III-nitride semiconductor light emitting device

A technology of nitride semiconductors and light-emitting devices, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as difficult manufacturing, and achieve the effect of promoting current expansion and improving ESD characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

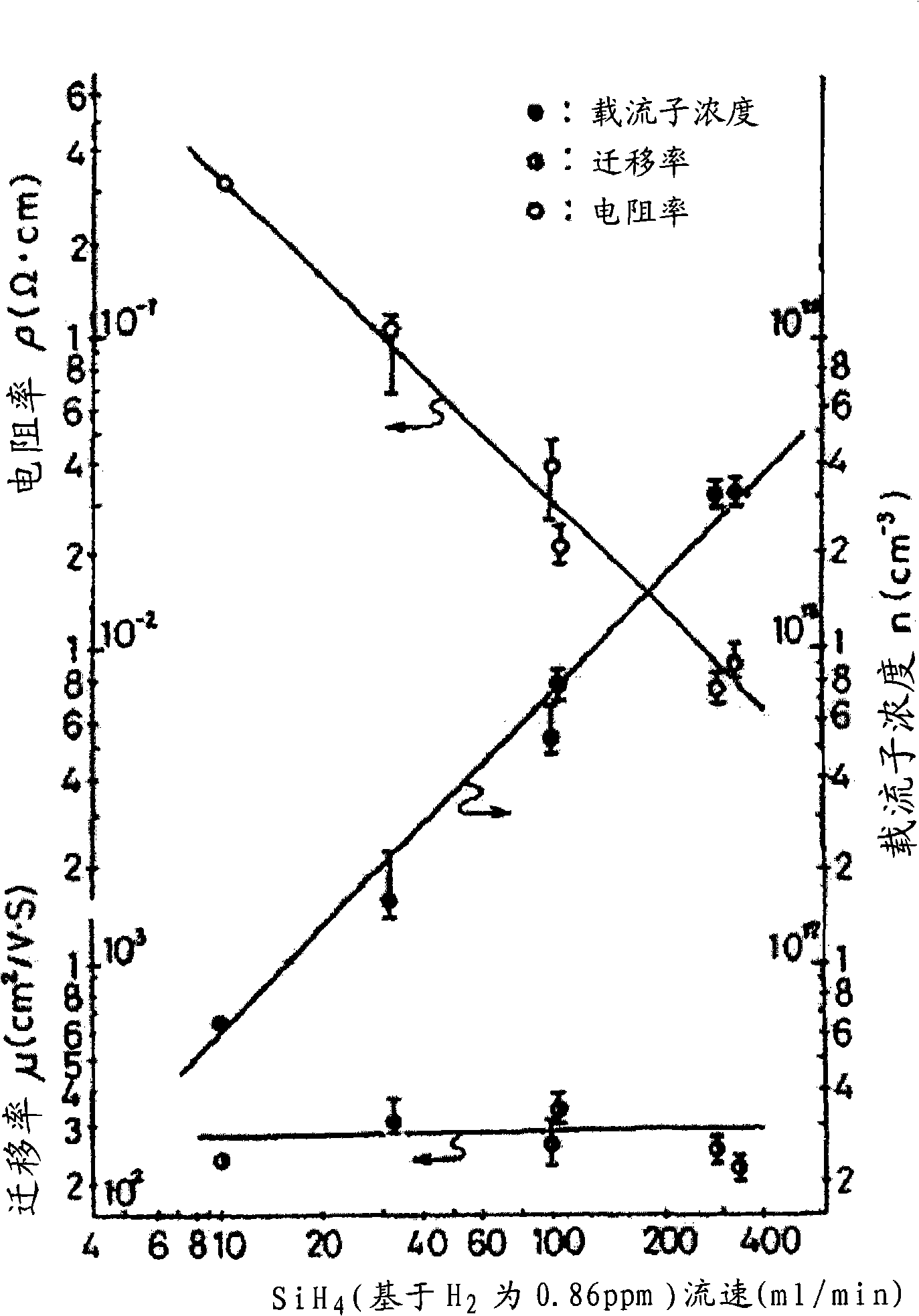

[0052] Figure 6 is a view describing an experimental example of the present invention, specifically, a surface micrograph (left side) showing a state in which 5×10 19 / cm 3 doping concentration (9.5sccm of DTBSi supplied as Si source) and thickness of the n-type GaN layer and having The thickness of the un-GaN layer (by adjusting the supply time of the Si source, for example, supplying the Si source for 15 seconds and stopping the supply for 25 seconds) to grow an n-type nitride semiconductor layer having a thickness of about 2 μm, and a surface showing the following state Microscopic photographs (right side): in which an n-type nitride semiconductor layer was grown under different conditions by supplying 9.0 sccm of DTBSi as a Si source. This experiment is used to study whether it can pass from such as 5×10 19 / cm 3 The high-concentration doping reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com