Configuring structure of smoke-discharging blower fan and chimney

A configuration structure, smoke exhaust fan technology, applied in exhaust gas device, air induction, combustion product treatment, etc., can solve problems such as surge, insufficient fan output, etc., to reduce resistance, improve running stability, and reduce resistance consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

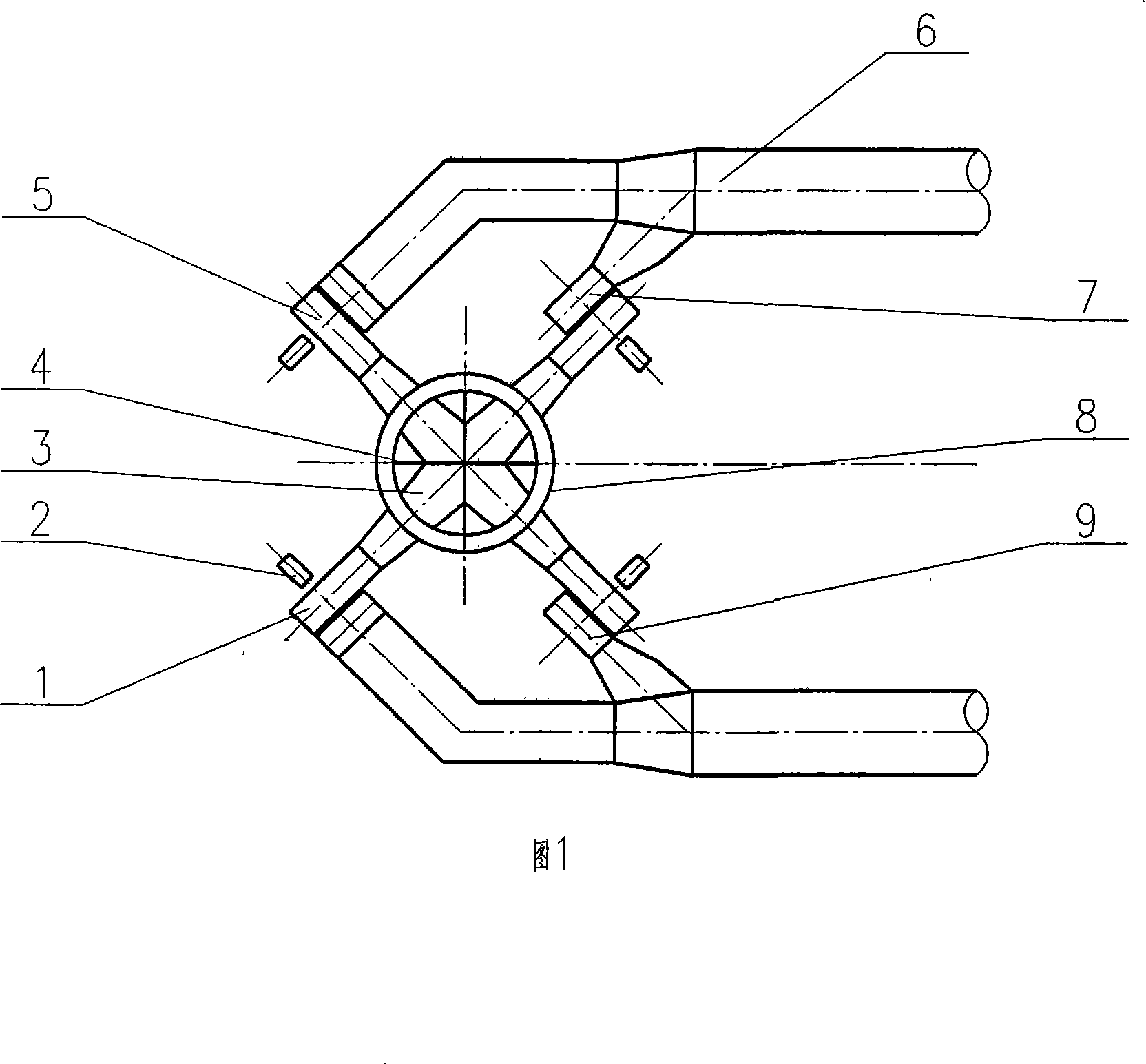

