Method for heating heat roller and heat roller

A heating method and technology of heating rollers, which are applied in the heating field of heating rollers, can solve problems such as weak thermal conductivity, uneven temperature distribution on the working surface of heating rollers, and influence on the uniformity of heat transfer coefficients, etc., and achieve rapid and uniform temperature distribution , easy to implement in industrialization, and the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

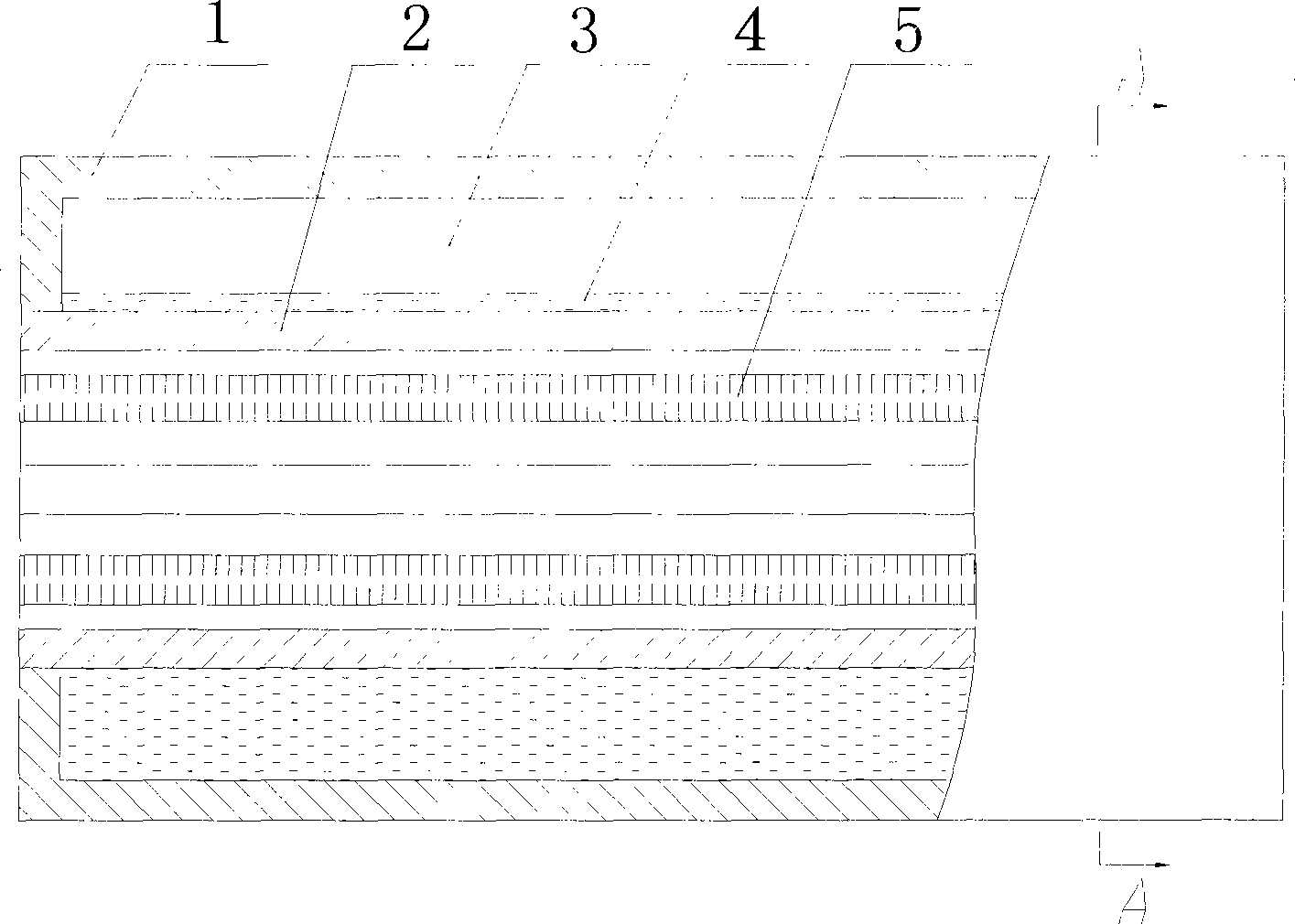

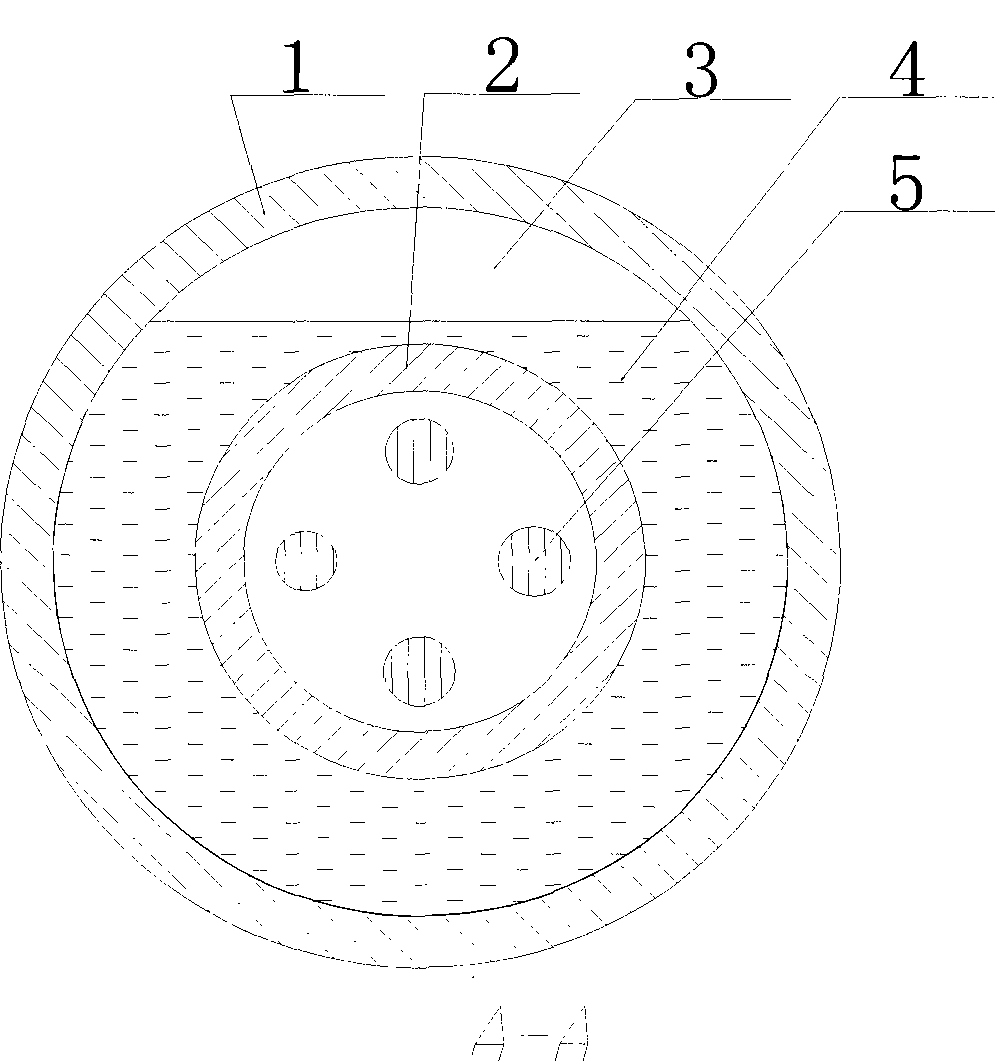

[0038] According to the simple heating roller of the heating method basic requirement design of the present invention (referring to figure 1 , 2 ).

[0039] The heating roller includes an outer roller 1 and a casing 2 installed therein. The annular cavity between the casing 2 and the outer roller 1 is a closed cavity 3, and four sets of heat sources 5 are evenly distributed in the casing 2. The cavity 3 is filled with a heat medium 4, and its characteristic structure is that the annular airtight cavity 3 is a vacuum airtight cavity, and the liquid heat medium 4 that has submerged the upper surface of the casing 2 is sealed in the cavity 3, and the remaining volume is Vacuum state; the liquid heat medium 4 is water; the heat source 5 is an electric heating tube.

Embodiment 2

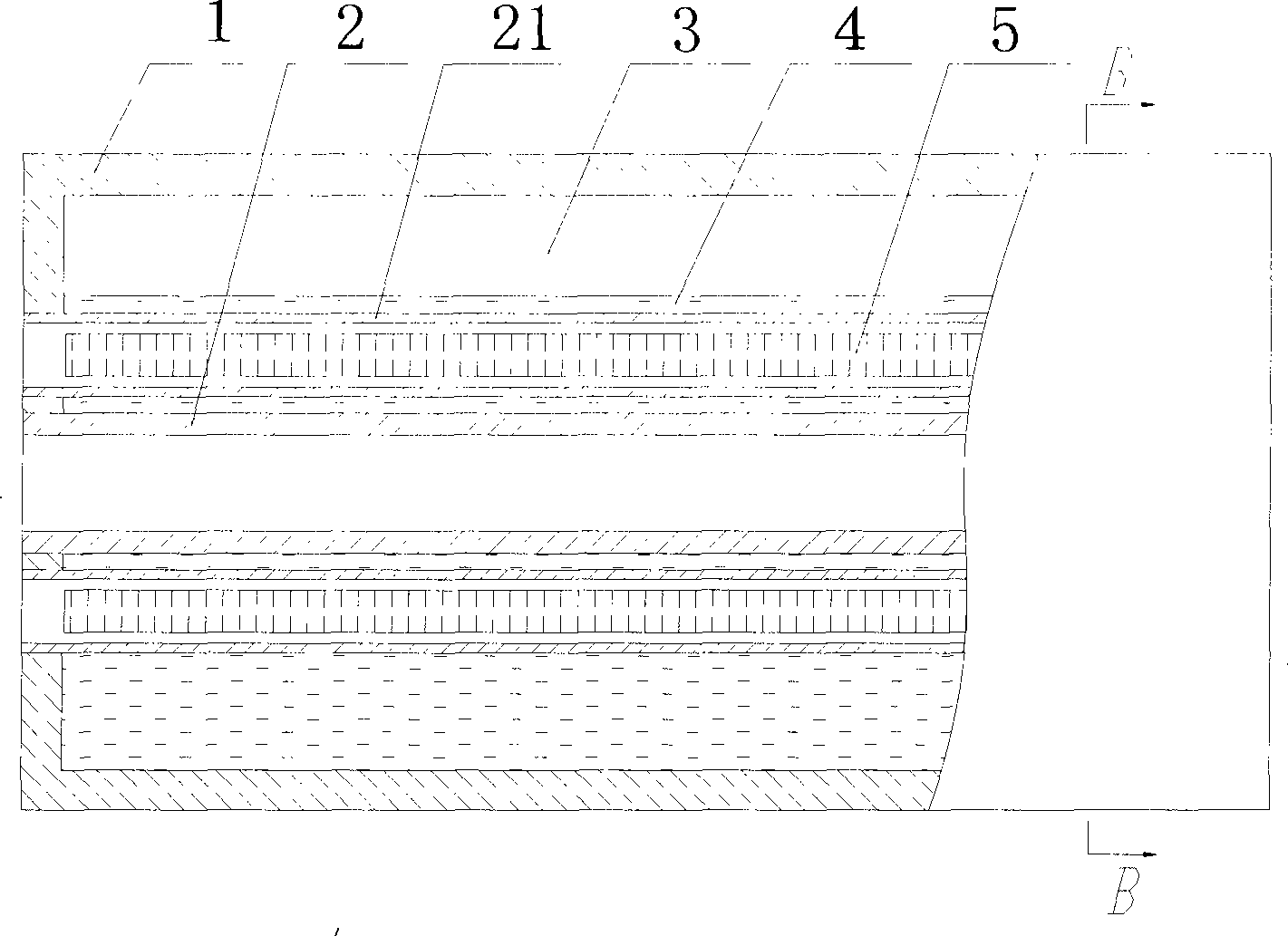

[0041] Another simple heating roller designed according to the basic requirements of the heating method of the present invention (see image 3 , 4 ).

[0042] The characteristic structure of the heating roller is that the diameter of the sleeve 2 is reduced, and the four sets of heat sources 5 are uniformly installed in the annular cavity 3 outside the sleeve 2 and are respectively fitted with heat source sleeves 21 . The rest are the same as embodiment 1.

Embodiment 3

[0044] According to the improvement of heating method of the present invention, a heating roller (referring to) that a heating medium container of design is arranged Figure 5 , 6 ).

[0045] The heating roller includes an outer roller 1 and a casing 2 installed therein. The annular cavity between the casing 2 and the outer roller 1 is a closed cavity 3, which is filled with a liquid heat medium heat transfer oil 41. The casing 2 A group of induction heating devices 51 are installed inside, and its characteristic structure is that the annular airtight cavity 3 is a vacuum airtight cavity, and an open rectangular heat medium container 6 is designed, which is set on the outside of the sleeve 2, and the The liquid heat medium heat transfer oil 4 is filled into the space between the heat medium container 6 and the sleeve pipe 2, so that the heat transfer oil 41 is out of contact with the outer roller 1 of the heating roller, and only the heat that escapes smoothly from the heat m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com