Wet etching apparatus and method

A technology of wet etching and etching solution, which is applied in the field of wet etching equipment and wet etching process, and can solve problems affecting wafer quality and residual etching solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

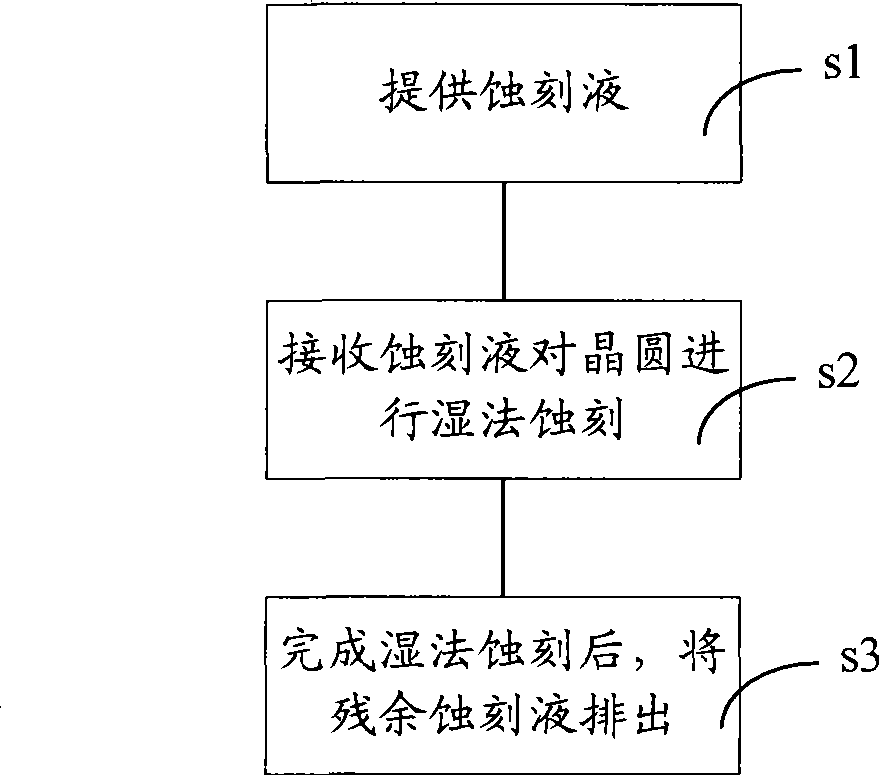

[0031] The wet etching device and method of the present invention discharges the residual etching solution when the wet etching is completed, so as to prevent the residual etching solution from dropping on the wafer due to gravity.

[0032] The wet etching device and method of the present invention are described in detail through preferred embodiments, so as to make the wet etching method and device of the present invention more clear.

