Automobile vehicle body structure fatigue life predicting system

A fatigue life prediction, automobile body technology, applied in the system field of the automotive engineering technology field, can solve problems such as the deviation of the fatigue life prediction value, the inability to accurately predict the fatigue life, and the lack of biaxial analysis, etc., and achieve strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the implementation process of the present invention is described in detail: this example is carried out under the premise of technical solution of the present invention, has provided detailed embodiment and concrete operation process, but protection scope of the present invention is not limited to following Example implementation.

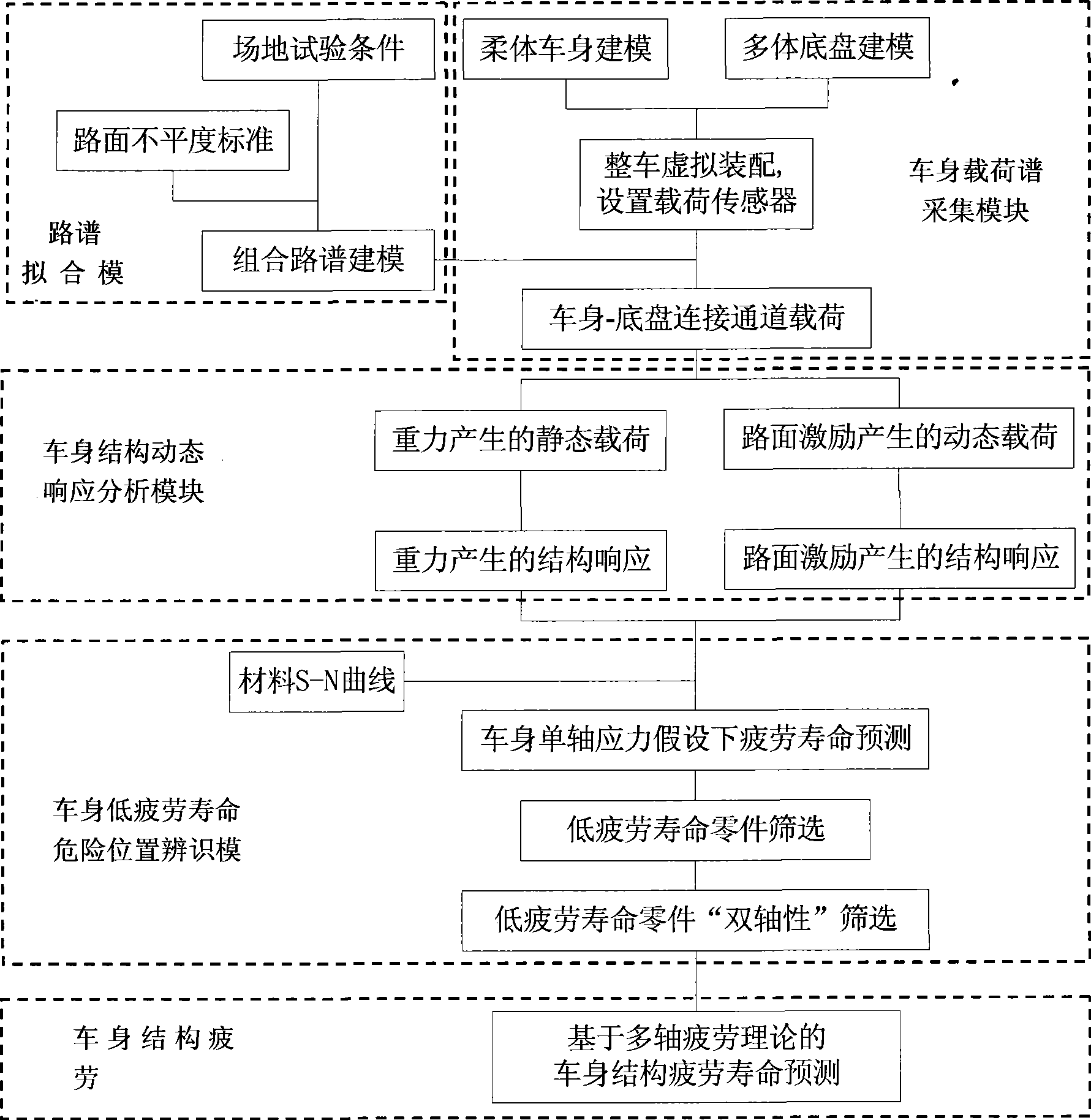

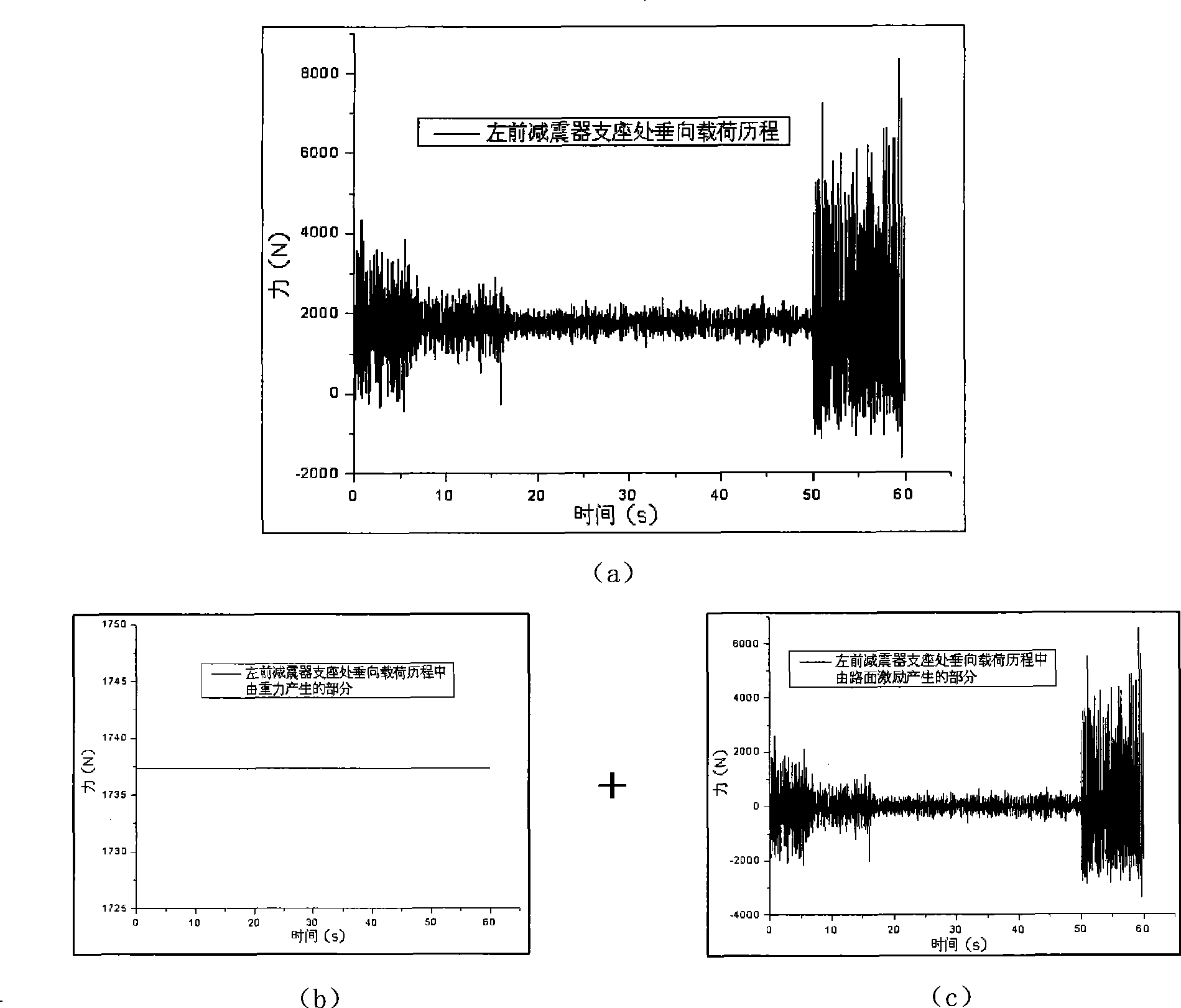

[0023] Such as figure 1 As shown, this embodiment includes: a road spectrum fitting module, a vehicle body load spectrum acquisition module, a vehicle body structure dynamic response analysis module, a vehicle body low fatigue life dangerous position identification module, and a vehicle body structure fatigue life prediction module, wherein:

