Inner circle self-locking sling

A technology of self-locking and slings, applied in the direction of load hanging components, manufacturing motor generators, electrical components, etc., can solve problems such as inconvenient assembly, low work efficiency and product quality, easily damaged stator enameled wires, etc., to achieve convenient hoisting, Low cost and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

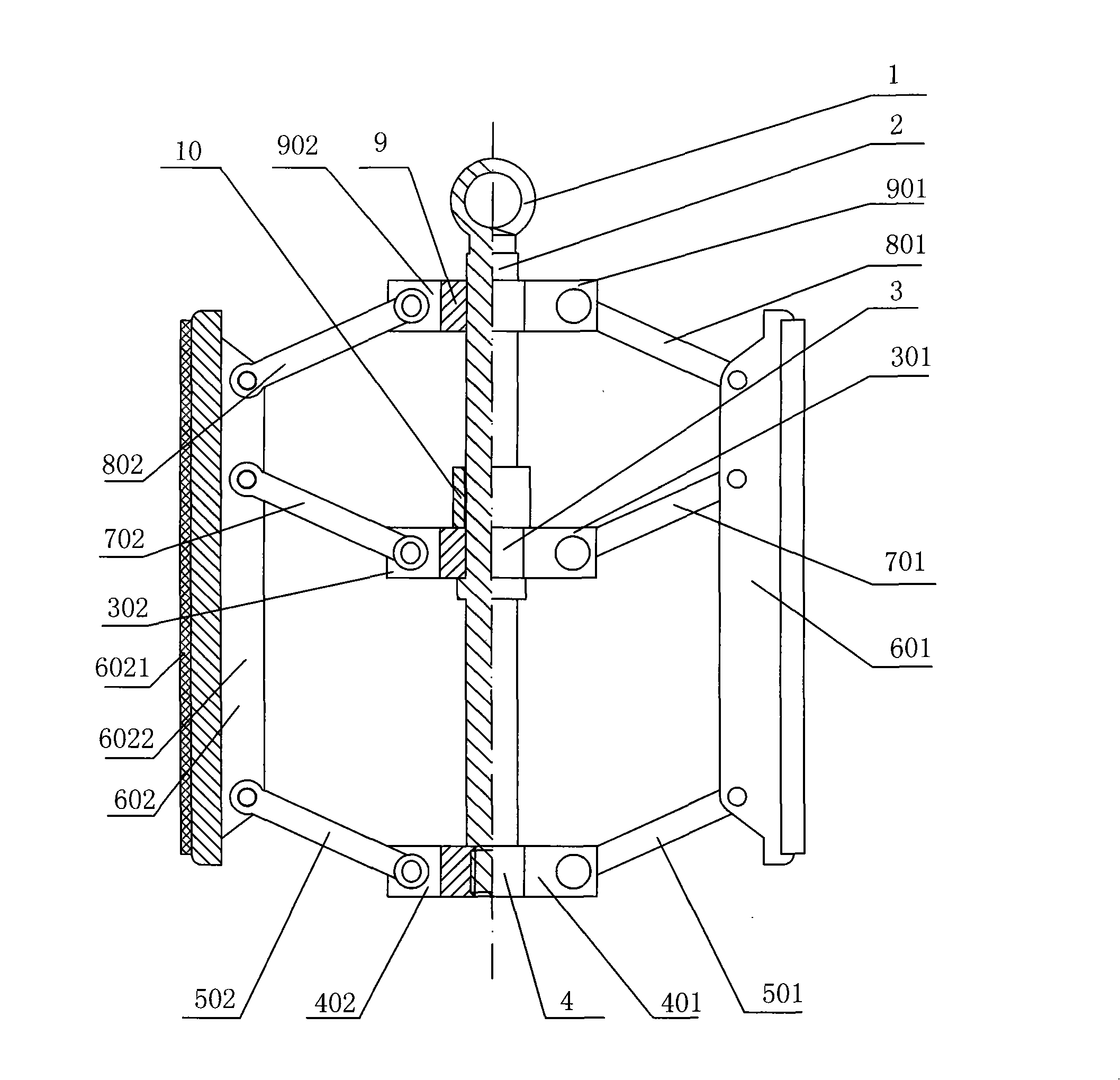

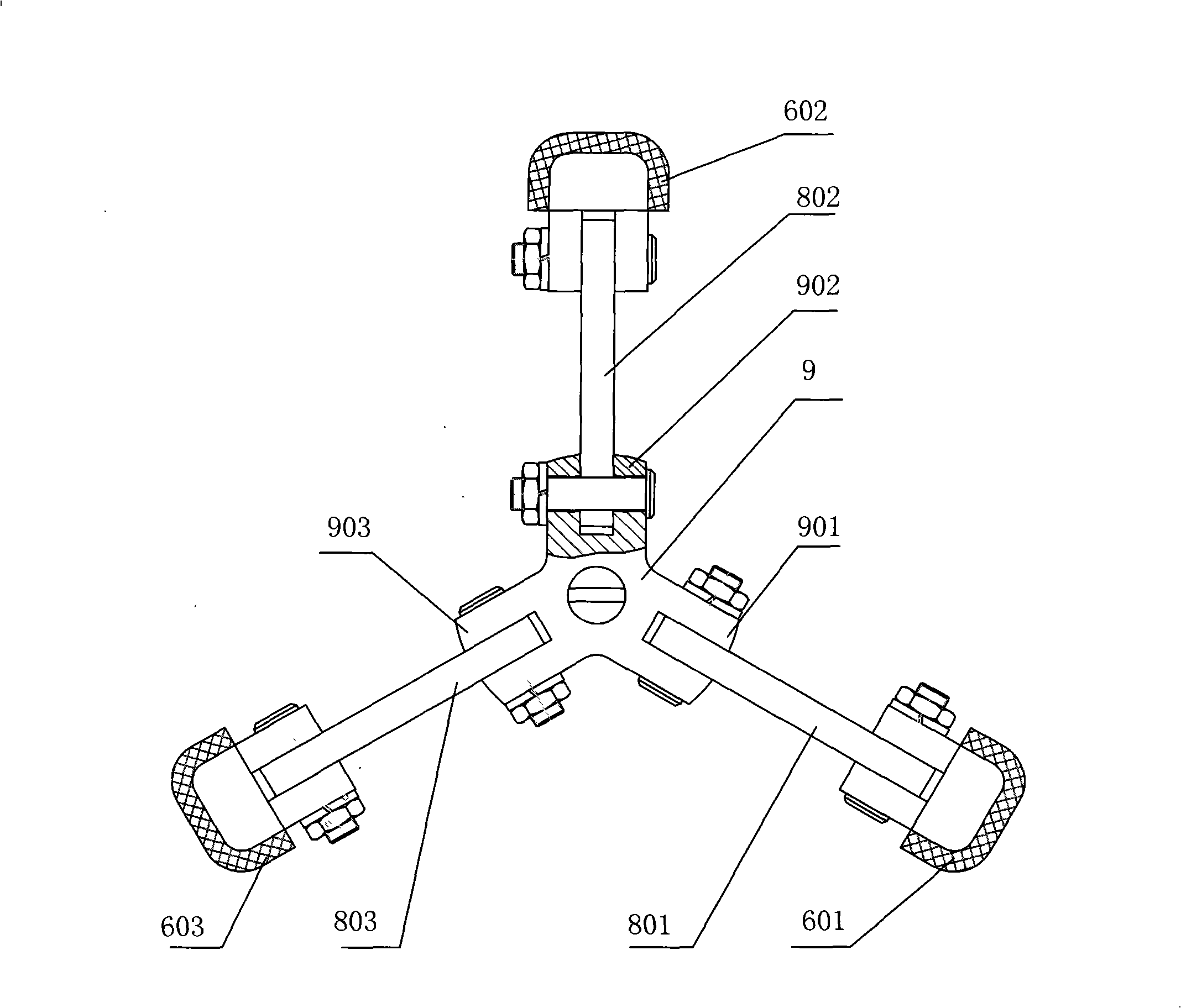

[0015] exist figure 1 Among them, an inner circle self-locking sling, including a hoisting receiving part 1, the hoisting receiving part 1 can adopt a ring structure, a hook structure, or other structures that can be connected with a crane. In this embodiment, Preferred ring construction.

[0016] Such as figure 1 As shown, an inner circle self-locking sling also includes a tie rod 2 welded and fixed to the lifting socket 1 . Pull rod 2 is an optical axis.

[0017] A first positioning member 3 and a second positioning member 4 are sequentially fixedly mounted on the pull rod 2 .

[0018] The first positioning member 3 is fixed on the pull rod 2 by cooperating with the shoulder on the pull rod 2 and the fixing nut 10 matched with the pull rod 2 .

[0019] The second positioning member 4 is threadedly connected with the pull rod 2 to be fixed at the end of the pull rod 2 .

[0020] figure 1 Among them, two connecting frames 301 , 302 are symmetrically arranged on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com