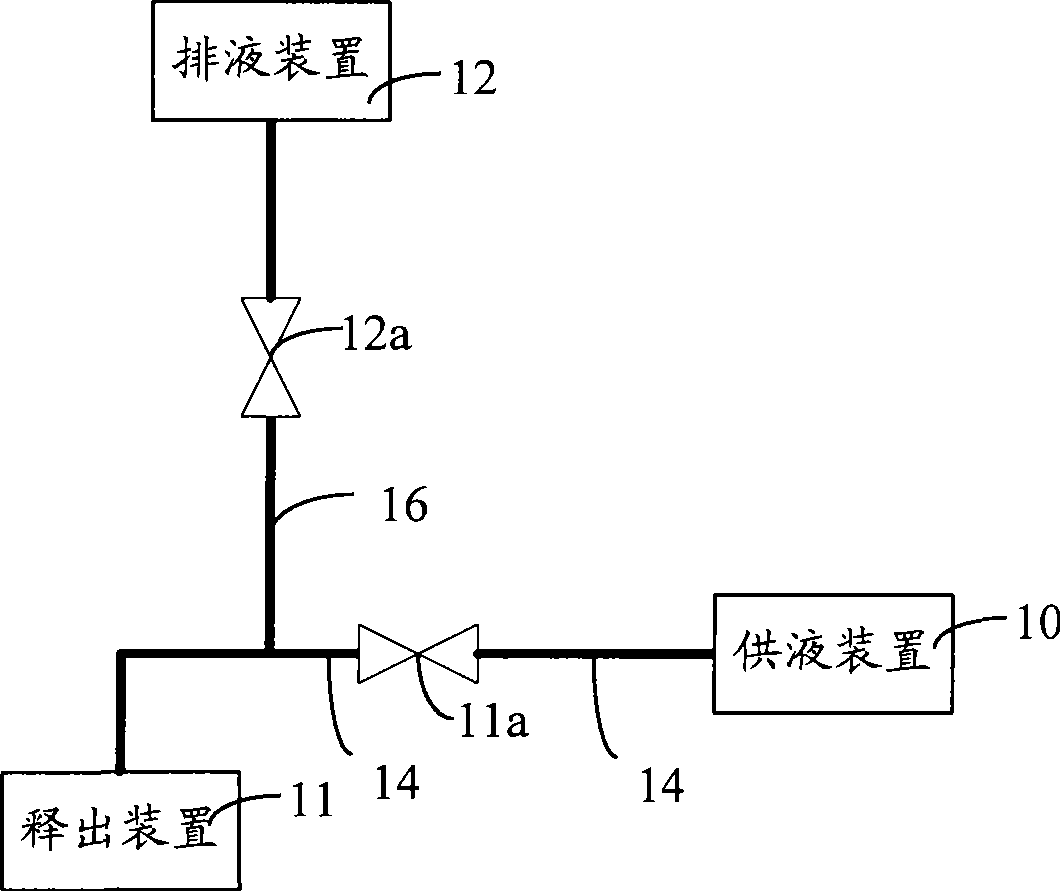

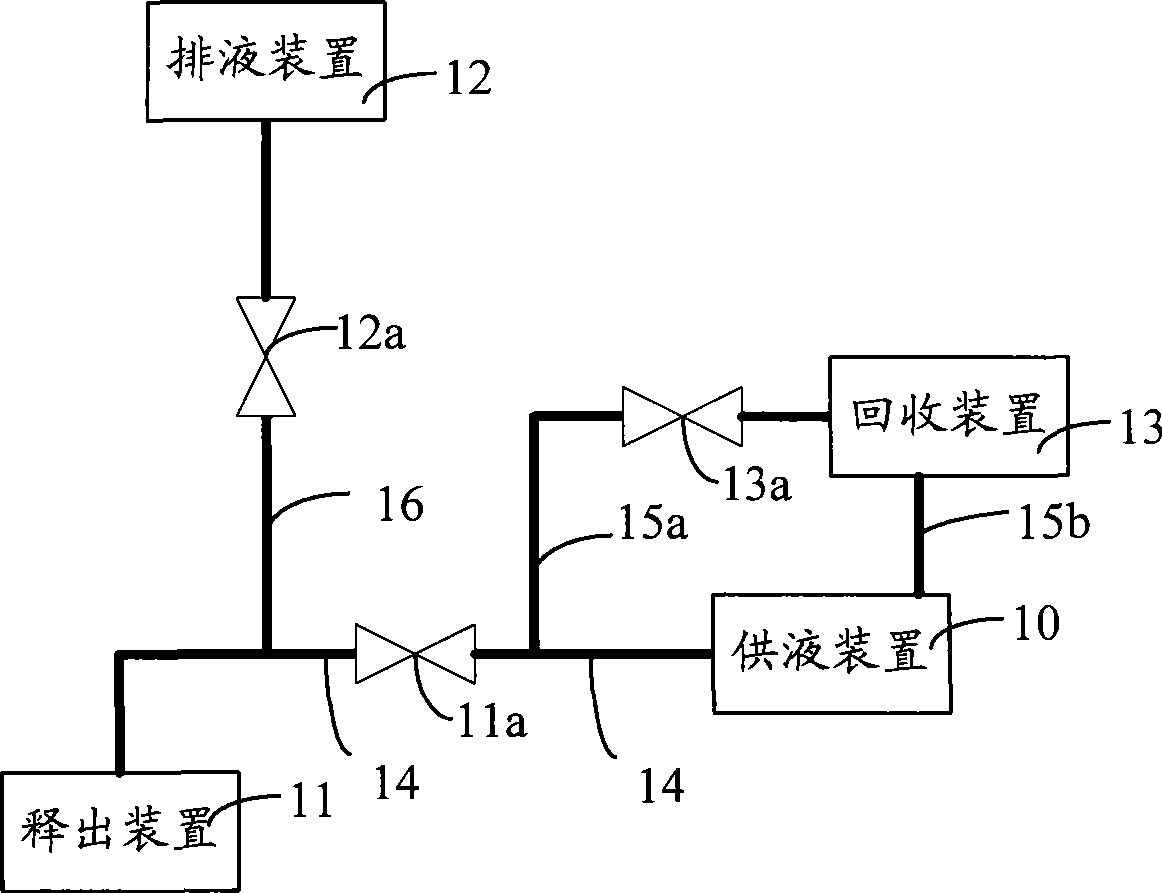

[0033] refer to figure 1 As shown, the wet etching device as an embodiment of the present invention includes,

[0034] A liquid supply device 10 for supplying etching liquid;

[0035] Connected to the liquid supply device 10, a transmission pipeline 14 for transporting etching liquid;

[0036] Connected to the transfer pipe 14, used to spray the etchant transported by the transfer pipe 14 on the surface of the wafer, and perform a release device 11 for wet etching;

[0037] Connected with the transfer pipeline 14, a drain pipeline 16 for tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com