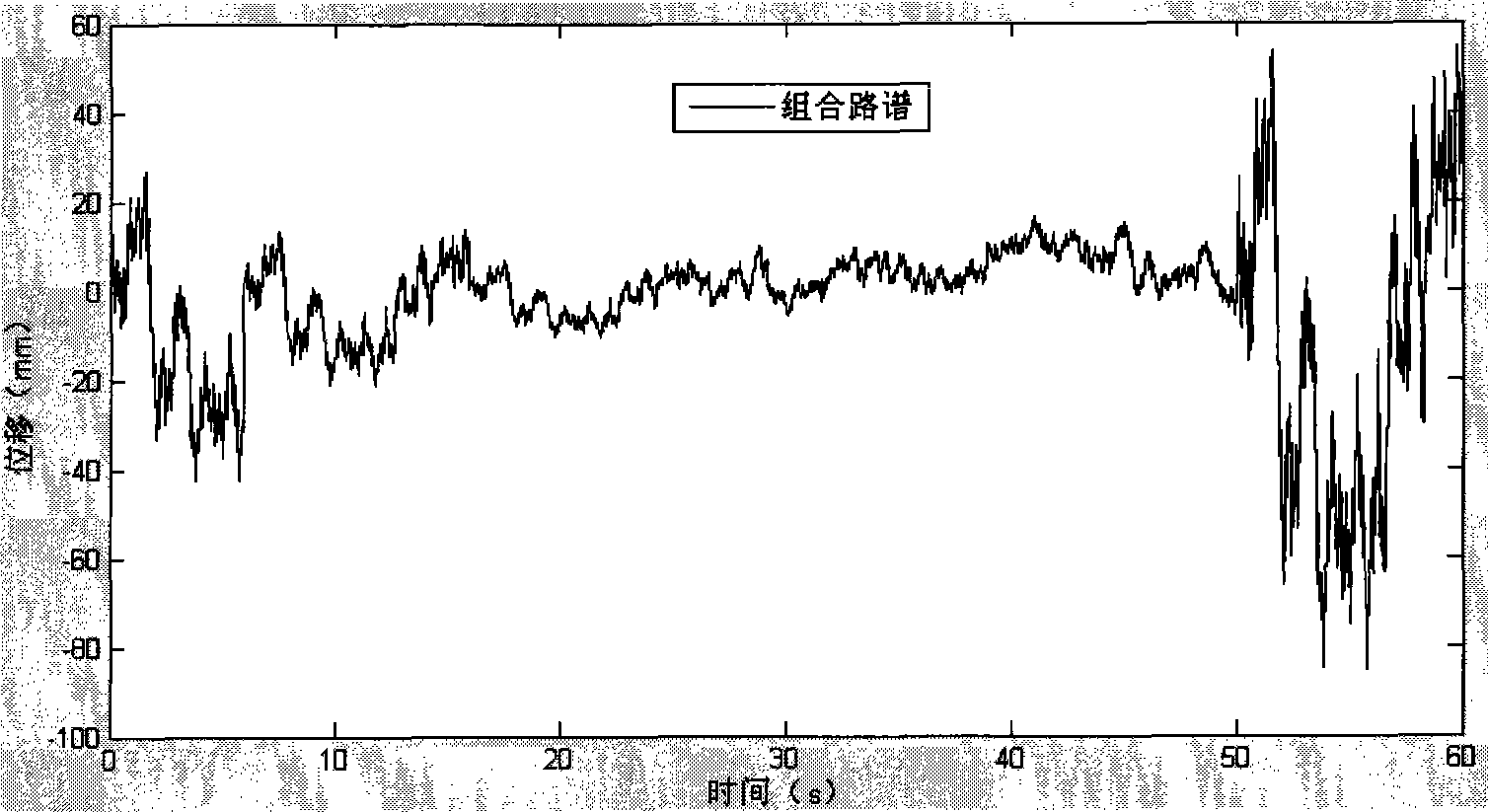

[0024] The road spectrum fitting module establishes road spectra suitable for different levels of roads according to the characteristic that the speed power spectrum of the same level of road surface is constant in the frequency domain and the national st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com