Quieter of electrical heating cooker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

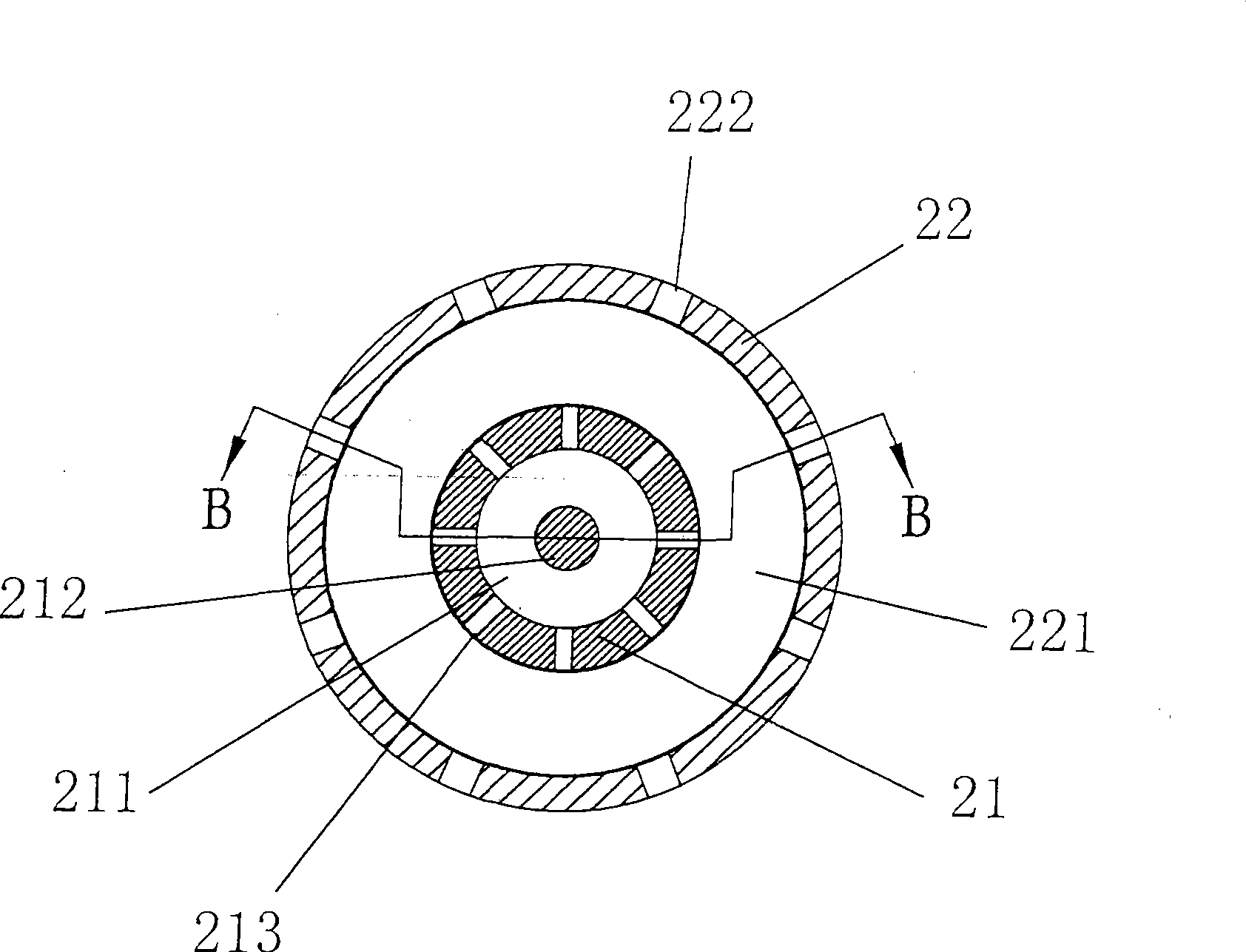

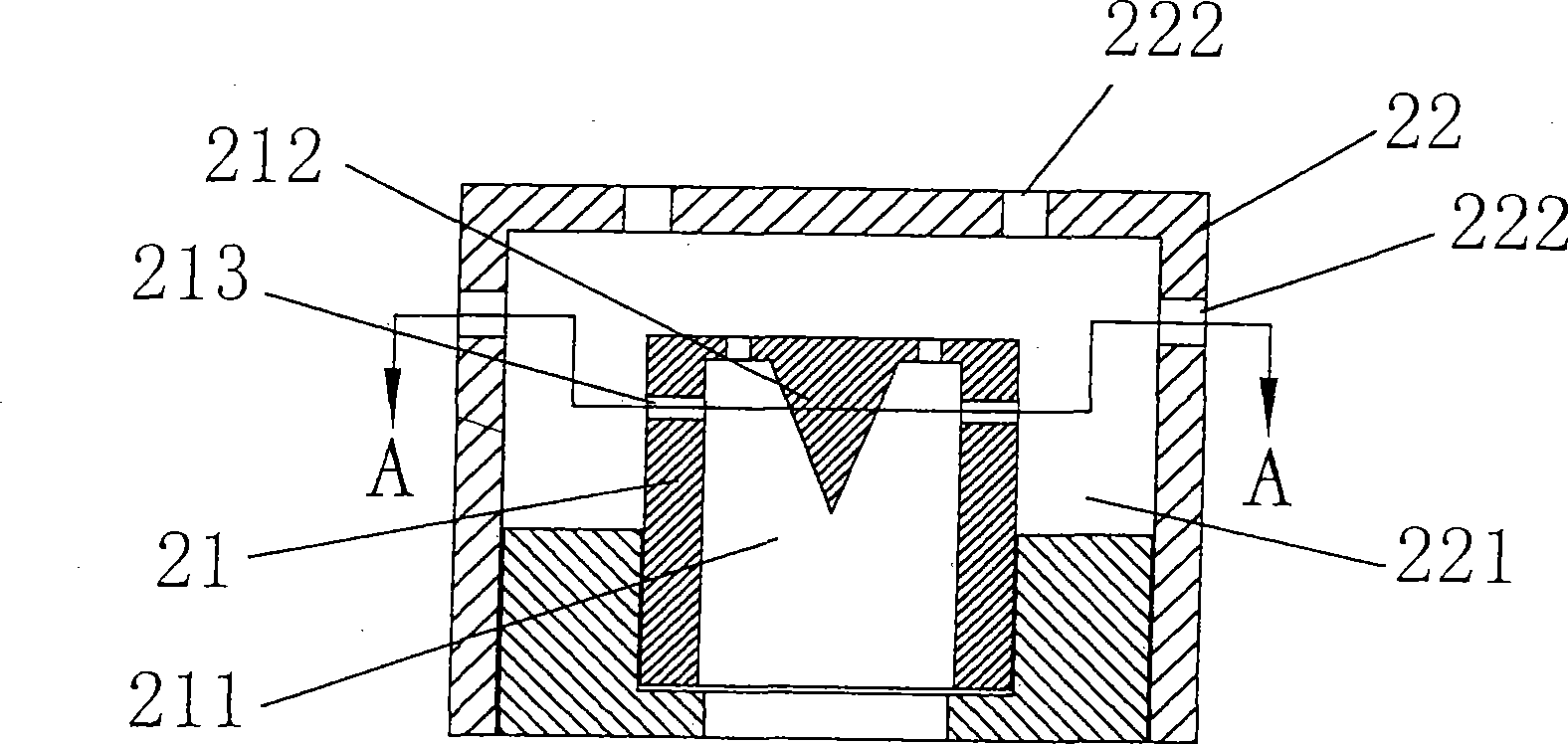

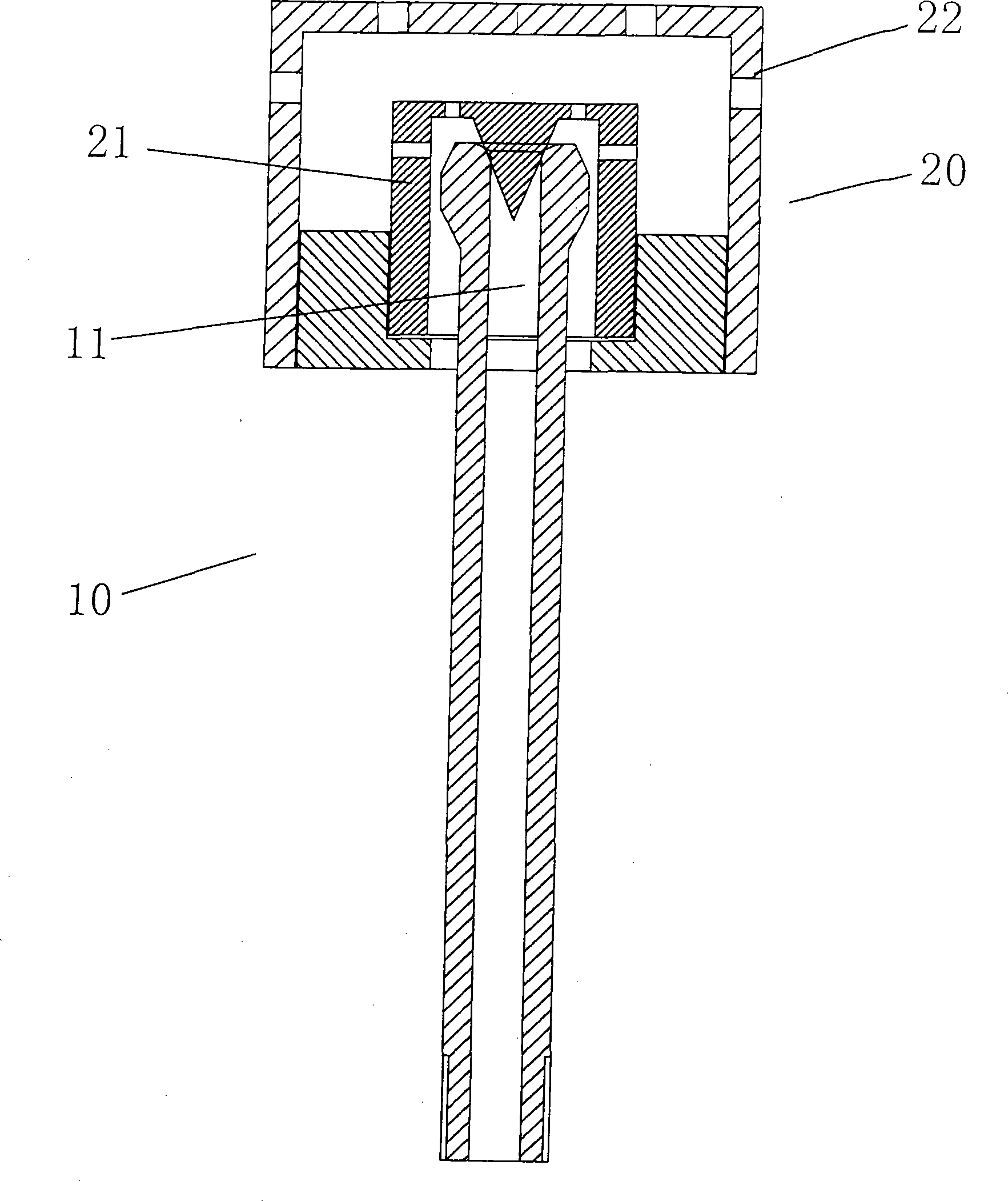

[0014] Such as Figure 1-4 As shown, the present invention includes an electric heating cooker body, an exhaust valve core 10 is installed on the electric heating cooker body, and a gravity valve 20 is provided at the position of the air outlet 11 of the exhaust valve core 10. The gravity valve 20 includes The exhaust valve body 21 and the exhaust valve cover 22. One end of the exhaust valve body 21 is provided with a plug cavity 211 into which the air outlet 11 of the exhaust valve core 10 is inserted, and the exhaust valve body 21 is provided with an exhaust The valve plug 212 matched with the outlet 11 of the spool 10; the exhaust valve cover 22 covers the outside of the exhaust valve body 21 and forms a cavity 221 with the outer surface of the exhaust valve body 21; in the exhaust valve body 21 There are several vent holes 213 on the top, several vent holes 222 on the exhaust valve cover 22, the vent holes 213 on the exhaust valve body 21 and the vent holes on the exhaust valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com