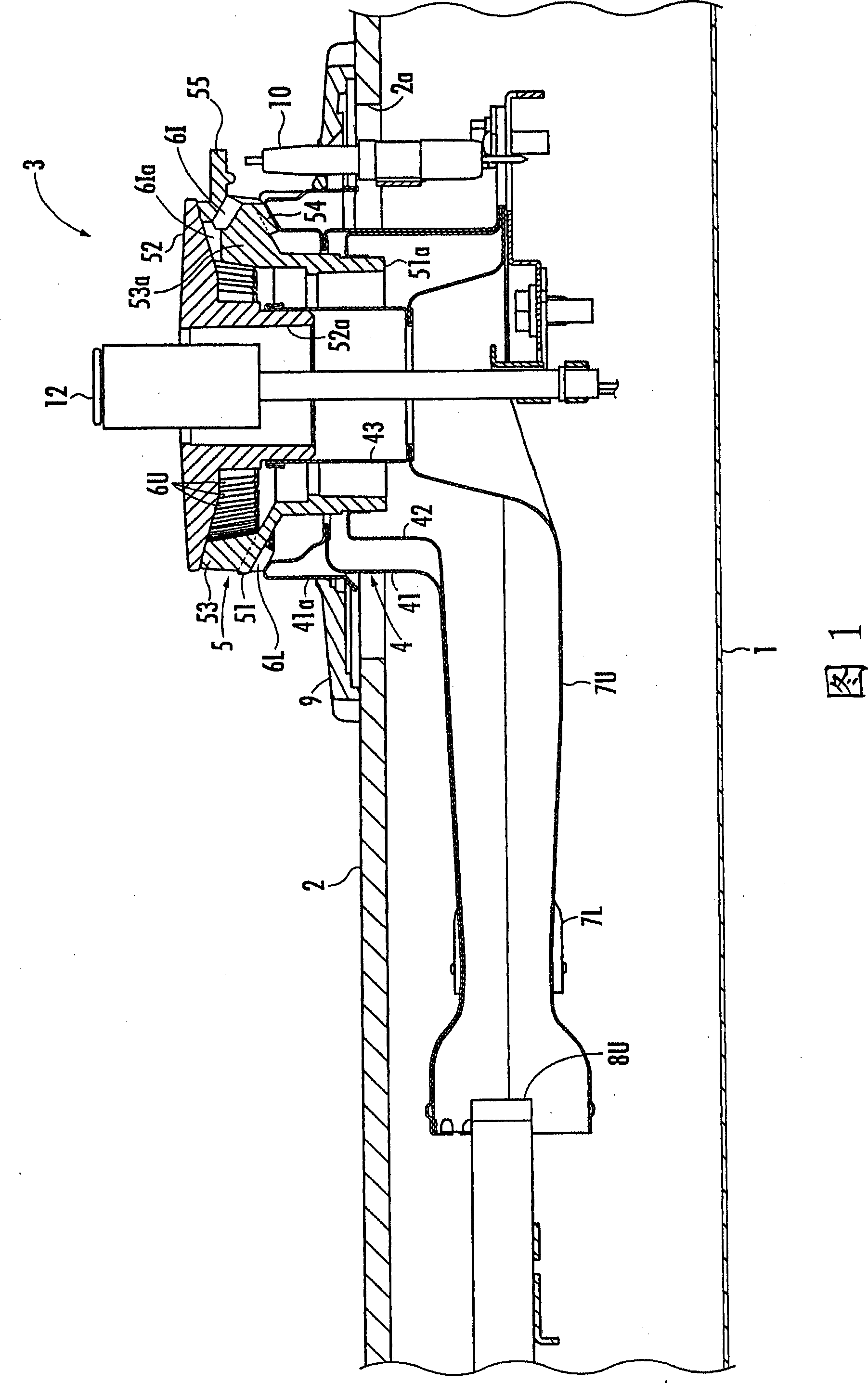

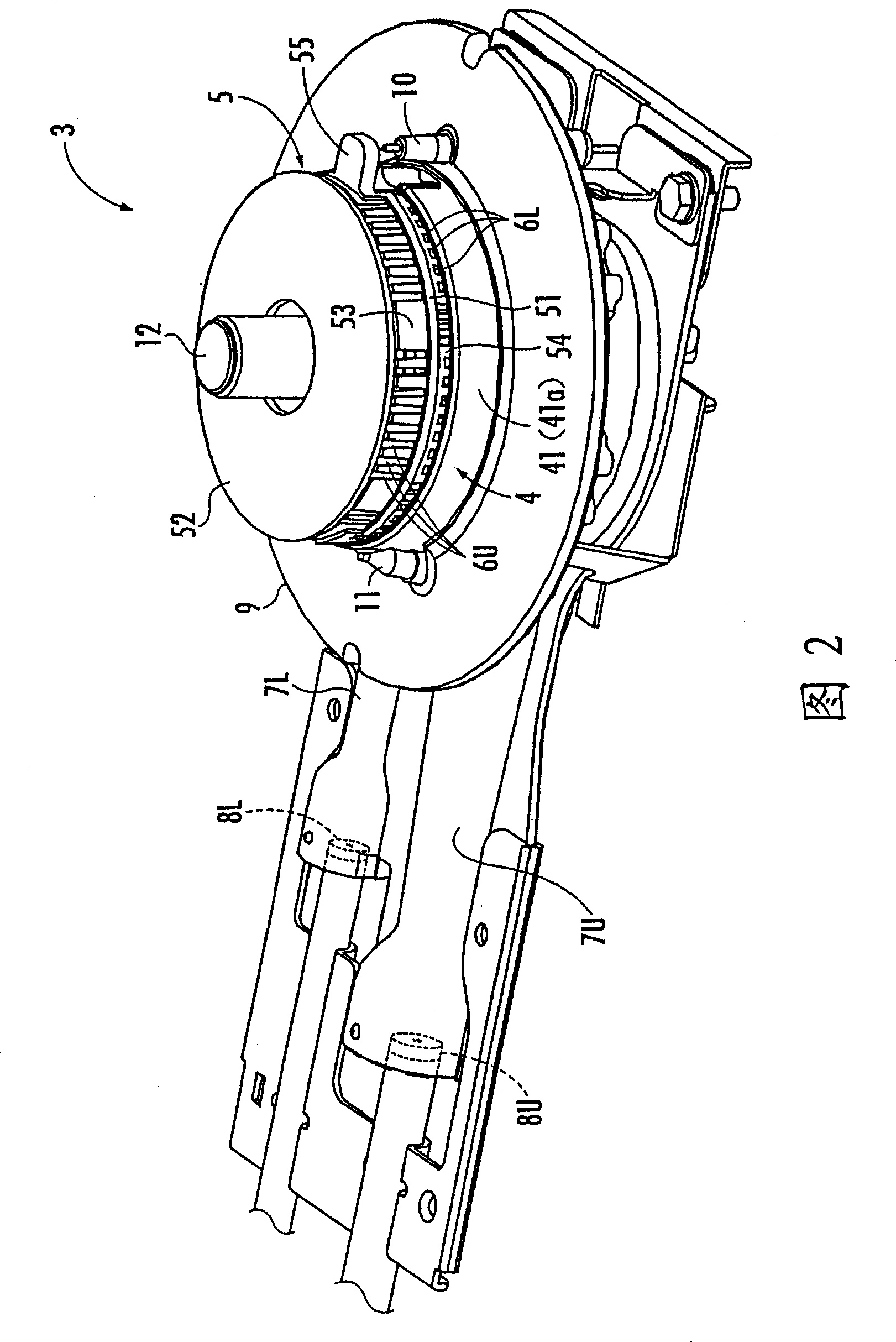

[0027] Referring to FIG. 1 , 1 denotes a stove main body, 2 denotes a panel covering the upper surface of the stove main body 1 , and 3 denotes a burner for a stove. In the panel 2, the opening 2a for burners is opened. In addition, on the panel 2, a bracket (not shown in the figure) is placed so as to surround the burner opening 2a. Furthermore, the cooking vessel placed on the stand is heated by the burner 3 .

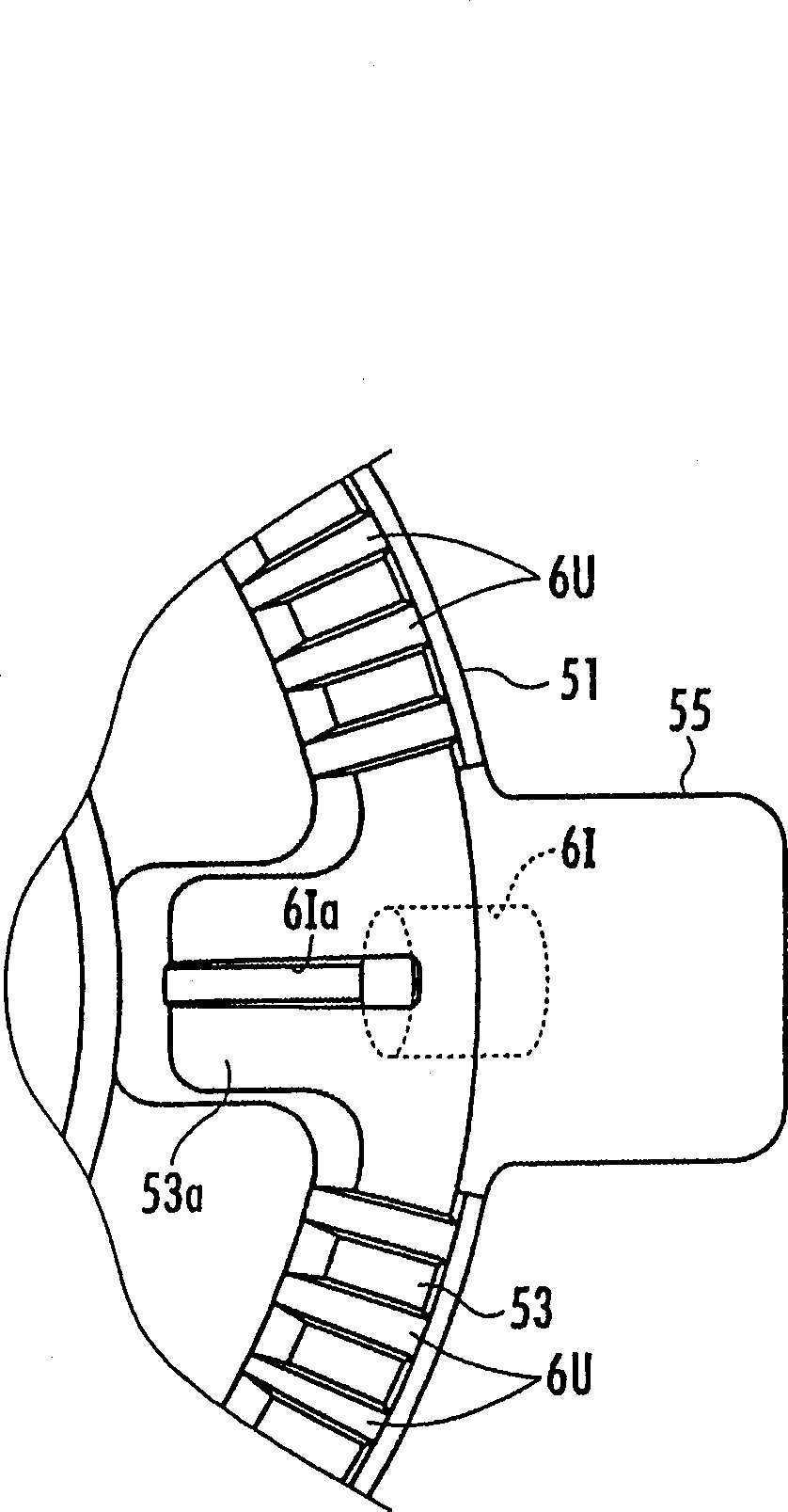

[0028] The burner 3 has a burner body 4 and a burner head 5 on the burner body 4 , wherein the burner body 4 passes through the burner opening 2 a. On the circumferential surface of the burner head 5, as shown in Figure 2, there are a plurality of flame ports 6U, 6L in the upper and lower layers, and an ignition flame port 6I is opened in one of the circumferential directions, wherein the upper and lower layers The plurality of flame ports 6U, 6L of the layer are each spaced apart in the circumferential direction. Here, the upper layer flame port 6U is not provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com