electric vacuum cleaner

A vacuum cleaner, electric technology, applied in the direction of vacuum cleaners, suction hoses, household appliances, etc., can solve the problems of poor dust collection workability, achieve good retractable effect, and ensure the effect of retractable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

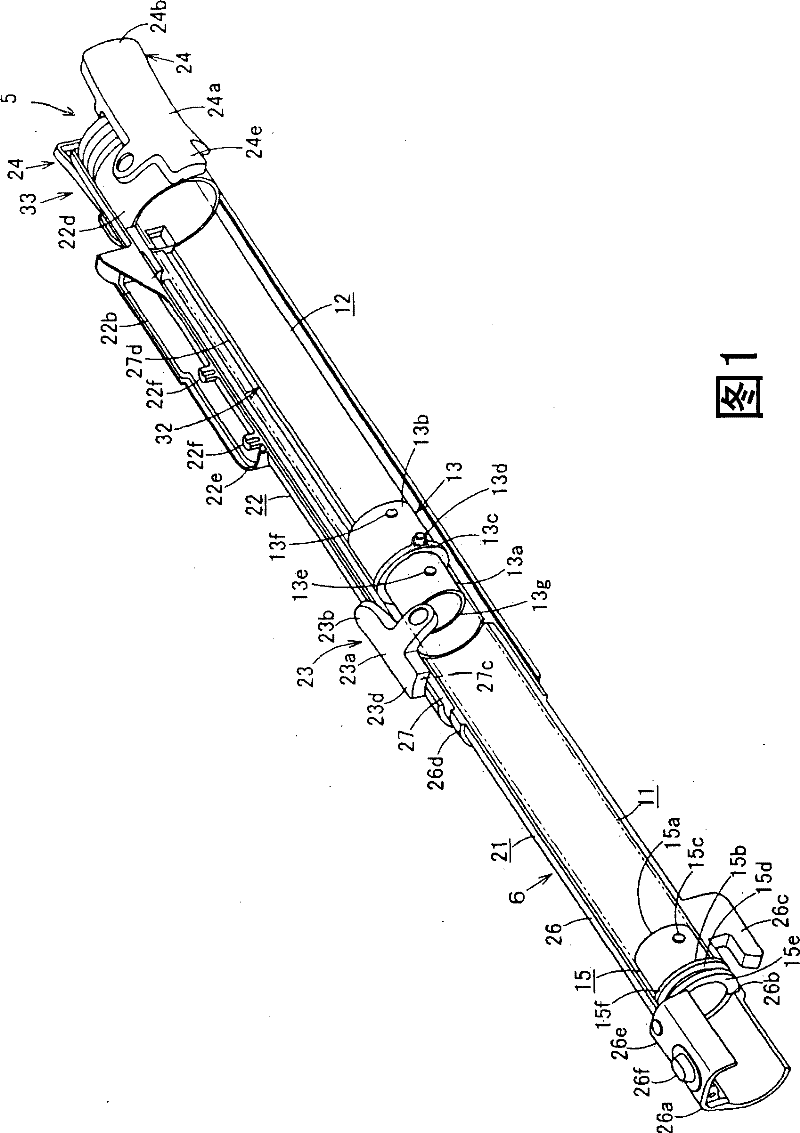

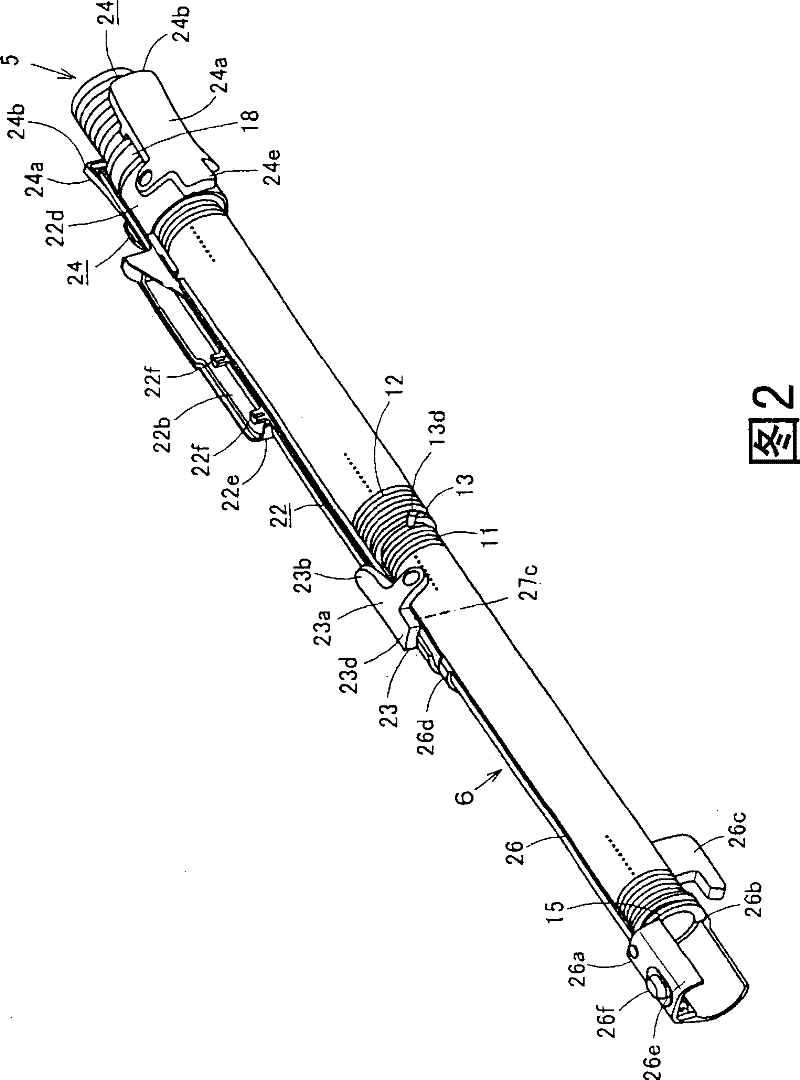

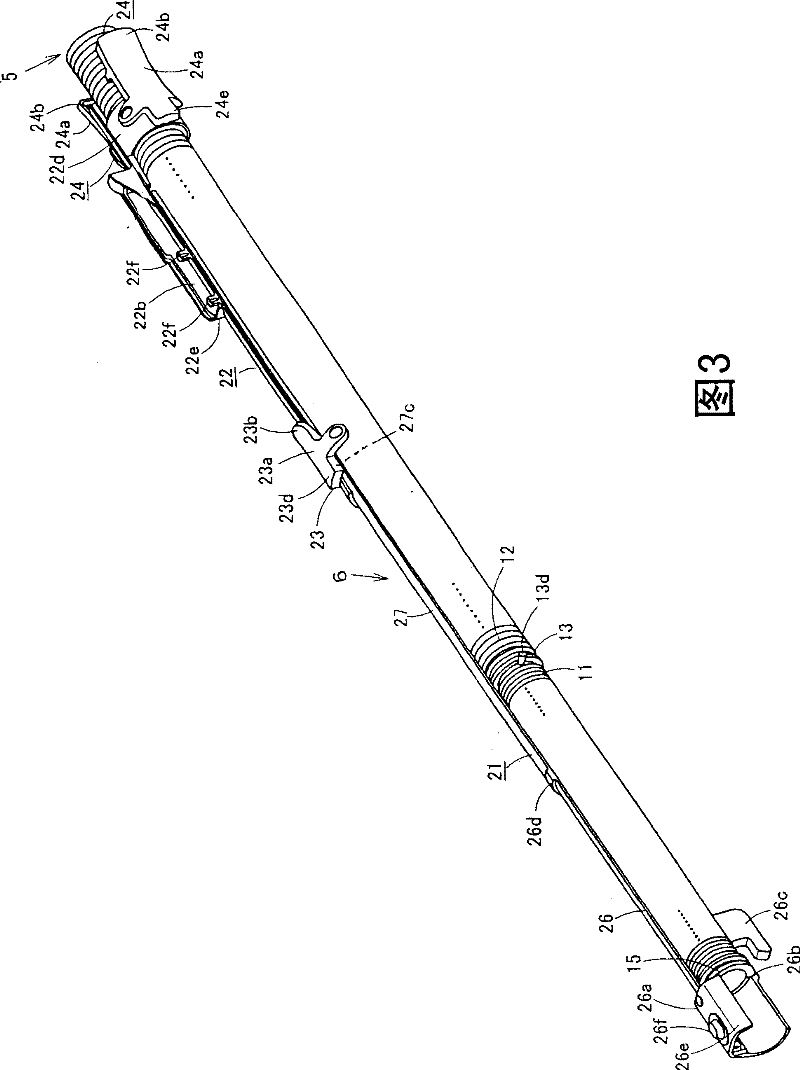

[0039] Below, refer to the appendix Figure 1 to Figure 16 The structure of the vacuum cleaner which concerns on one Embodiment of this invention is demonstrated.

[0040] Figure 15 and Figure 16 The entire structure of the electric vacuum cleaner is shown, in which 1 is the main body of the vacuum cleaner. The main body of the vacuum cleaner 1 generates suction wind while inhaling dust through the drive of the electric blower 2 housed inside, and collects the dust in a removable paper bag or as a dust collector. The dust collecting part such as the dust collecting cup of the device is not shown in the figure.

[0041] Moreover, in this cleaner main body 1, the main body suction port 3 which draws in air from the outside is opened, and the detachable pipe part 4 is connected to this main body suction port 3. As shown in FIG. Moreover, this cleaner main body 1 has wheels which can move on the ground of the surface to be cleaned. However, it demonstrates as upstream and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com