Method for cleanly producing saponin by comprehensively utilizing turmeric

A clean and saponin technology, applied in organic chemistry, pharmaceutical formulations, steroids, etc., can solve the problems of high production cost, large waste water, difficult dehydration and concentration, etc., and achieve increased yield, simple process steps, and reduced dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

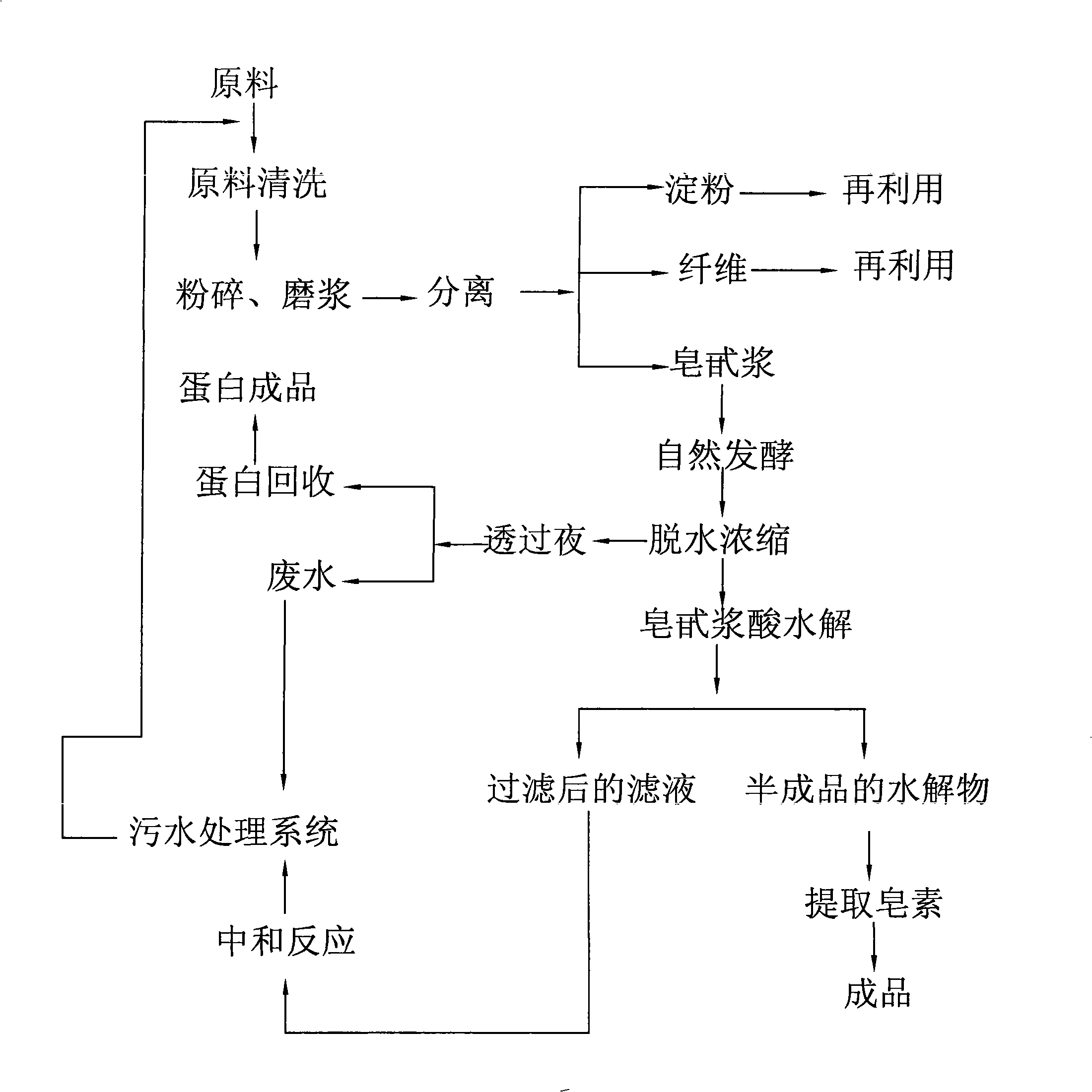

[0013] according to figure 1 The process flow chart shown in detail describes the present invention as follows:

[0014] A method for comprehensively utilizing yellow ginger to cleanly produce saponin is realized by the following process steps:

[0015] (1) Raw material pretreatment: cleaning yellow ginger, crushing with a crusher, after crushing, grinding into a slurry with a pin mill, so that the particles in the slurry reach 18-22 mesh, and the mass percentage concentration is 10-15%;

[0016] (2) Extract saponin slurry: use two horizontal spiral unloading sedimentation centrifuges for two-stage separation to separate the saponins with a lighter specific gravity from fiber and starch to obtain saponin slurry; fiber and starch are reused;

[0017] (3) Naturally ferment the saponin slurry at 34-38°C for 24 to 36 hours;

[0018] (4) Dehydration and concentration: the fermented saponin slurry is filtered through ultrafiltration membranes and discs to obtain a concentrated saponin s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap