Light emitting device and method for manufacturing the same

A light-emitting device and manufacturing method technology, applied in the direction of light-emitting materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of uneven content of phosphor 400 and uneven phosphor 400, and achieve small difference in light emission, and Improvement of pass rate and improvement of mass productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

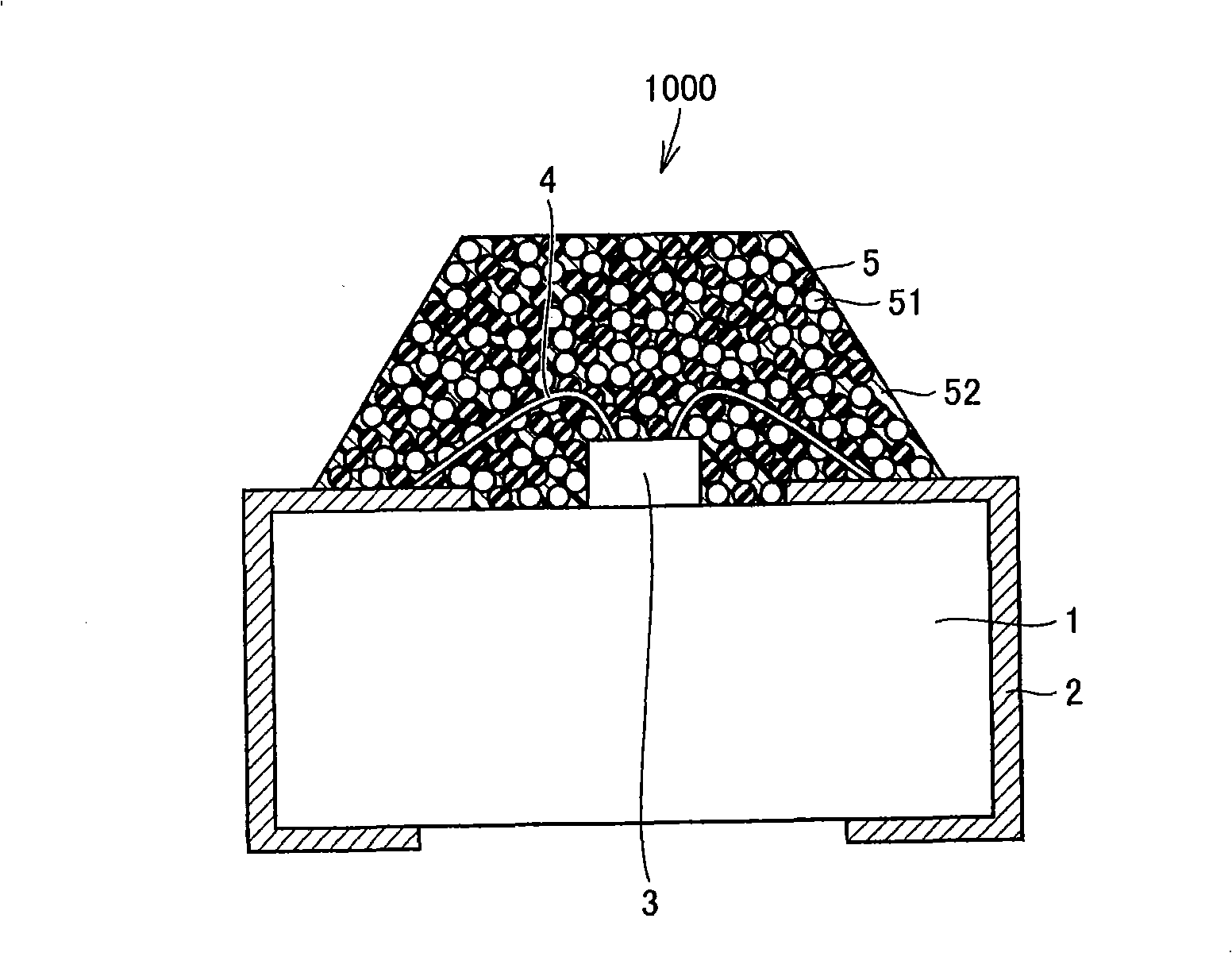

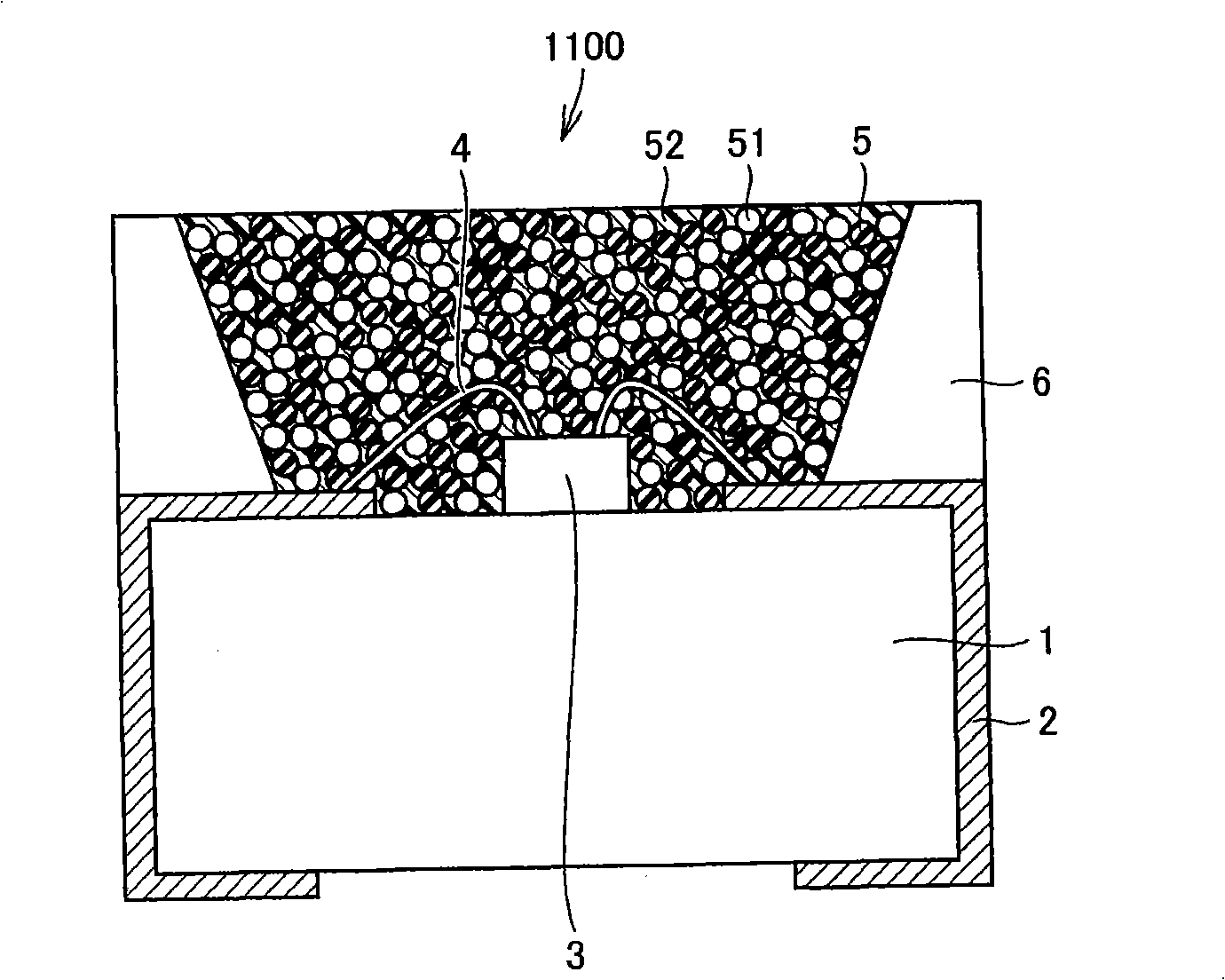

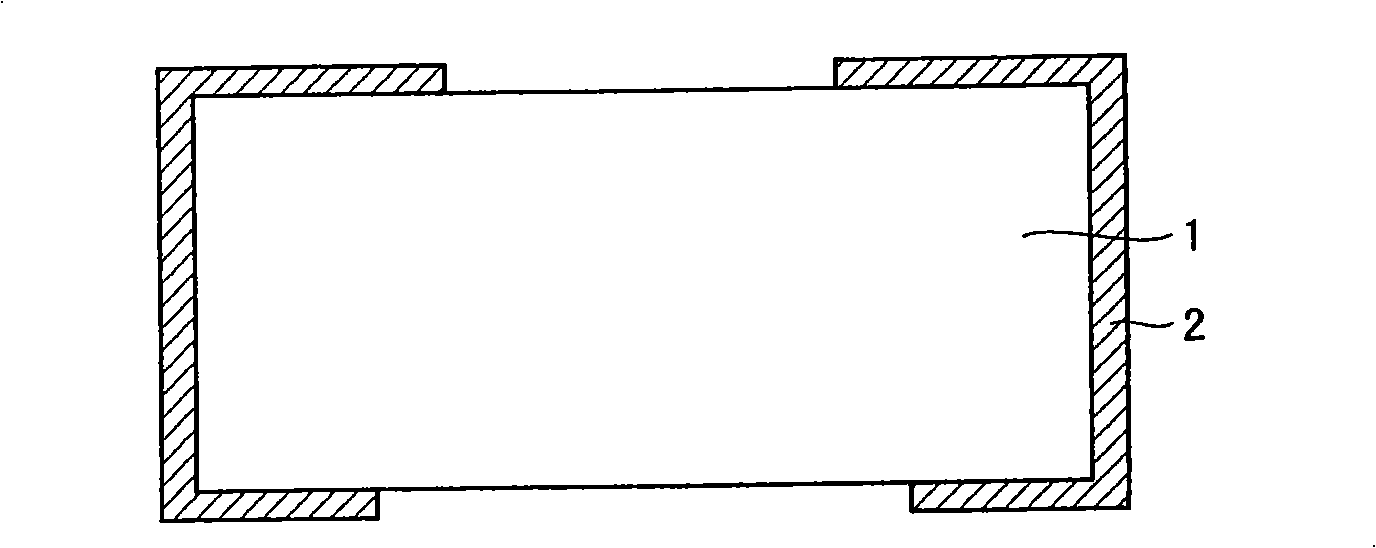

[0068] In the following, in the drawings of this application, the same reference numerals denote the same or corresponding parts. In addition, in order to clarify and simplify the drawings, dimensional relationships such as lengths, dimensions, and widths in the drawings are appropriately changed and do not represent actual dimensions.

[0069] In addition, in the following drawings of this application, description is made using "resin particles", but this is for convenience. Therefore, in the structure of the light-emitting device of the present invention, the portion belonging to the "resin particles" described below may be composed of only "resin particles", may be composed of "a mixture of resin particles and inorganic material particles", or may be composed of "Inorganic material particles". Among them, the material of the resin particles is resin, and the material of the inorganic material particles is an inorganic material, and the two materials are different.

[0070] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com