Vehicle paint sagging experiment board and test method

A test board and anti-sag technology, applied in the direction of material inspection products, etc., can solve problems such as the lack of targeted testing methods, and achieve the effects of low cost, good operability, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The example is the production of a test board for anti-sagging performance.

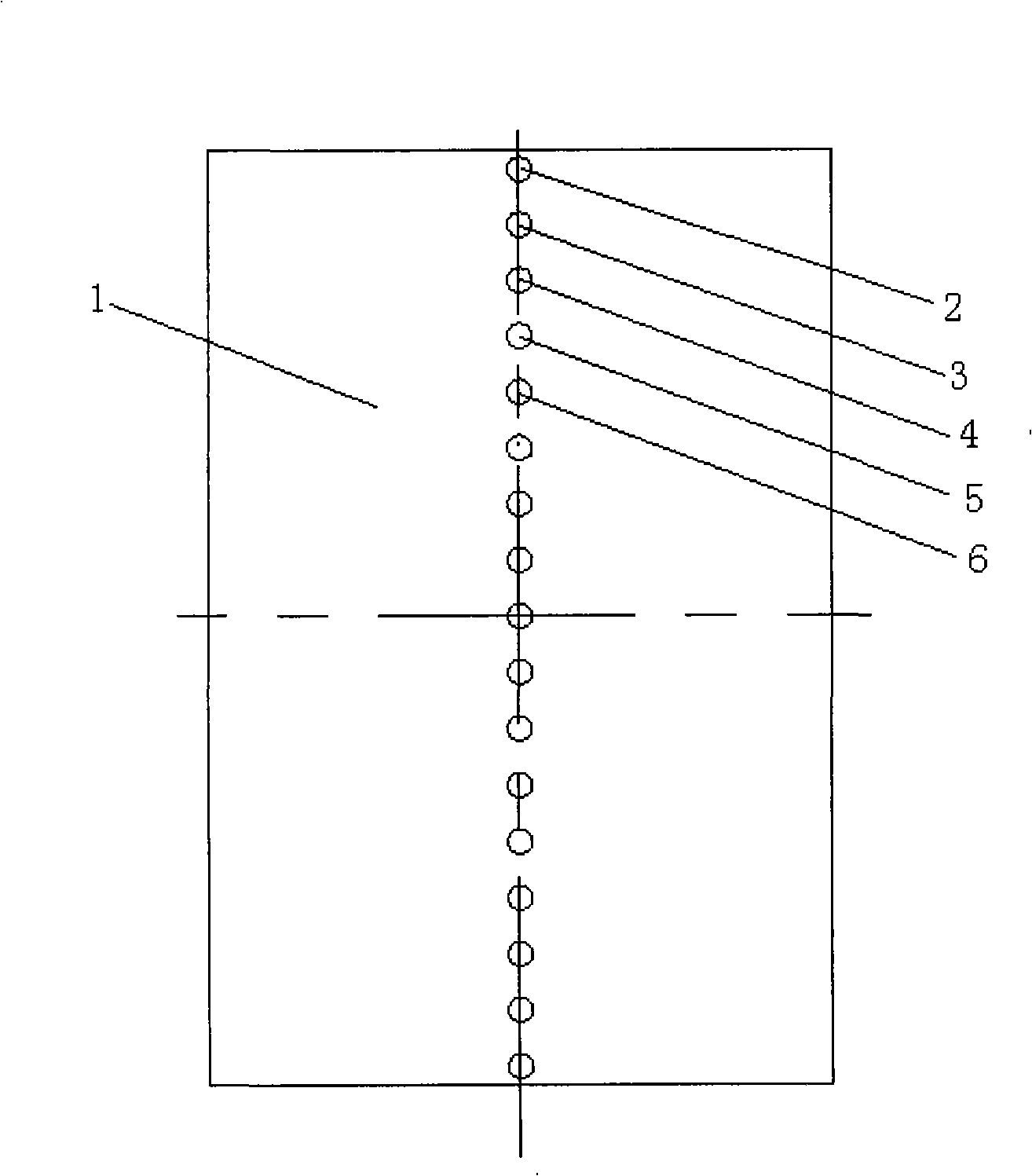

[0020] Such as figure 1 As shown, an automobile paint sag resistance test board 1 is the same as the body steel plate, with a smooth surface and electrophoresis treatment; there are a set of holes with the same spacing and the same diameter from the top to the bottom of the board, such as the first hole 2, the second hole Two holes 3, third holes 4, fourth holes 5, and fifth holes 6.

[0021] The size design of the hole diameter and hole distance is determined according to the allowable value of the length of the sag (can be modified). The hole diameter is 8-10 mm, and the hole pitch is 8-20 mm. Preferably, the hole diameter is 8 mm, and the hole pitch is preferably 18 mm. Requirements: The edge of the hole is smooth and flat, without burrs.

[0022] A row of small holes in the middle of the board from top to bottom are used to simulate the holes in the front side lights, handles, etc. of the car,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com