Screw sieving machine

A screening machine and screw technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low efficiency, high price, difficult promotion, etc., and achieve the effect of accurate detection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate those skilled in the art to understand, the present invention will be described in further detail below in conjunction with embodiment:

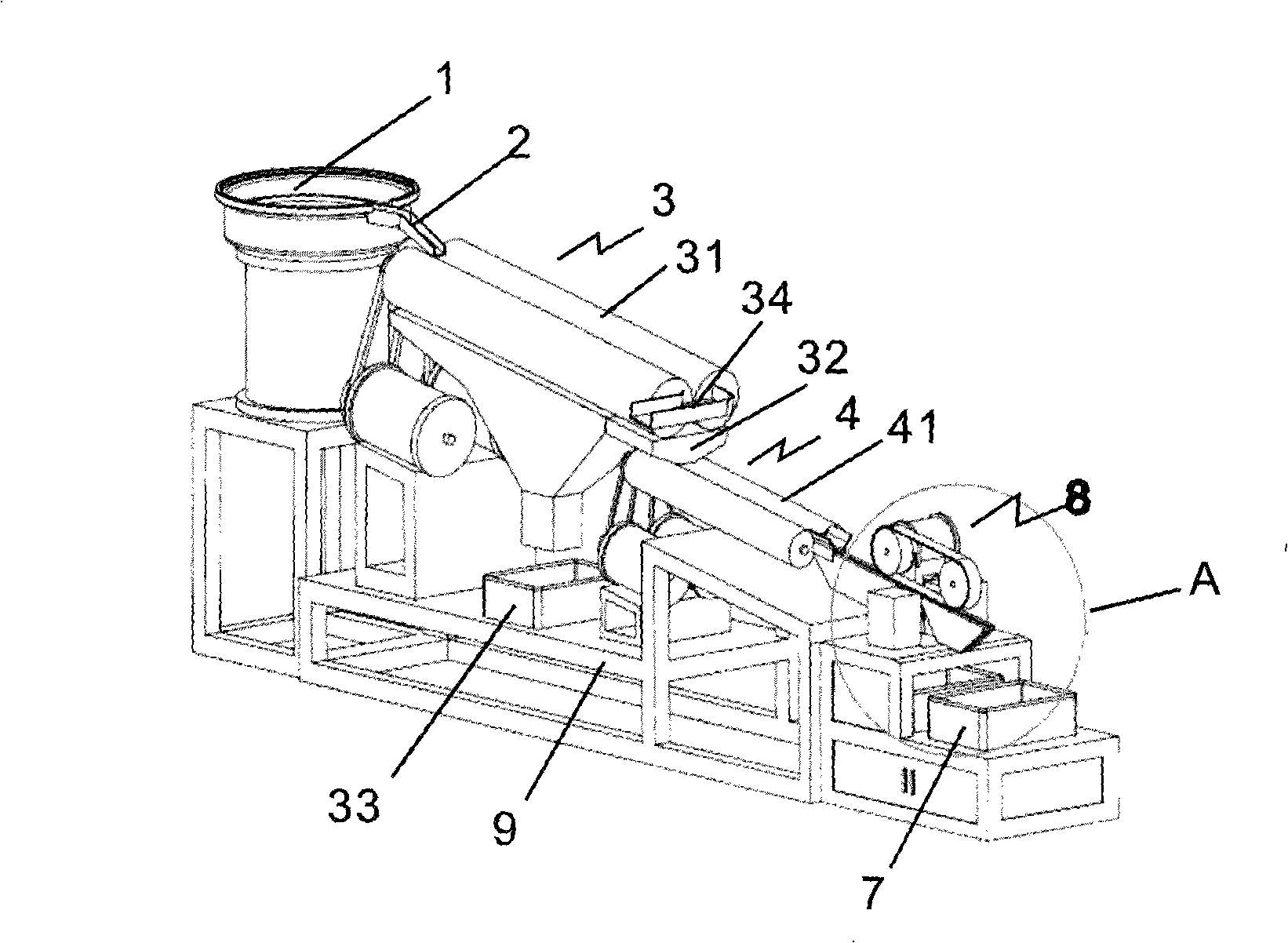

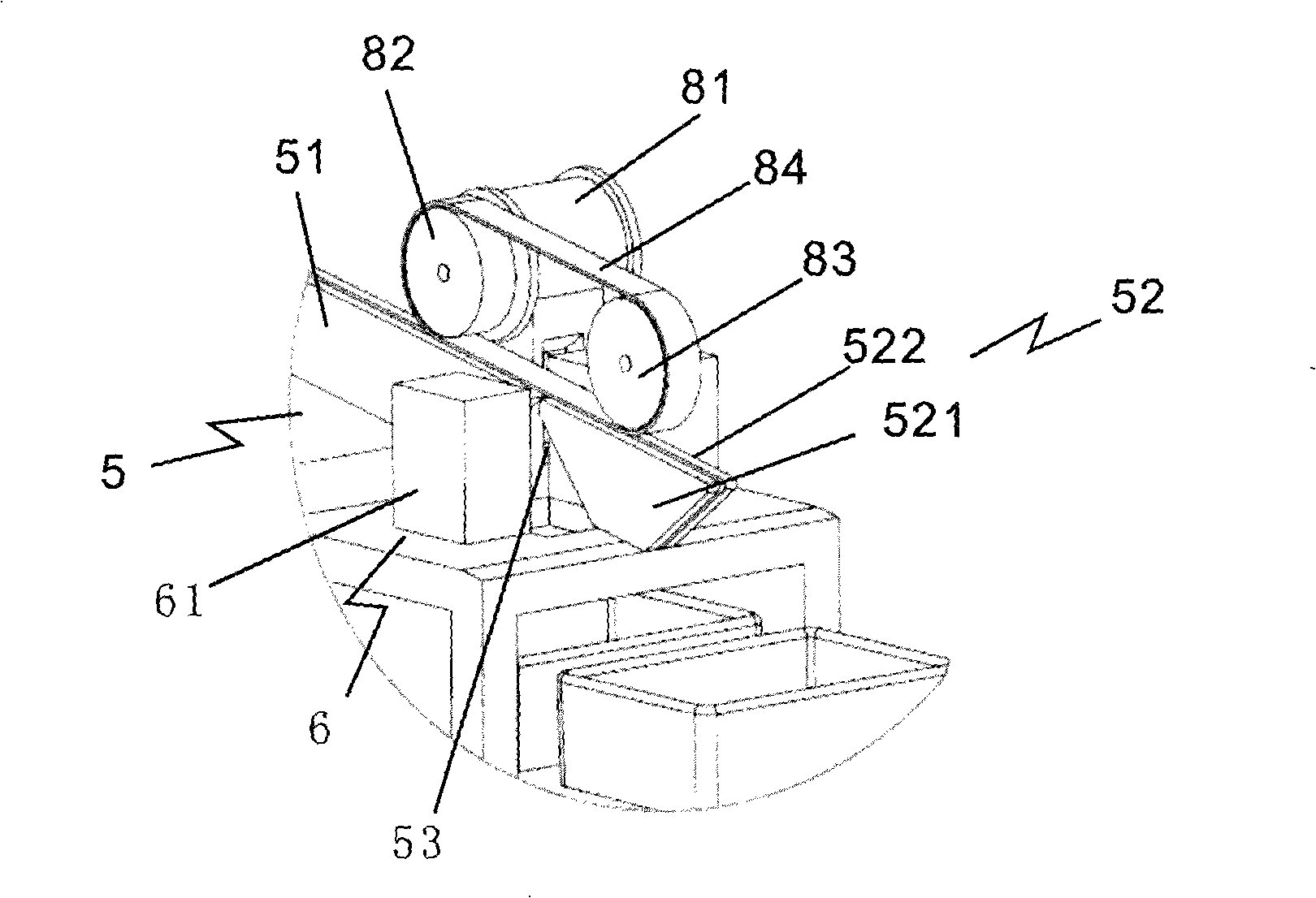

[0014] as attached figure 1 , 2 As shown, the screening machine disclosed in this embodiment mainly includes a vibration plate 1, a guide groove 2 installed on the outlet of the vibration plate 1, and a screw head screening assembly 3 and a screw alignment assembly 4 installed behind the guide groove 2 in turn. , chute assembly 5, screw length detection assembly 6 and qualified product box 7. Among them, the vibration plate 1 is used to vibrate irregularly placed screws from the guide groove 2 in sequence, the screw head screening component 3 is used to reject products with unqualified screw and nut sizes, and the screw alignment component 4 is used to sequentially separate the screws Placed on the chute assembly 5, the screw length detection assembly 6 is used to detect the length of the screw, and the length...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap