Inclined type double-face circular disc knitting machine

A kind of knitting machine, tilting technology, applied in the field of tilting double-sided circular knitting machine, can solve the problems of slipping, inconvenience, poor weaving elasticity, etc., and achieve large rib elastic structure, uniform size, consistent needle mesh Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

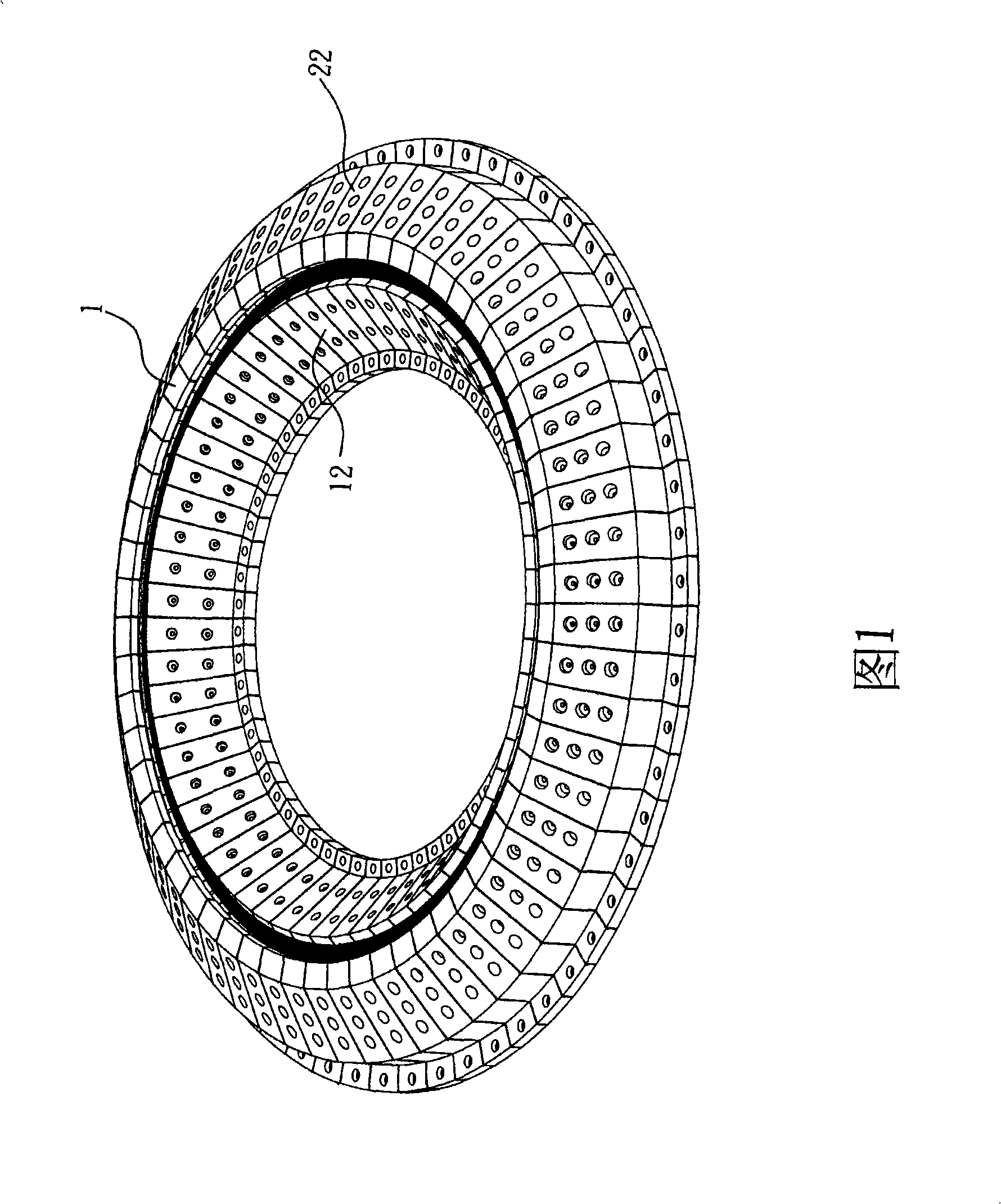

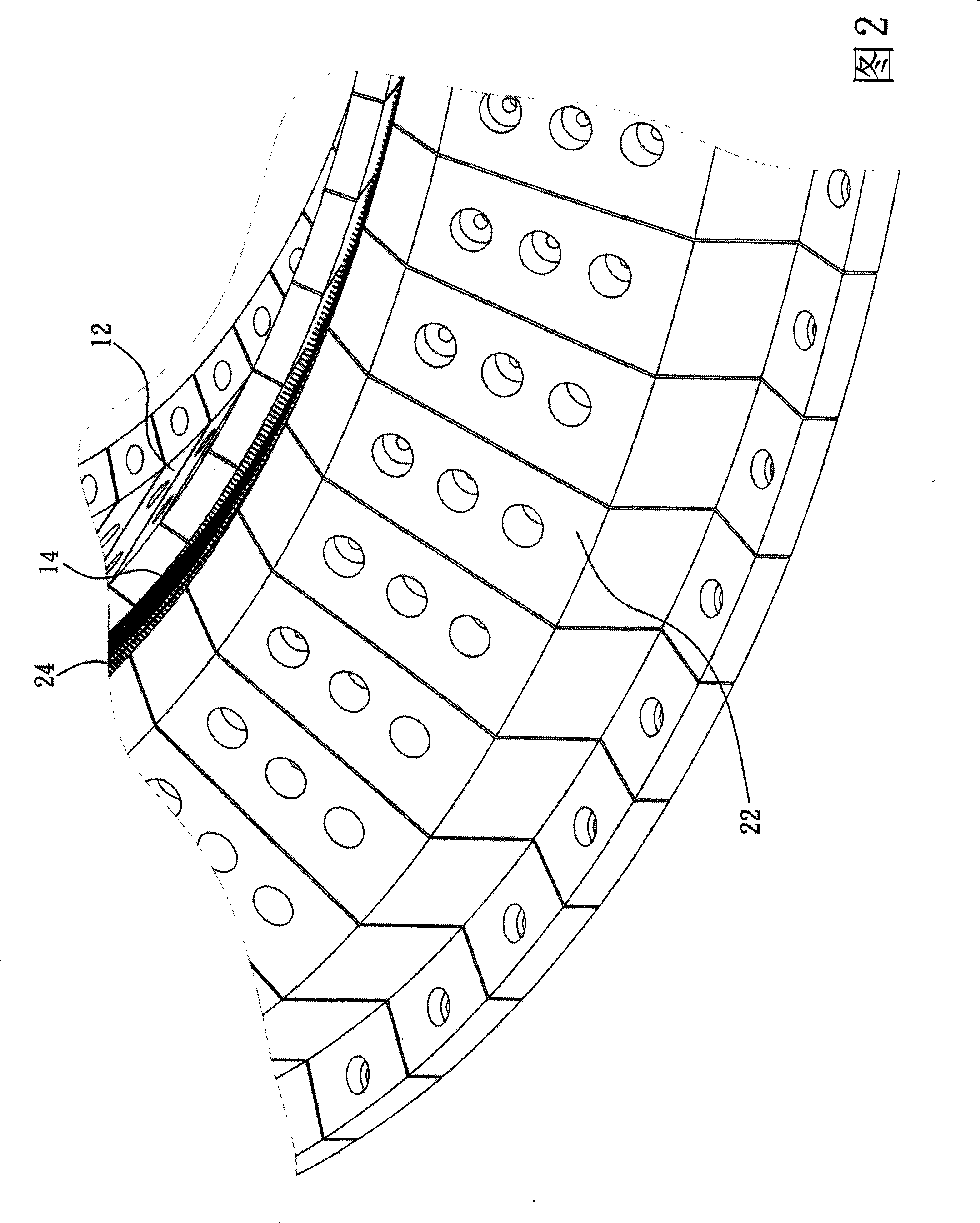

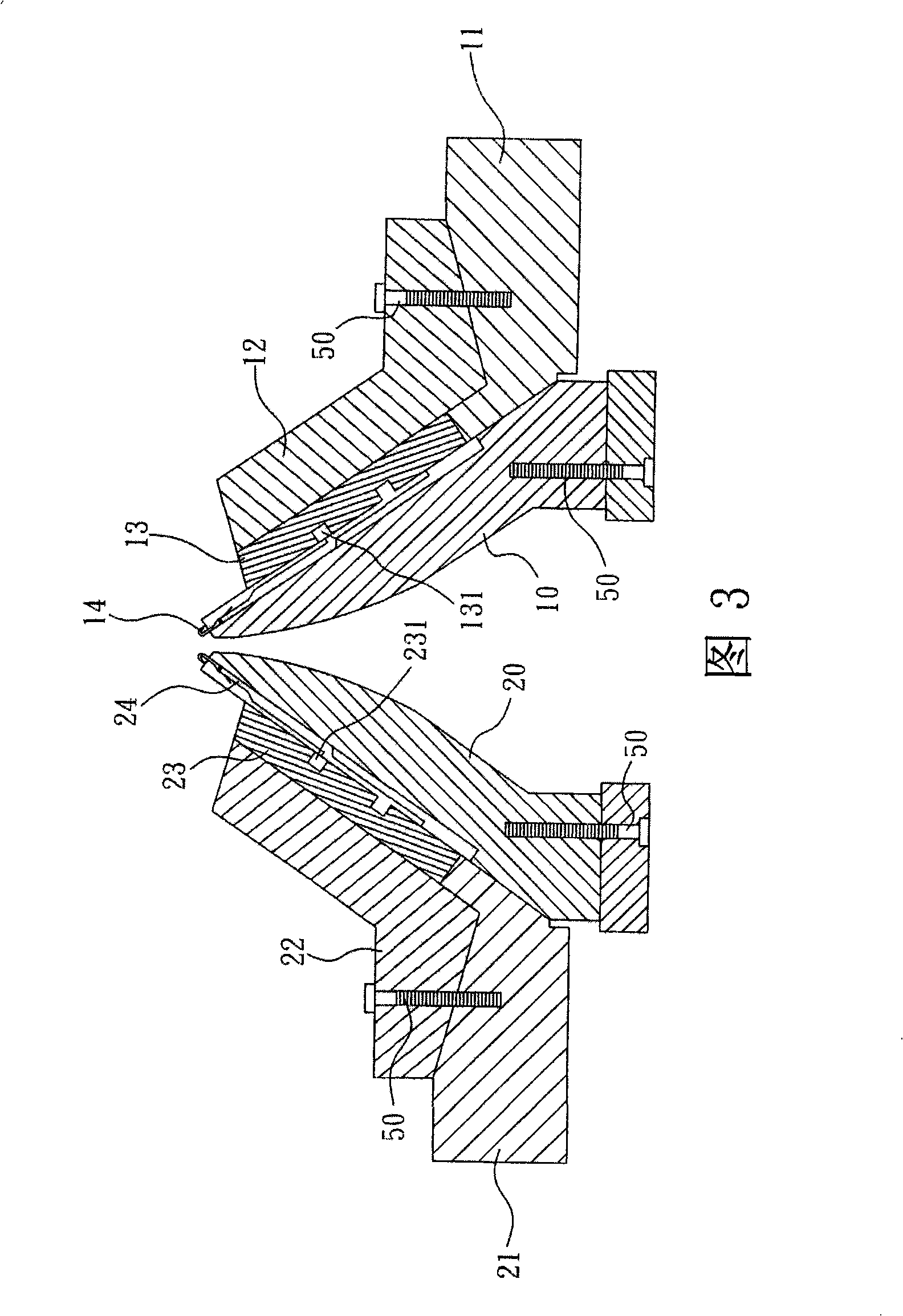

[0024] As shown in Figures 1 to 3, basically, the double-sided disc knitting machine of this case includes a disc 1, which is provided with two ring-shaped inner and outer needle cylinder seats 10, 20, and the inner and outer needle cylinder seats 10, 20 The mouth openings at the upper ends of the outer syringe holders 10, 20 present a pair of inward and outward symmetrical splayed angles, such as preferably 50 to 60 degrees, most preferably 55 degrees.

[0025] Wherein, the inner side of the inner syringe base 10 is adjacent to an inner chassis 11, and a plurality of inner cam adjustment parts 12 are fixed above the inner chassis 11. Arranged in a ring, each inner cam adjustment member 12 is provided with an inner cam block 13 on the bottom surface. The needle track 131 of predetermined shape can make each inner knitting needle 14 move back and forth in the needle track 131 of the inner cam block 13 to carry out the operation of weaving.

[0026] The outer side of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com