Brushless electric motor

A motor, brushless technology, applied in electrical components, electromechanical devices, other washing machines, etc., can solve the problems of increased leakage current and smaller insulation distance of washing machines, and achieve the effect of reducing leakage current and increasing insulation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, examples of embodiments of the present invention will be described with reference to the drawings.

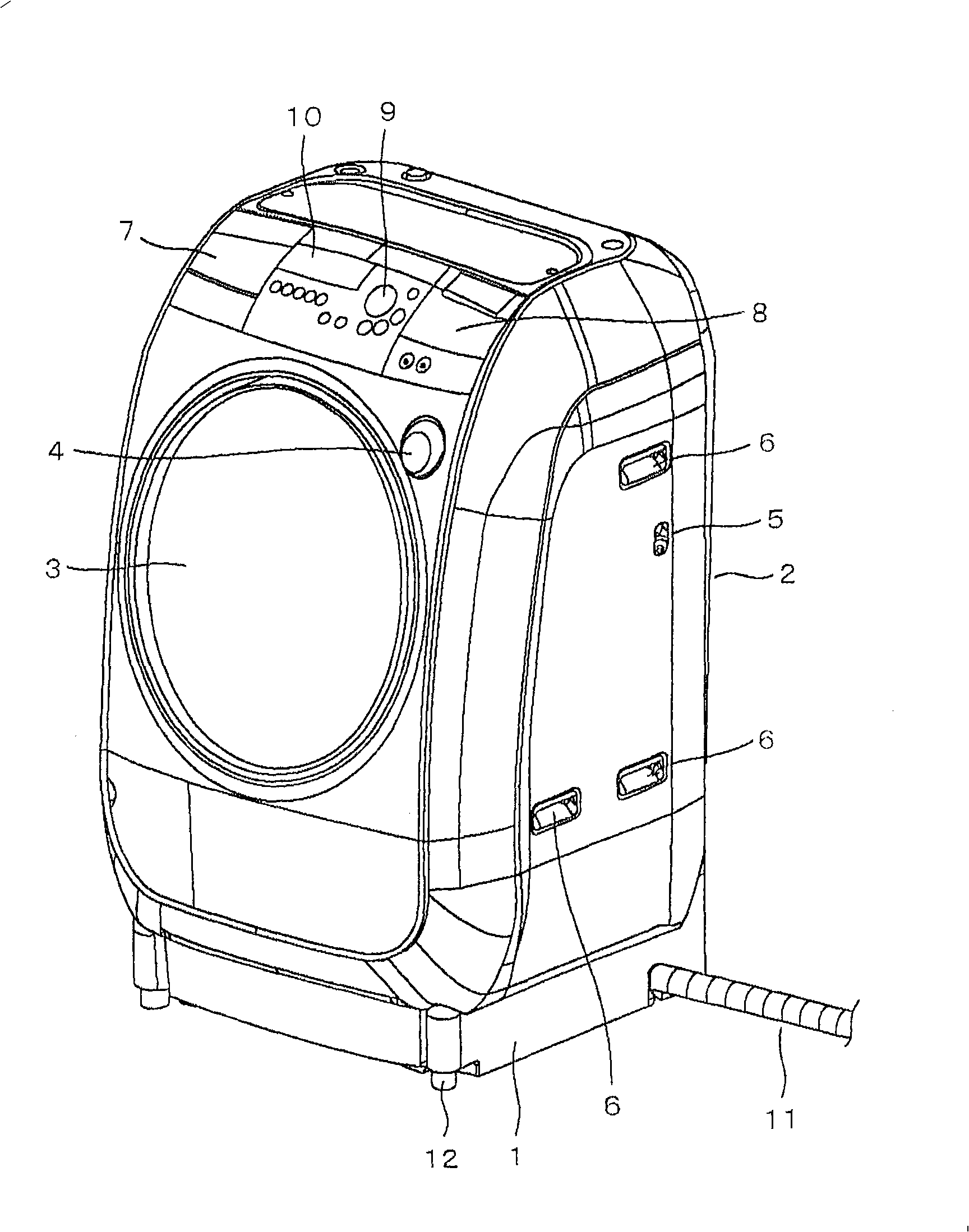

[0016] figure 1 It is a perspective view which shows the drum-type washing-drying machine of the Example of this invention.

[0017] On the upper part of the base 1 is placed an outer frame 2 composed of a combination of a resin molded product and a steel plate. A door 3 for taking out and putting in laundry is provided on the front of the outer frame 2, and a switch operation is performed with a push button switch 4. The door 3 is composed of a resin molded product with design parts on the outside and a door made of heat-resistant glass on the inside. A drain hose fixing hole 5 is provided on a side surface of the outer frame 2 . A plurality of handles 6 are provided for carrying the mobile body. In addition, a detergent pan 7 and a drying filter 8 are respectively attached to the left and right of the upper surface of the outer frame 2 . An operation ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap