Lens coating jig and lens coating method

A technology of lenses and fixtures, applied in optics, instruments, optical components, etc., can solve problems such as inaccurate lens coating positions, affecting the imaging quality of optical products, reducing the yield rate of optical products, etc., and achieve good coating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The lens coating fixture and the lens coating method of the technical solution will be further described in detail below in conjunction with the accompanying drawings.

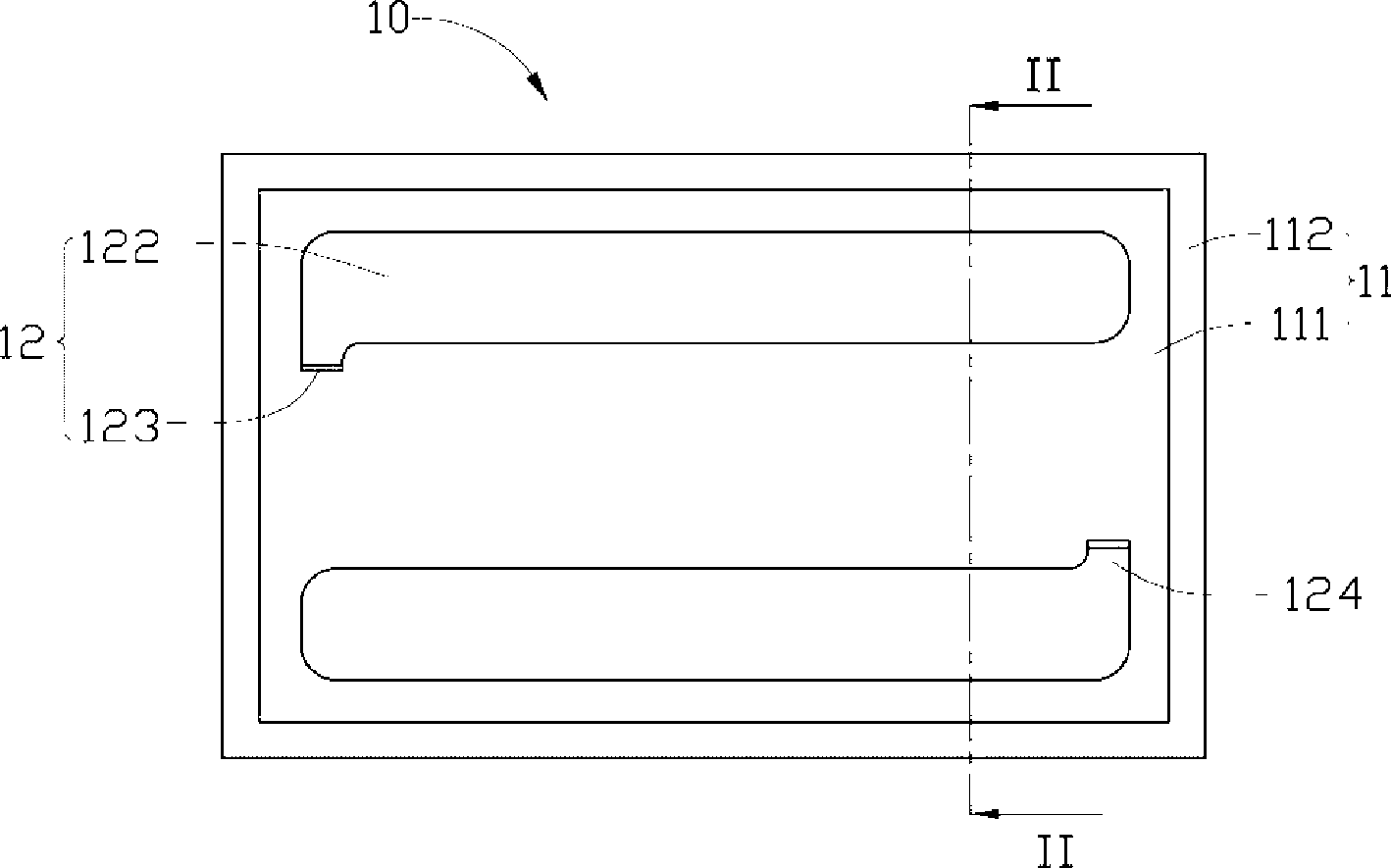

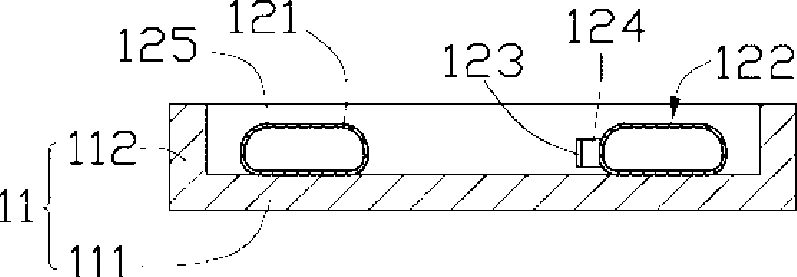

[0021] Please also refer to figure 1 and figure 2 The lens coating jig 10 provided by the first embodiment of the technical solution includes a frame body 11 and two holders 12 . The frame body 11 is composed of a bottom wall 111 and a side wall 112 , and the frame body 11 is used to support two holders 12 . The two holders 12 are placed oppositely in the frame body 11 and contact the bottom wall 111 , and the two holders 12 are used to cooperate and hold the lens.

[0022] Each holder 12 includes a capsule 122 surrounded by an elastic wall 121 and a sealing body 123 . The capsule body 122 is a strip-shaped hollow object having at least one opening 124 and an inner cavity 125 . The inner cavity 125 is used to accommodate fluid, and the at least one opening 124 is a channel for filling the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com