Direct freezing double-system double door refrigerator with freezing chamber at upper part

A dual-system, double-door technology, which is applied in household refrigerators, coolers, household refrigeration devices, etc., can solve the problems of refrigerated frosting, the inability to control the temperature independently, and high energy consumption, so as to prevent the back of the refrigerator Frosting, solving uneven refrigeration temperature, and preventing frosting on the back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

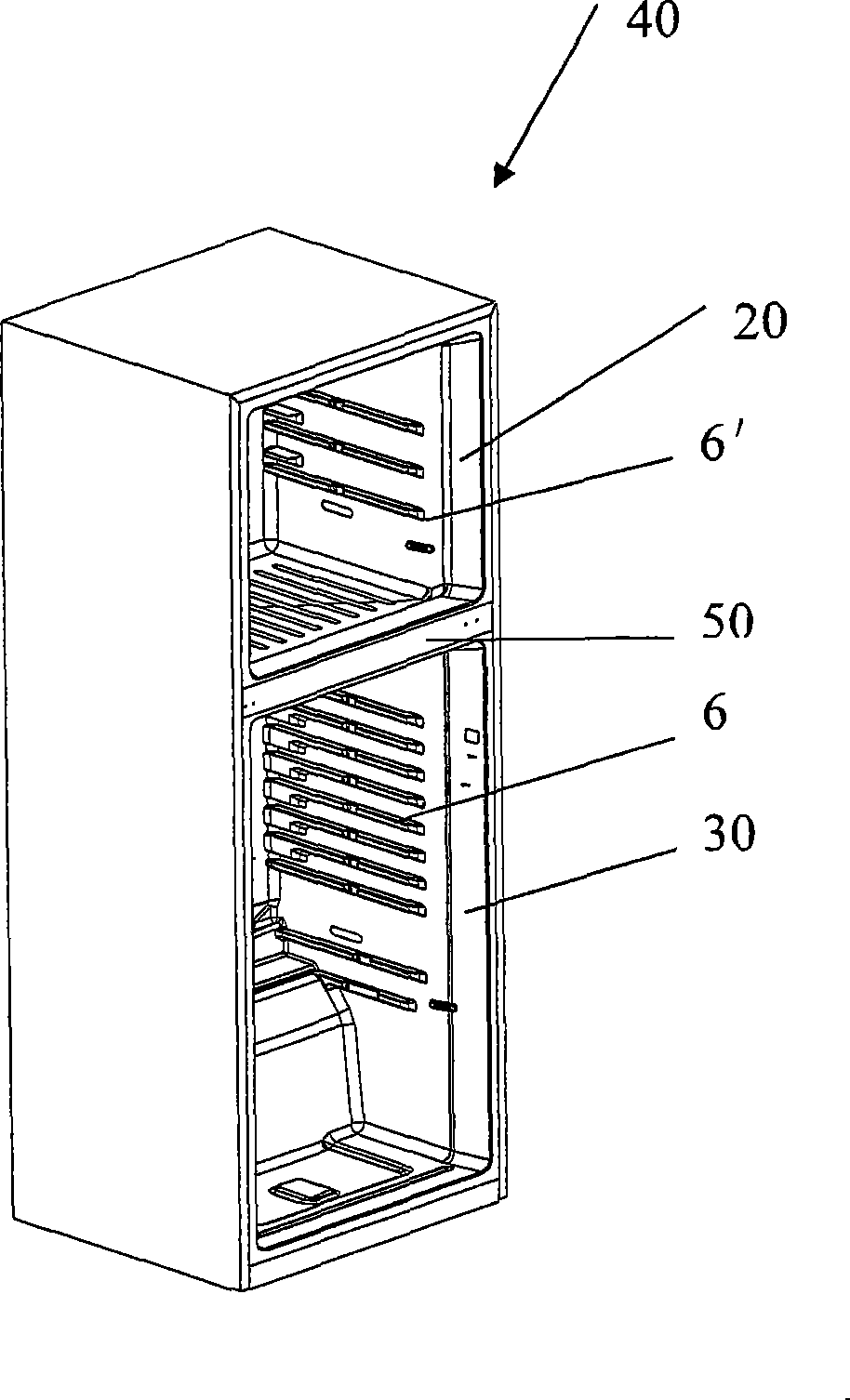

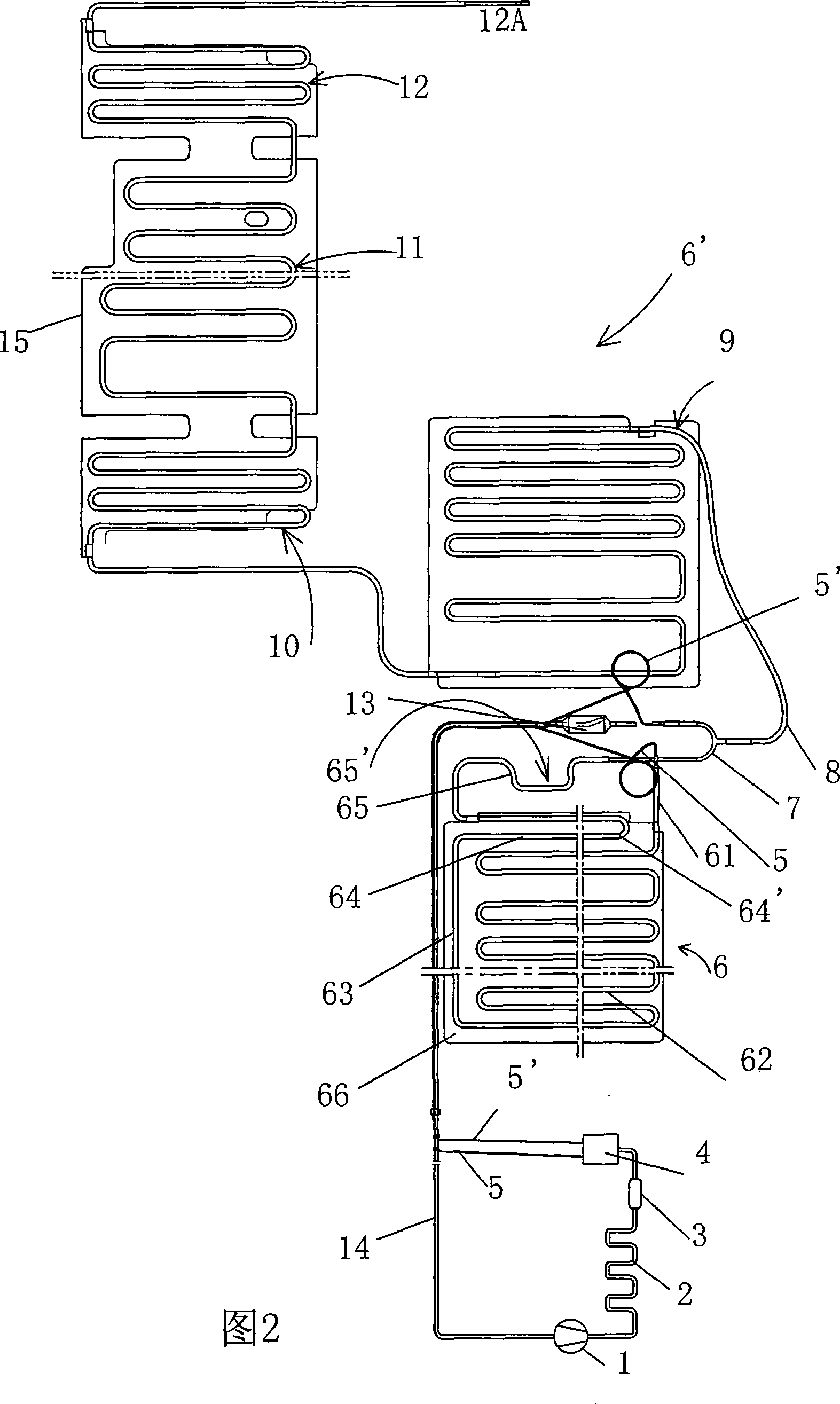

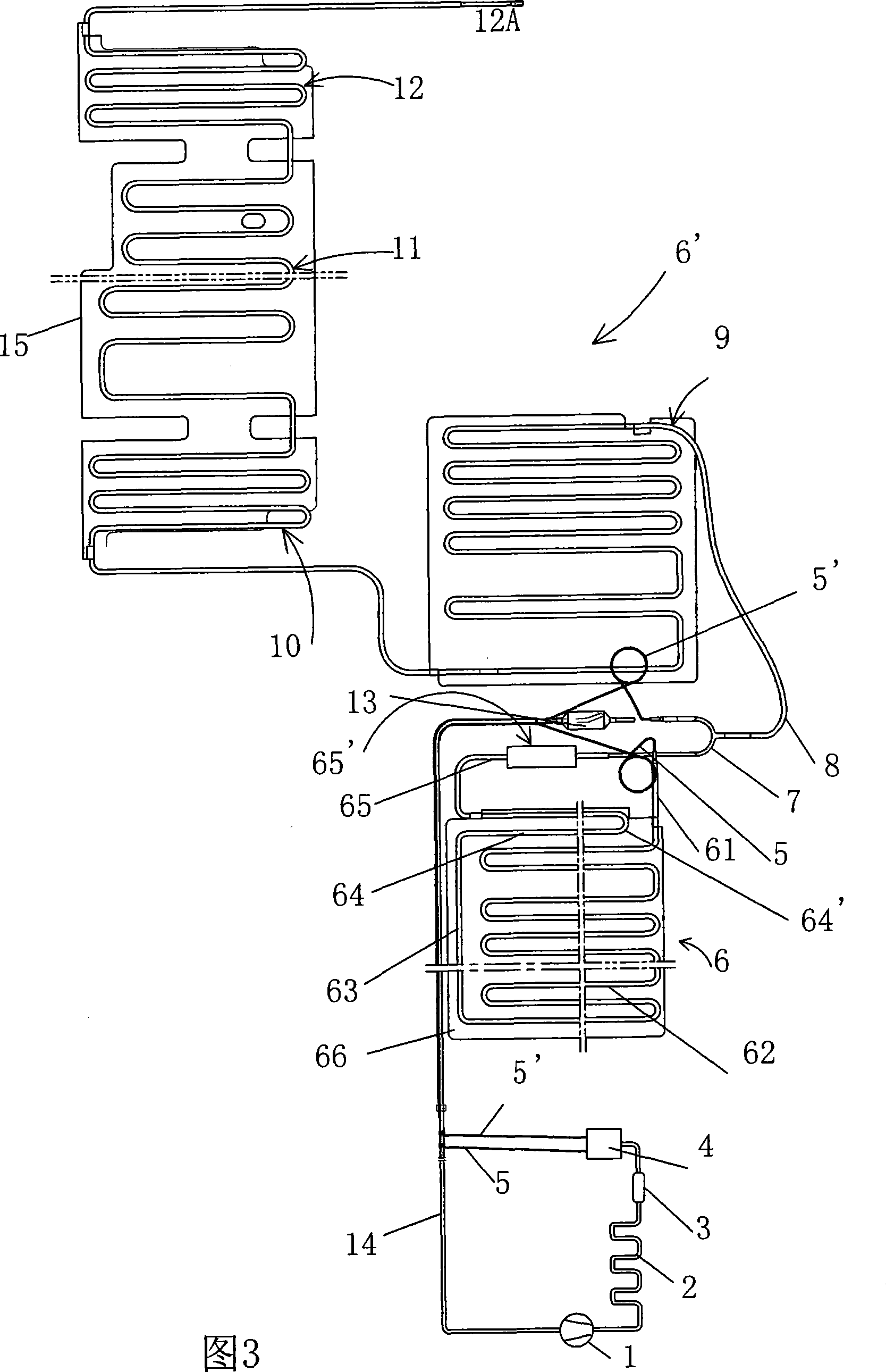

[0032] Such as figure 1 , shown in Fig. 2 and Fig. 3, a kind of direct cooling double-system double-door refrigerator of the present invention is frozen on top, and its structure comprises a box body 40 that is divided into freezing chamber 20 and refrigerating chamber 30 by center beam 50, is respectively used for The refrigerating evaporator 6' and the refrigerating evaporator plate 15 thereof, the refrigerating evaporator 6 and the refrigerating evaporator plate 66 thereof of the freezing chamber 20 and the refrigerating chamber 30, and the compressor 1 arranged on the casing 40, and the compressor 1 A condenser 2, a dry filter 3, and a three-way solenoid valve 4 connected in sequence by an exhaust pipe, the freezing chamber 20 is arranged on the upper part of the casing 40, the refrigerating chamber 30 is located on the lower part of the casing 40, and the freezing evaporator The dual system of 6' and refrigeration evaporator 6 is a direct cooling structure. The main feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com