Auxiliary terminal needle bed component of electrical energy meter calibration stand connection device

A technology of auxiliary terminals and wiring devices, applied in measuring devices, measuring electrical variables, instruments, etc., can solve the problems of high labor intensity of operators, inconsistent contact strength, poor wiring contact, etc., to increase wiring reliability, and calibrate meter wiring. The effect of standardizing and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

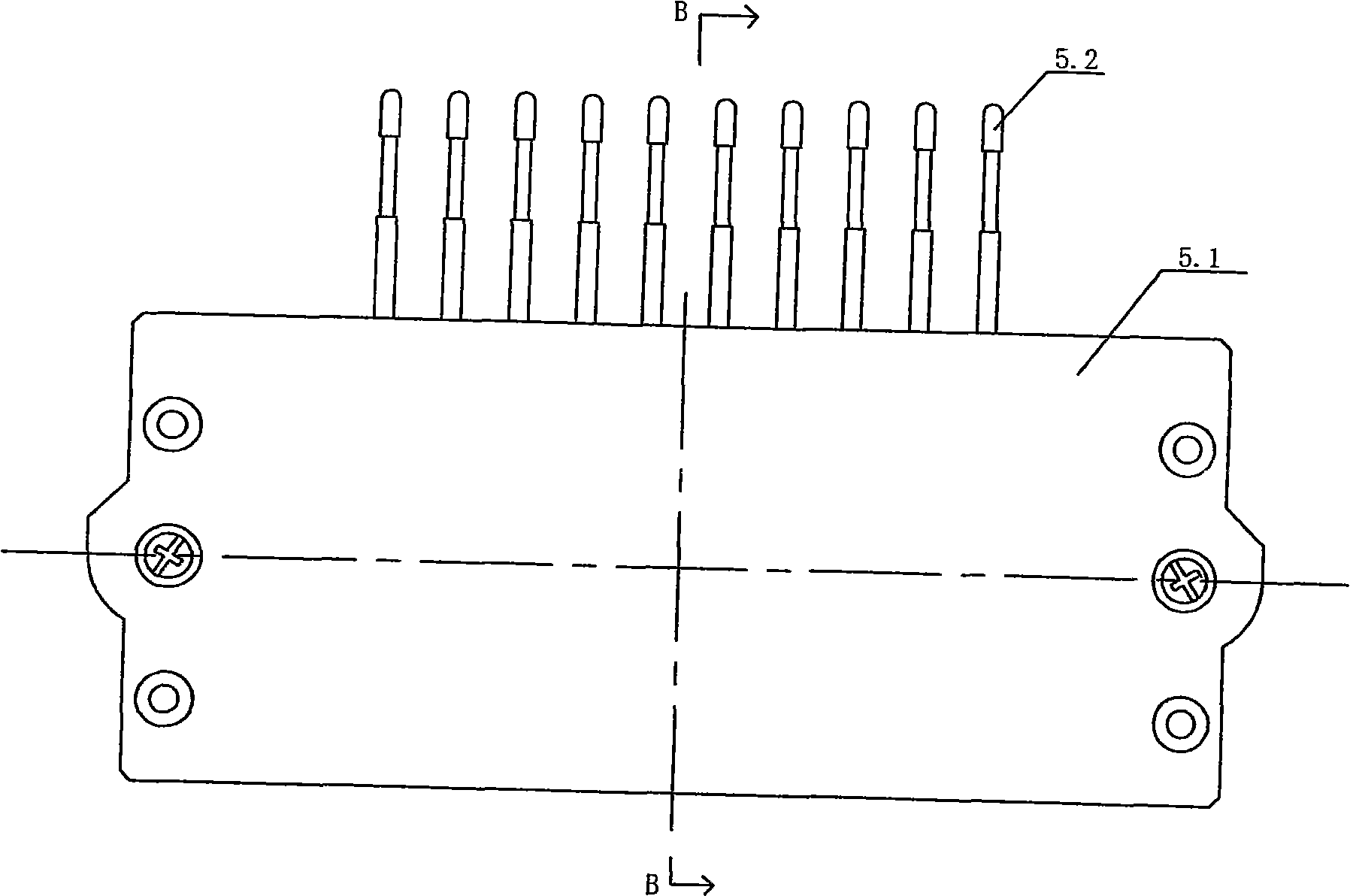

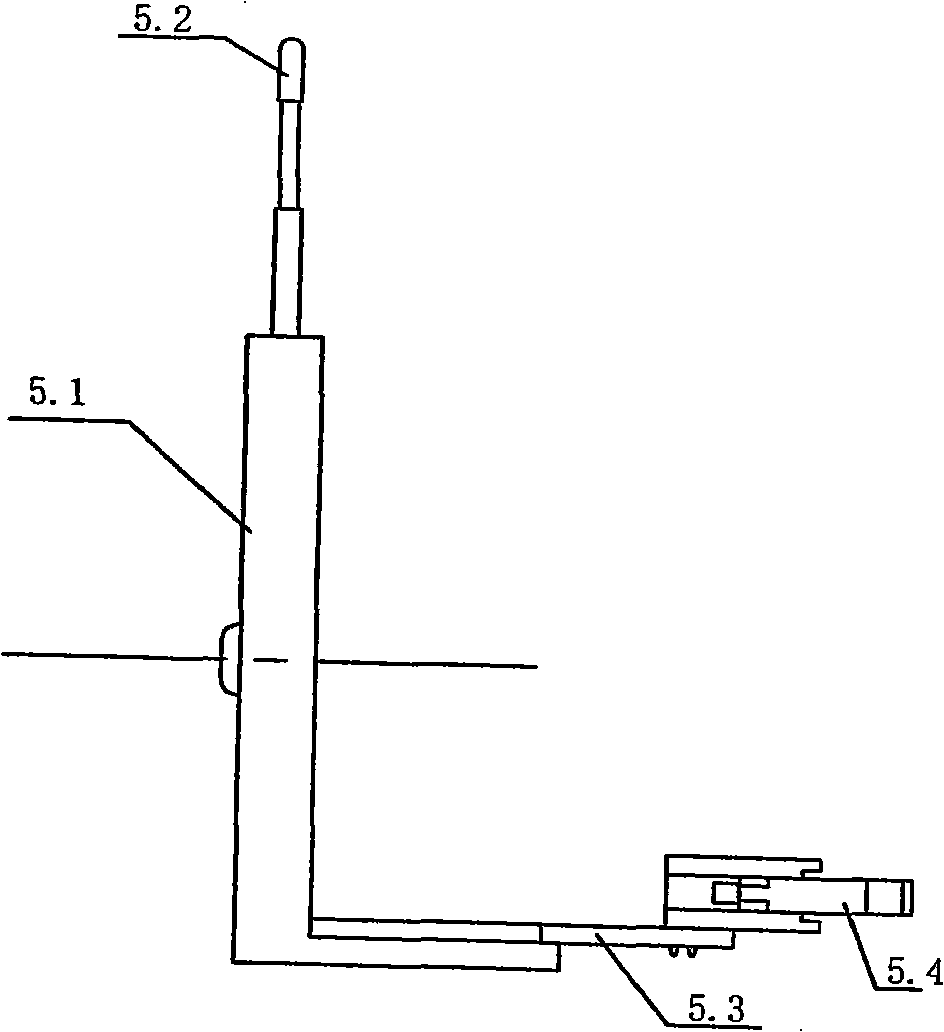

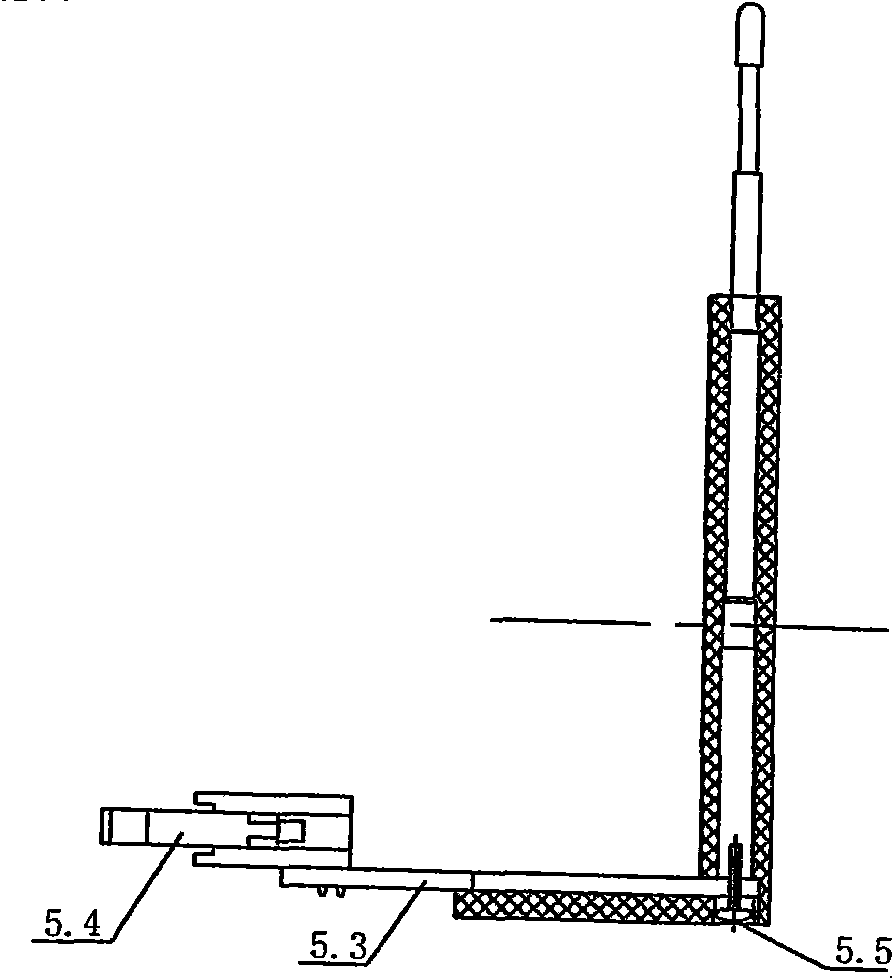

[0010] see Figure 1~3 , the auxiliary terminal needle bed assembly of the electric energy meter calibration station wiring device of the present invention is mainly composed of auxiliary terminal needle bed body 5.1, auxiliary terminal probe 5.2, circuit board (PBC board) 5.3 and (multi-core) socket 5.4. The auxiliary terminal needle bed body 5.1 is fixedly connected to the front side of the wiring device box body with fixing studs, there is a row of auxiliary terminal probes 5.2, and a row of auxiliary terminal probes 5.2 is vertically inserted into the auxiliary terminal needle bed body 5.1 The upper end of the auxiliary terminal probe 5.2 extends out of the auxiliary terminal needle bed body 5.1, the lower end of the auxiliary terminal probe 5.2 is connected with the circuit board 5.3 with a screw 5.5, and the (multi-core) socket 5.4 is connected with the circuit board 5.3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap