Double-working medium refrigeration experiment system used for turbine blade of gas turbine

A technology of turbine blades and gas turbines, which is applied in the direction of gas turbine engine testing, jet engine testing, machine/structural component testing, etc., and can solve problems such as data reliability and accuracy cannot be guaranteed, steam cooling cannot be realized, and duration is short, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

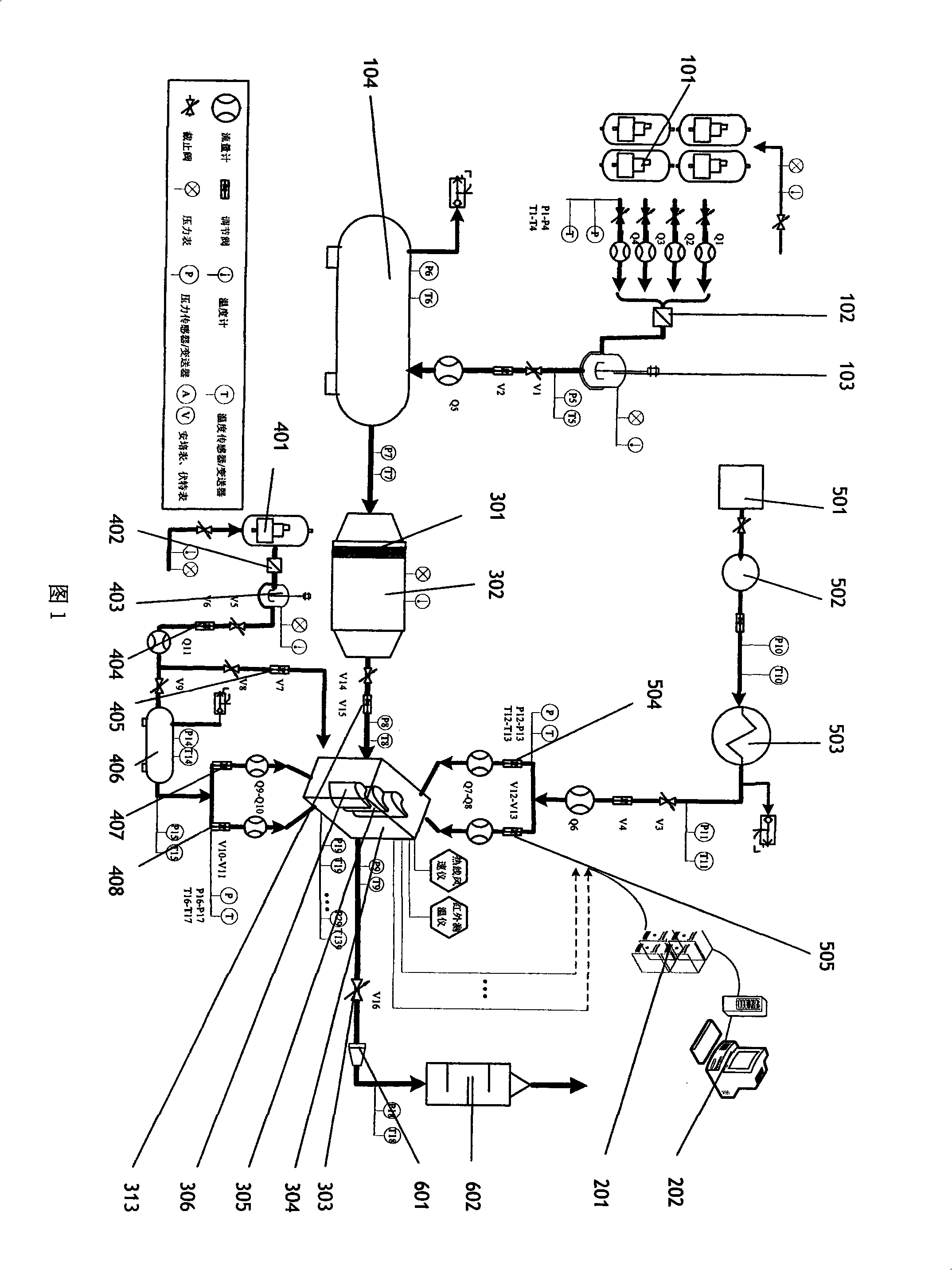

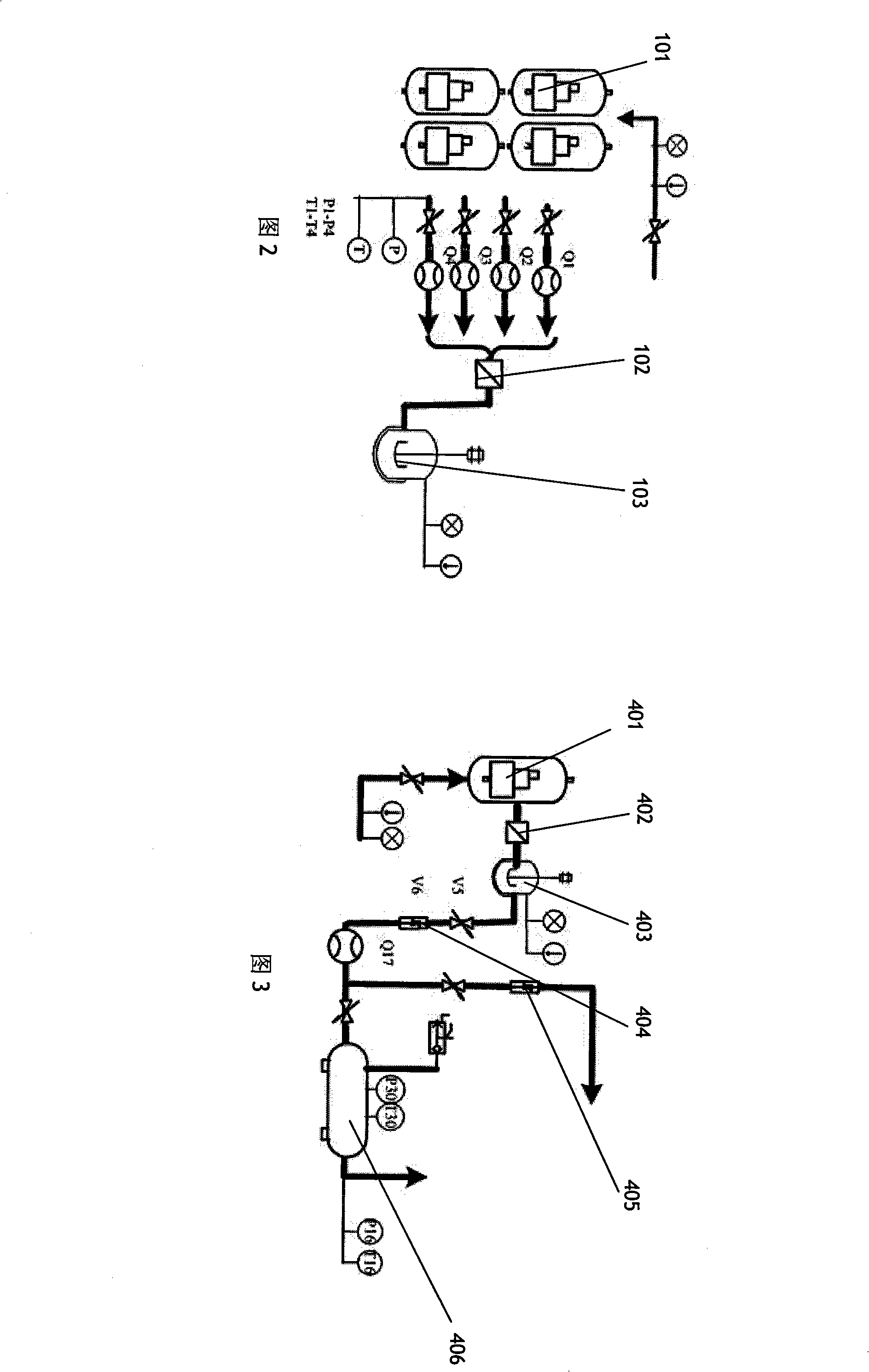

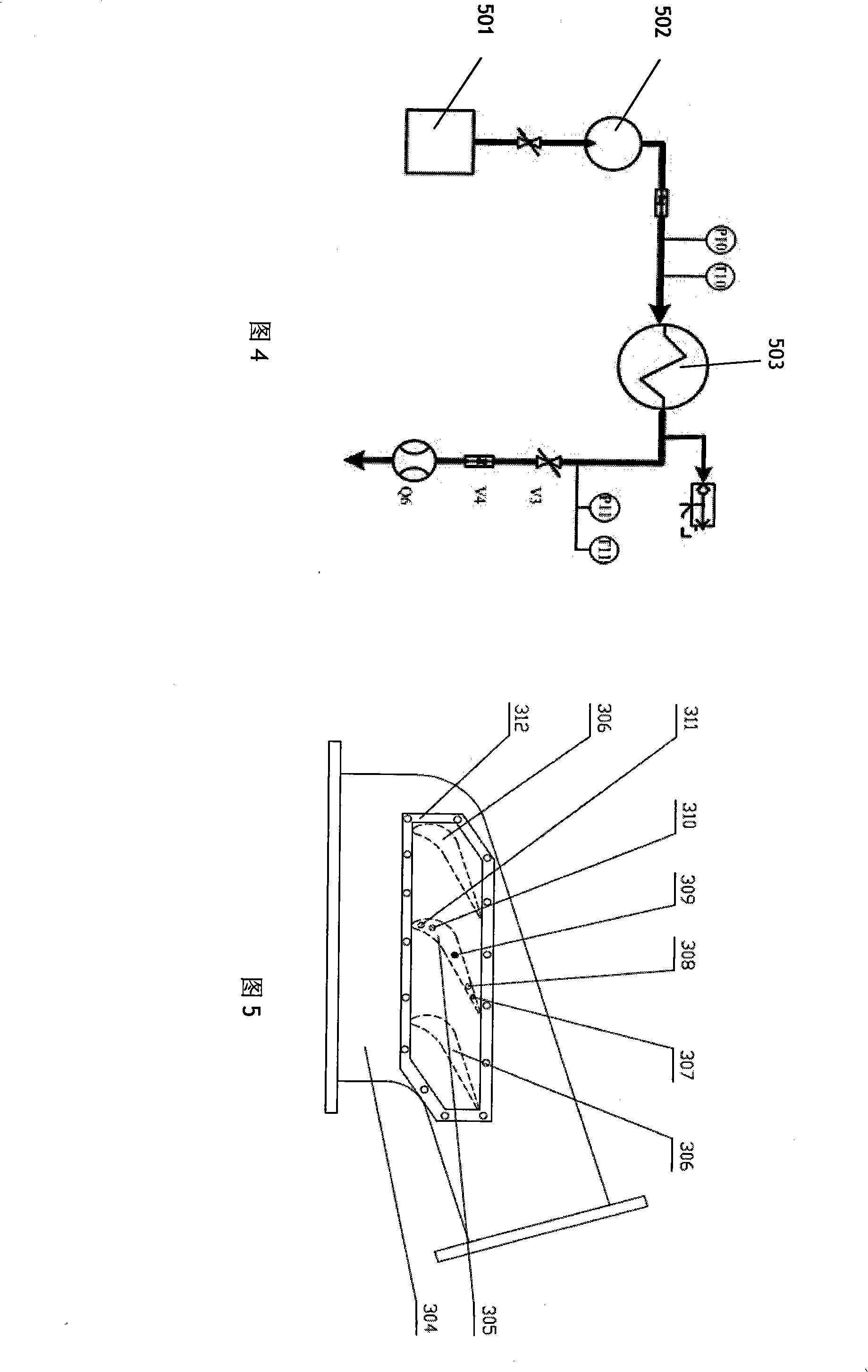

[0026] The working principle and operation method of the experimental system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Referring to Figure 1, the experimental system mainly includes the following parts: ① Mainstream air source unit; ② Experimental section unit; ③ Cooling air unit; ④ Cooling steam unit; ⑤ Data acquisition unit; ⑥ Control unit; ⑦ Exhaust unit.

[0028] The experimental section unit mainly includes an air intake rectifying device 302 and an experimental section 304 . The air intake rectifying device 302 is equipped with a honeycomb 301 and a damping net. The air intake rectification device is equipped with a honeycomb 301 and a damping net, so that the quality of the mainstream air flow passing through the rectification device is better, and a turbulent grid is also installed at the entrance of the test section 304 to adjust the gas turbulence entering the test section degree is within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com