Touch control type substrates, colored optical filtering substrates and touch control type LCD

A technology of color filter substrate and color filter layer, which is applied in the direction of static indicators, optics, instruments, etc., can solve the problems of reducing the transmission speed of sensing signals, etc., and achieve the problem of improving the sheet resistance value too high and the light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

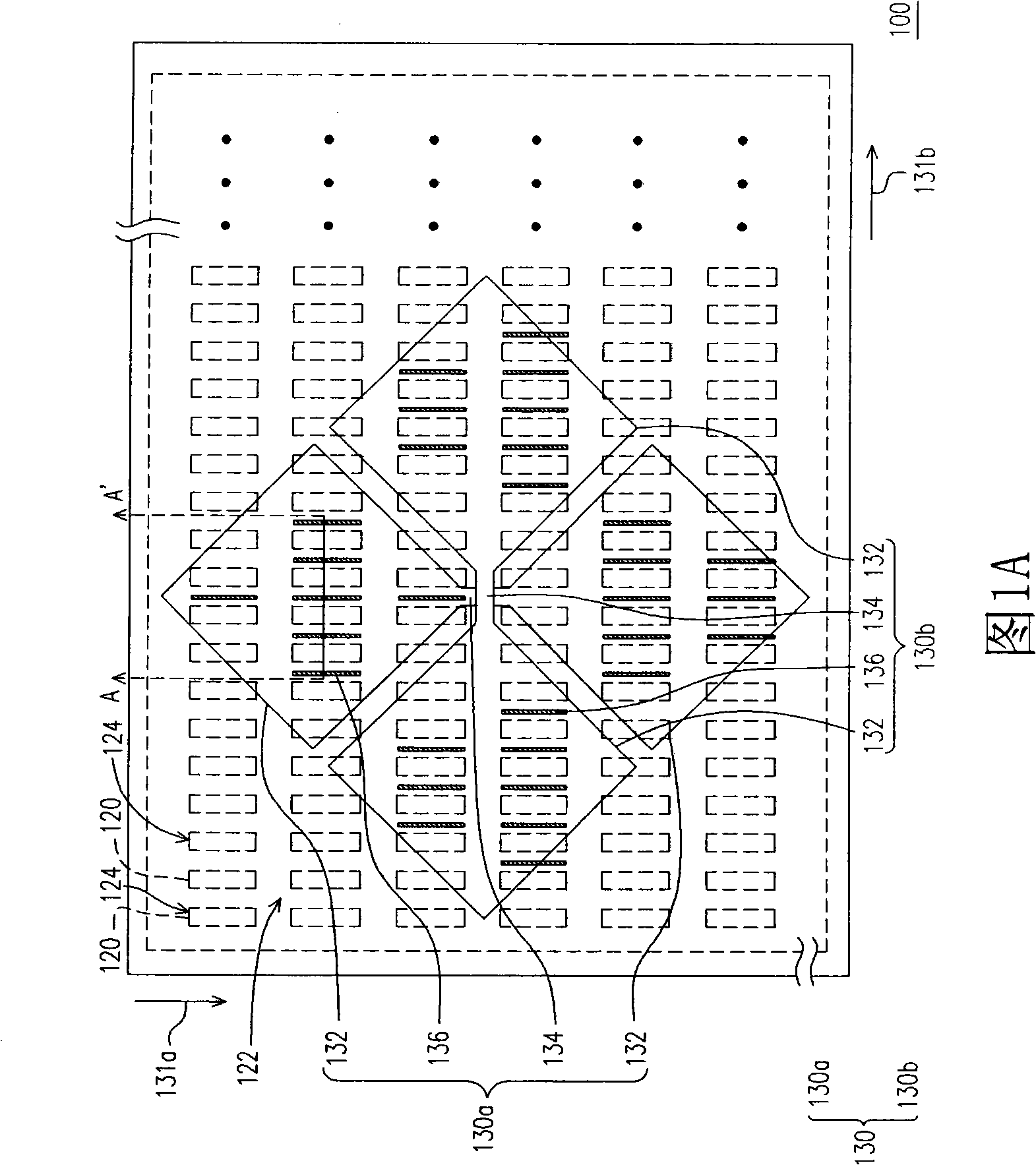

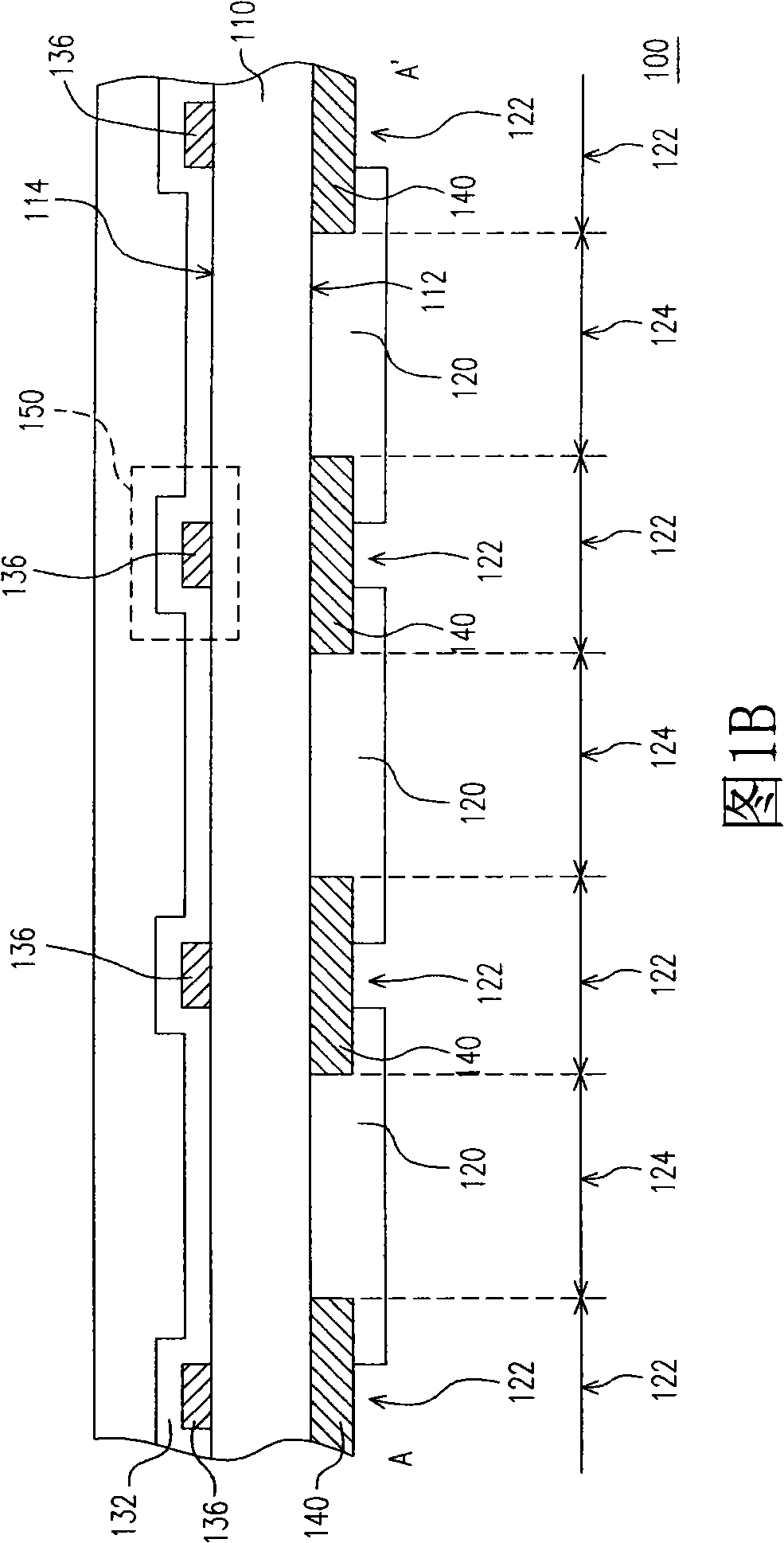

[0059]FIG. 1A shows a partial top view of a color filter substrate according to an embodiment of the present invention, and FIG. 1B is a schematic cross-sectional view of the color filter substrate shown along line AA' in FIG. 1A , wherein the color filter substrate shown in FIG. 1A The dotted line area is a perspective view of the first surface of the color filter substrate. In addition, for the convenience of illustration, FIG. 1A mainly shows a schematic diagram of a display block, a patterned color filter layer, a separation area, and a sensing series, while omitting other parts. possible layers. Comparing FIG. 1A and FIG. 1B at the same time, it can be known that the color filter substrate 100 is a double-sided design structure of the touch-sensitive color filter substrate. The structure of the color filter substrate 100 will be described in detail below.

