Unfolding type absorbent article and process for producing back sheet for absorbent article

An absorbent and article technology, which is applied in the field of unfolded absorbent articles and back sheets for absorbent articles, can solve the problems of hard back sheets, poor feeling, damage of non-woven sheets, etc., and achieves excellent touch and softness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

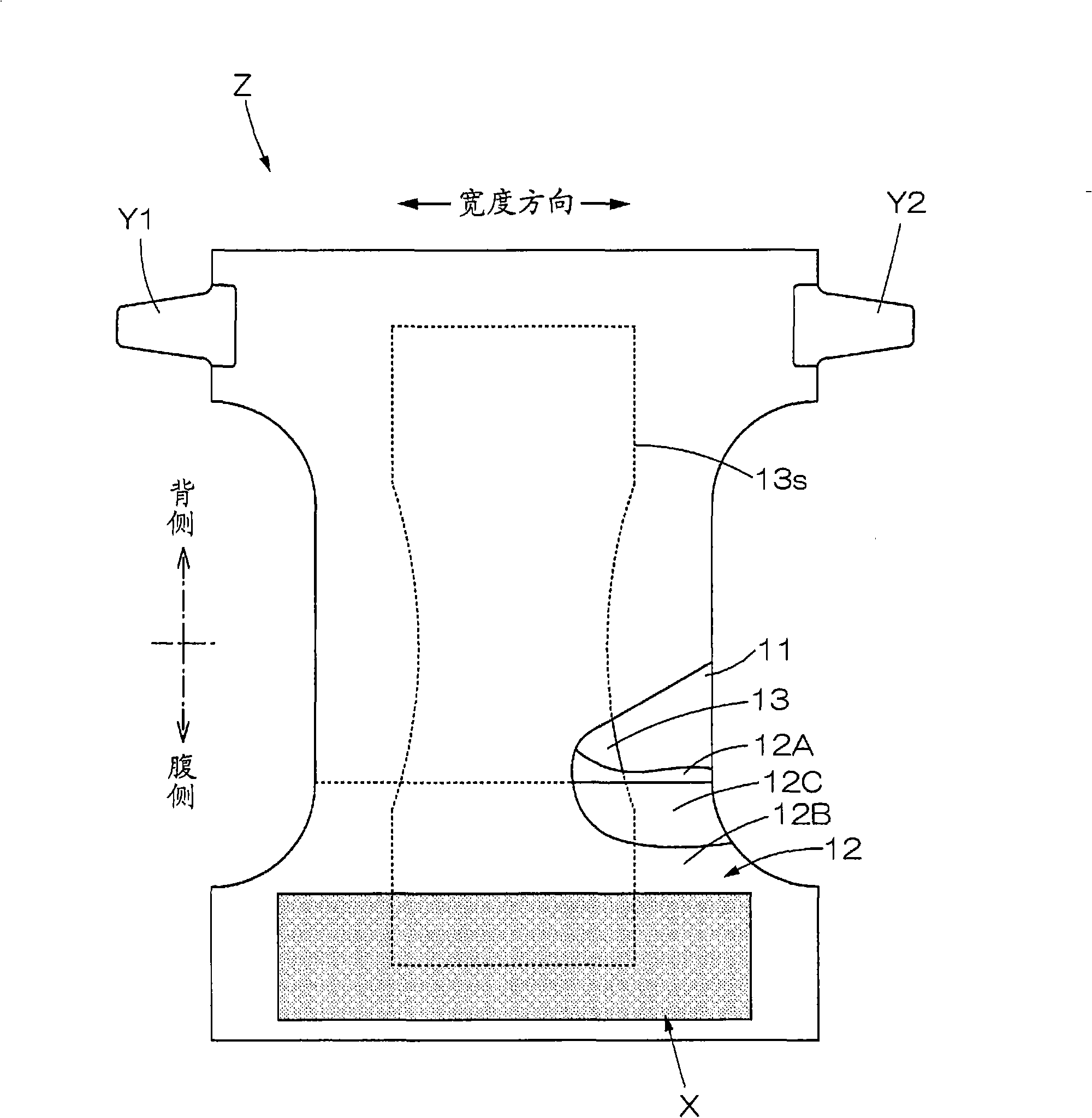

[0095] figure 1 It is a developed view showing the fastening type disposable diaper Z of the present invention. This disposable diaper Z has: a liquid-permeable top sheet 11 positioned on the user's skin side; a liquid-impermeable back sheet 12 positioned on the outside of the product that does not allow liquid to permeate substantially; The absorber 13 is preferably hourglass-shaped and has a certain degree of rigidity, and the fastening tapes Y1 and Y2 for fastening are arranged on the left and right sides of the back side. In this form, the fastening tapes Y1, Y2 are formed using a hook surface material of a surface fastener, and an engaging portion X for engaging with an exposed portion of the hook surface material is formed on the ventral portion of the outer surface of the back sheet 12. superior.

[0096]The back sheet 12 is formed in a substantially square shape wider than the absorber 13, and the nonwoven fabric sheet 12B for exterior is laminated on the outer surfa...

no. 2 approach

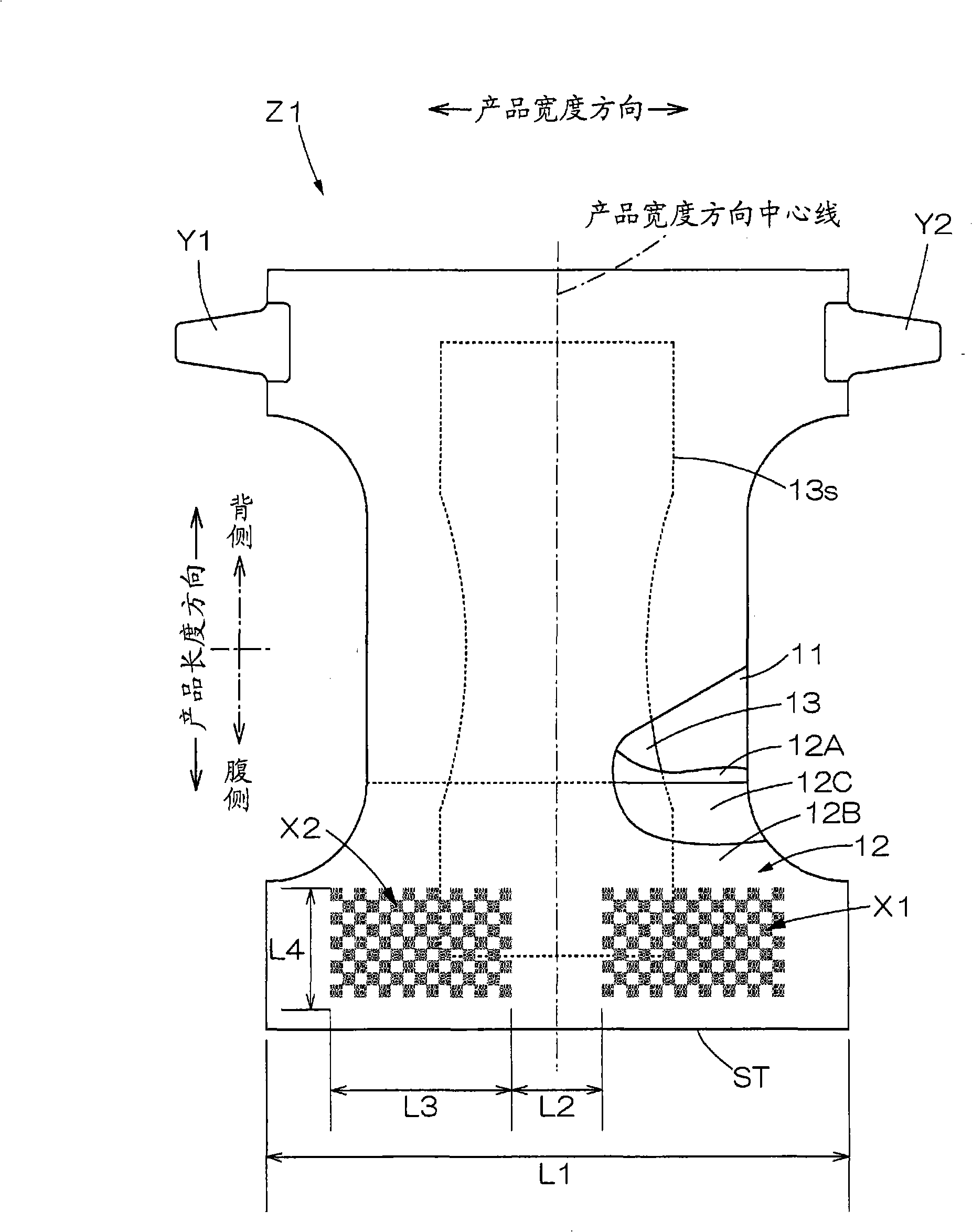

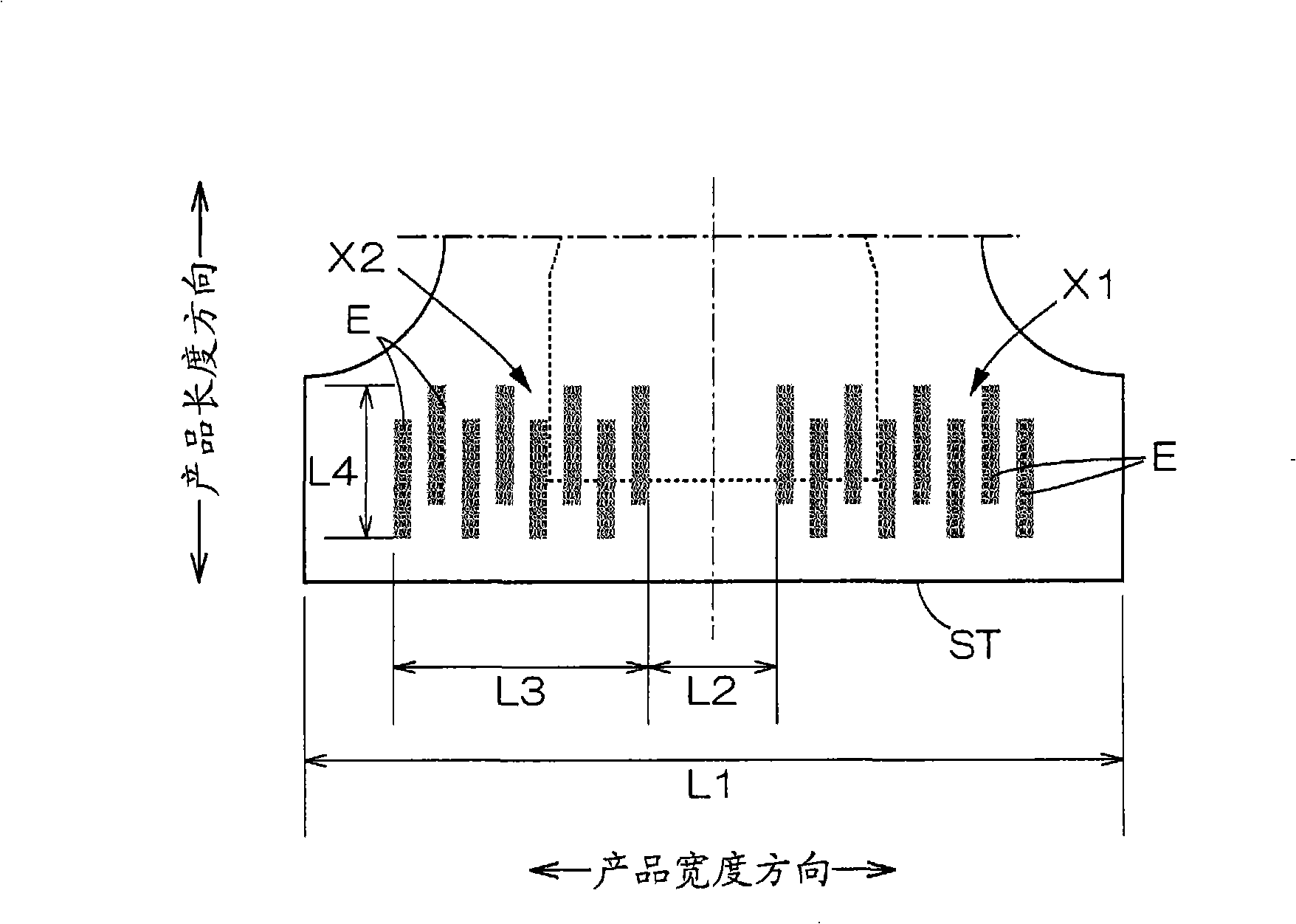

[0115] figure 2 It is fastening type disposable diaper Z1 which concerns on 2nd Embodiment. Since the basic structure of this disposable diaper Z is the same as that of 1st Embodiment, the same code|symbol is used for the same part, and description is abbreviate|omitted.

[0116] In the second embodiment, a method called a so-called non-target tape is adopted, that is, a part of the outer surface of the back sheet 12 itself is appropriately embossed without attaching a matte material to the back sheet, thereby forming Joints X1, X2. Furthermore, on the back sheet 12, the intermediate nonwoven fabric sheet 12C is arranged between the exterior nonwoven fabric sheet 12B and the water-repellent sheet 12A within the range including the junction portions X1 and X2 formed therein.

[0117] The fastening belts Y1 and Y2 arranged on the left and right sides of the back side are made of the hook surface material (not shown) of the surface buckle except for the parts glued to the left...

no. 3 approach

[0133] Figure 5 and Fig. 6 show a third embodiment of the disposable diaper Z2. Figure 6 is along the Figure 5 A sectional view of the 2-2 line. The unfolded disposable diaper 10 includes: a back sheet 12 constituting the outer surface of the diaper; a liquid-permeable top sheet 30 disposed on the skin side; an absorber 50 interposed between the exterior sheet 12 and the top sheet 30; Fastening tapes Y1, Y2 on both ends of the back side of the back sheet 12. Fastening tape Y1, the fastening surface of Y2 is provided with hook surface material 130A, when wearing diaper, the fastening tape Y1 of the back side, the hook surface material 130A of Y2 is joined to the arbitrary place of the abdominal side surface of back sheet 12. .

[0134] (surface sheet)

[0135] The topsheet 30 is formed in a rectangle wider than the absorbent core 56, extends slightly outward from the sides of the absorbent core 56, and is fixed to the backsheet 12 with a hot melt adhesive or the like.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com