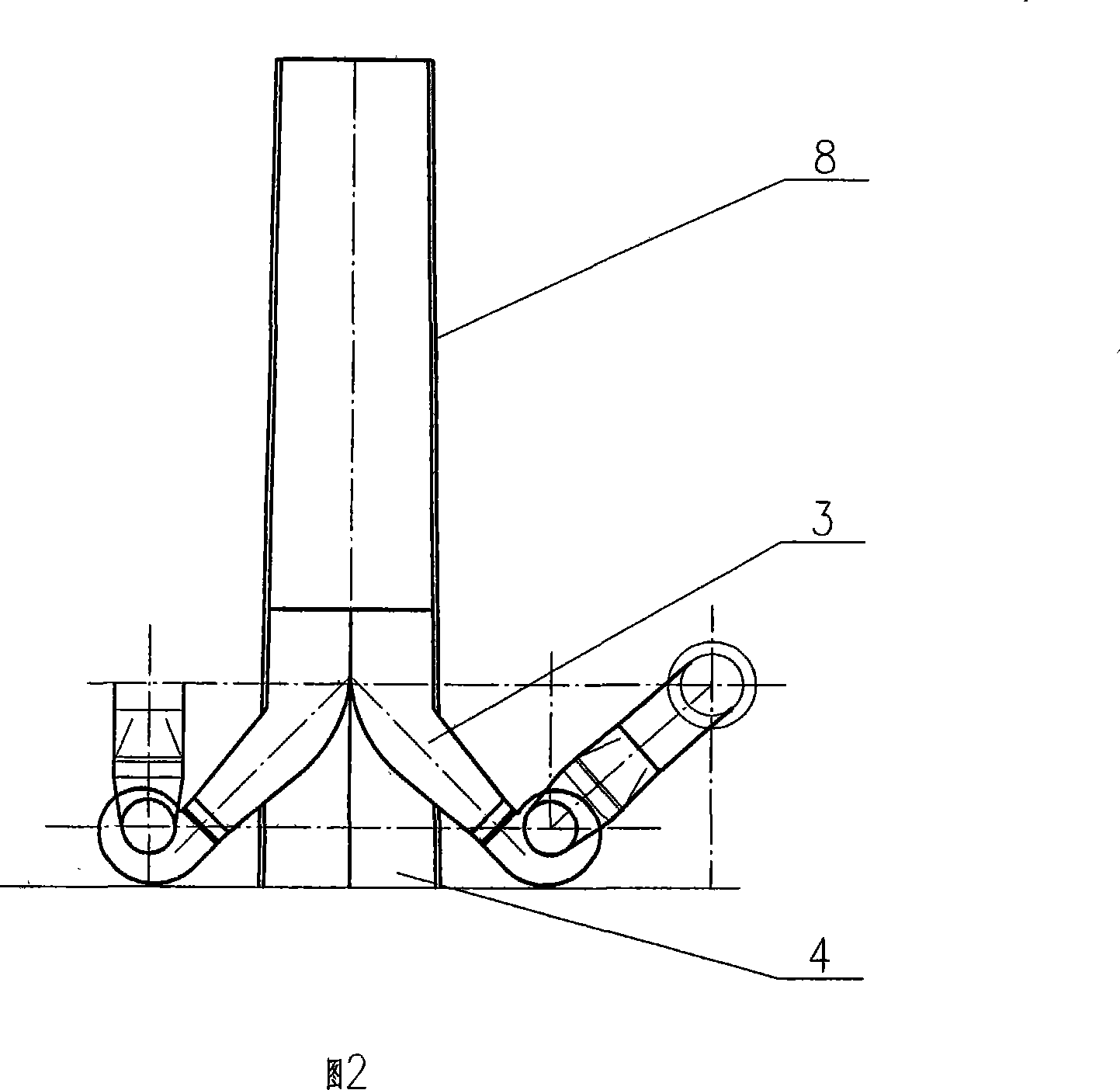

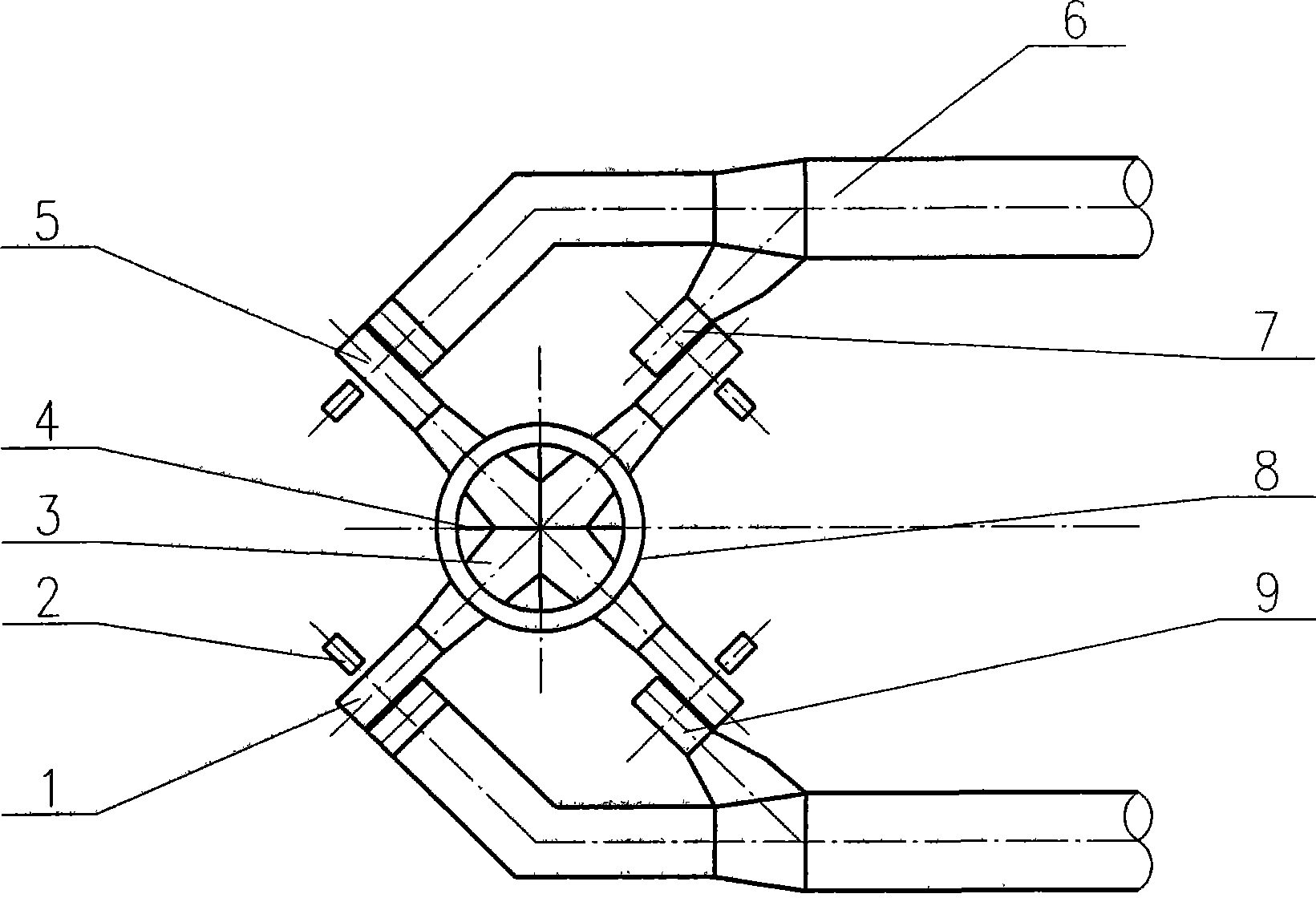

[0021] like figure 1 and figure 2 As shown, the implementation of the present invention is as follows: 4 F-type blowers are respectively: F-type blower 1 turns right into 90° and goes out 45°, F-type blower 5 turns left into 90° and goes out 45°, F-type blower 7 turns right into 45° °out 45°, F-type fans 9 left-handed in 45°out 45°, F-type fans 1, 4, 7, and 9 are evenly distributed along the circumference of the chimney 8, and the center lines of the air outlets of F-type fans 1, 4, 7, and 9 are aligned Along the center of the chimney 8, four F-type fans are configured at a 90° angle, and the inlets of F-type fans 1 and 4 are configured at 90°. The chimney 8 is provided with a cross-shaped partition 4 and a diversion flue 3 . The flue gas discharged by the fan enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com