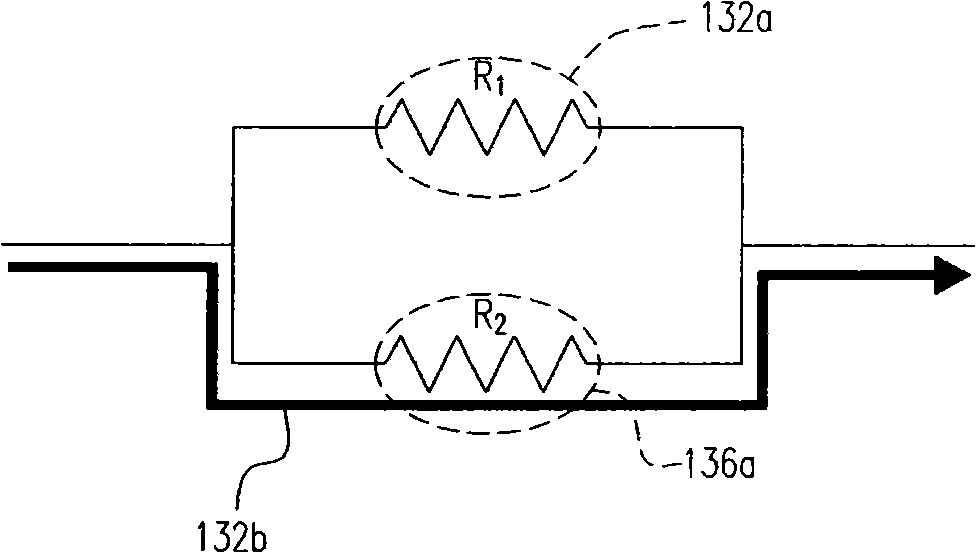

[0060] Please refer to FIG. 1A and FIG. 1B at the same time. The color filter substrate 100 of this embodiment inclu...

no. 2 example

[0088] The touch-sensitive substrate of this embodiment adopts a design concept similar to that of the above-mentioned color filter substrate, but the difference lies in that the touch-sensitive substrate of this embodiment is equipped with sensing series on the substrate, and the above-mentioned patterned color The filter layer is correspondingly arranged on the display area of the transistor array substrate. In other words, the touch-sensitive substrate of this embodiment can be the opposite substrate, and the touch-sensitive substrate mainly provides touch function. The connection relationship of each component of the touch-sensitive substrate will be described in detail below.

[0089] FIG. 5 is a partial top view of a touch-sensitive substrate according to the present invention. For convenience of description, FIG. 5 mainly shows the structure of the display block and the sensing series, while omitting other possible film layers. Please refer to FIG. 5 , the touch-sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com