Apparatus for bobbin removal

A technology of reel and conveying device, which is applied in the direction of transportation and packaging, conveying filamentous materials, and thin material processing, etc. It can solve the problems of increasing position requirements and large distance between winding machines, etc., and achieves short interruption time and realizes interruption the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

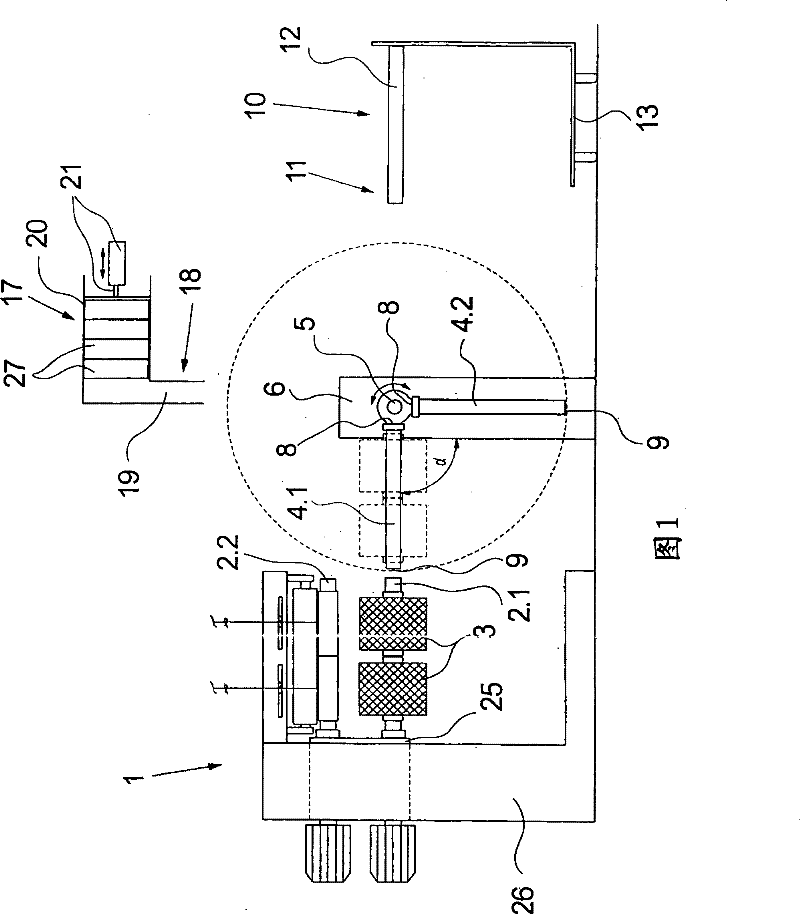

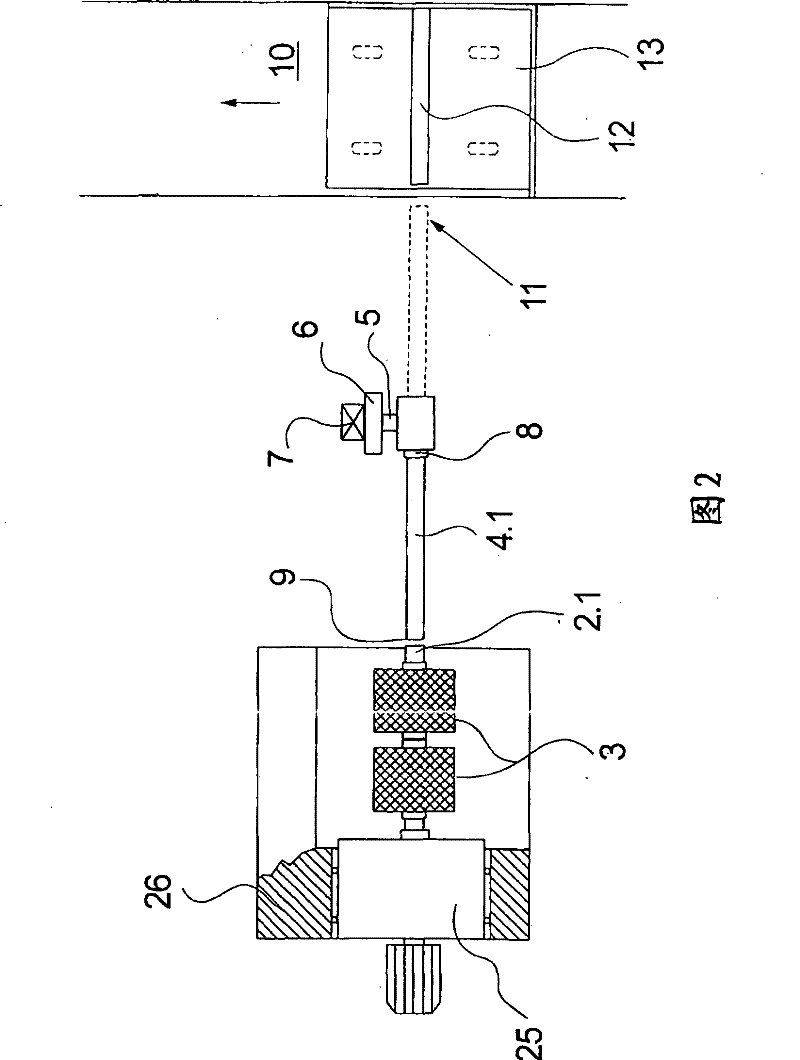

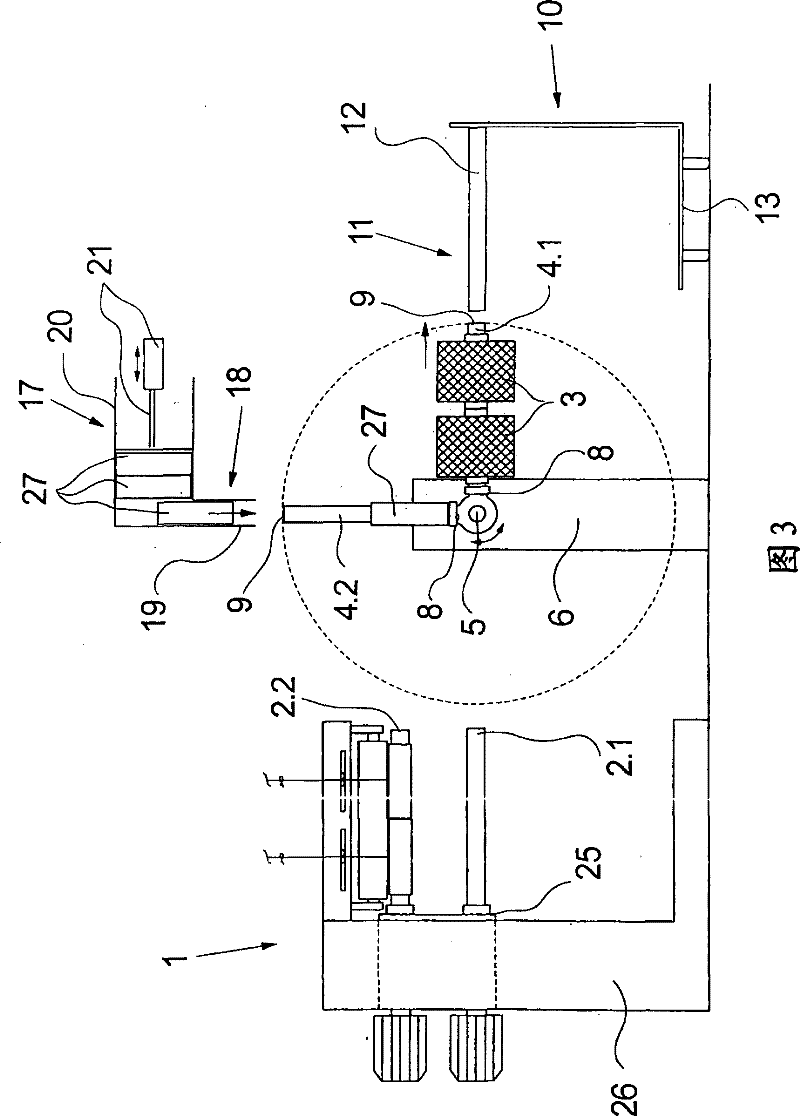

[0031] figure 1 and 2 A first embodiment of the device of the invention is shown in several views. figure 1 A side view of this embodiment is shown in the figure 2 Its top view is shown in . As long as one of the two figures is not explicitly referenced, the following description applies to both figures.

[0032] The device according to the invention has pivoting arms 4.1 and 4.2 which each have a fixed end 8 and a free sleeve end 9. The swivel arms 4.1 and 4.2 are connected by their fixed ends 8 to a swivel shaft 5. The shaft 5 is positioned horizontally and is mounted rotatably on a support 6 . In this exemplary embodiment, the rotary shaft is supported in a cantilevered manner, wherein the rotary arms 4 . 1 and 4 . The rotary shaft 5 is connected at the opposite end to a rotary drive 7, by means of which the rotary shaft 5 can be rotated together with the rotary arms 4.1 and 4.2 in clockwise and counterclockwise directions. The swivel arms 4.1 and 4.2 now move in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com