Automatic testing and sorting machine for wafer

A technology of automatic testing and sorting machine, which is applied in the direction of semiconductor/solid-state device testing/measurement, sorting, etc. It can solve the problems that the standby time affects the test production capacity, etc., and achieve the effect of ensuring the test quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

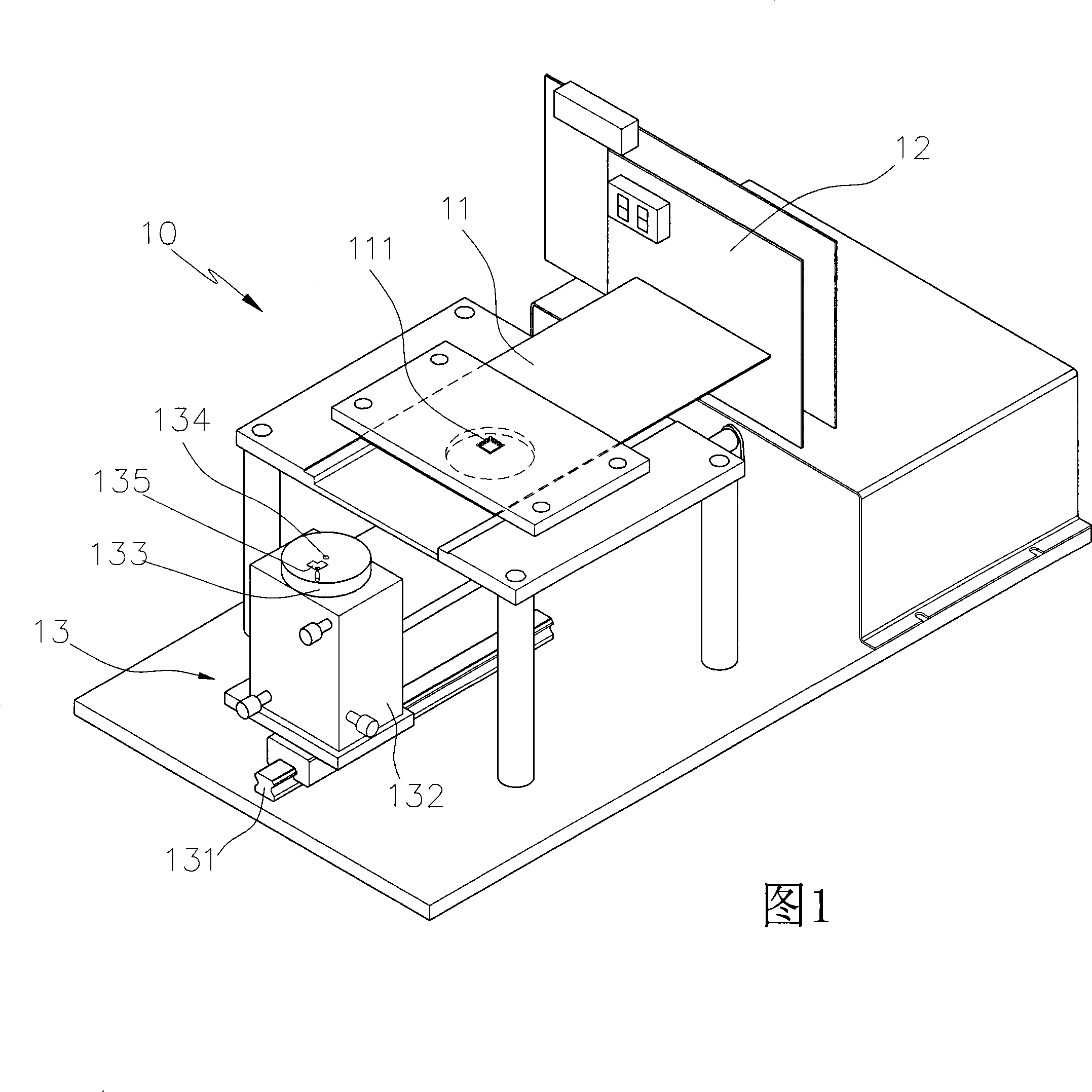

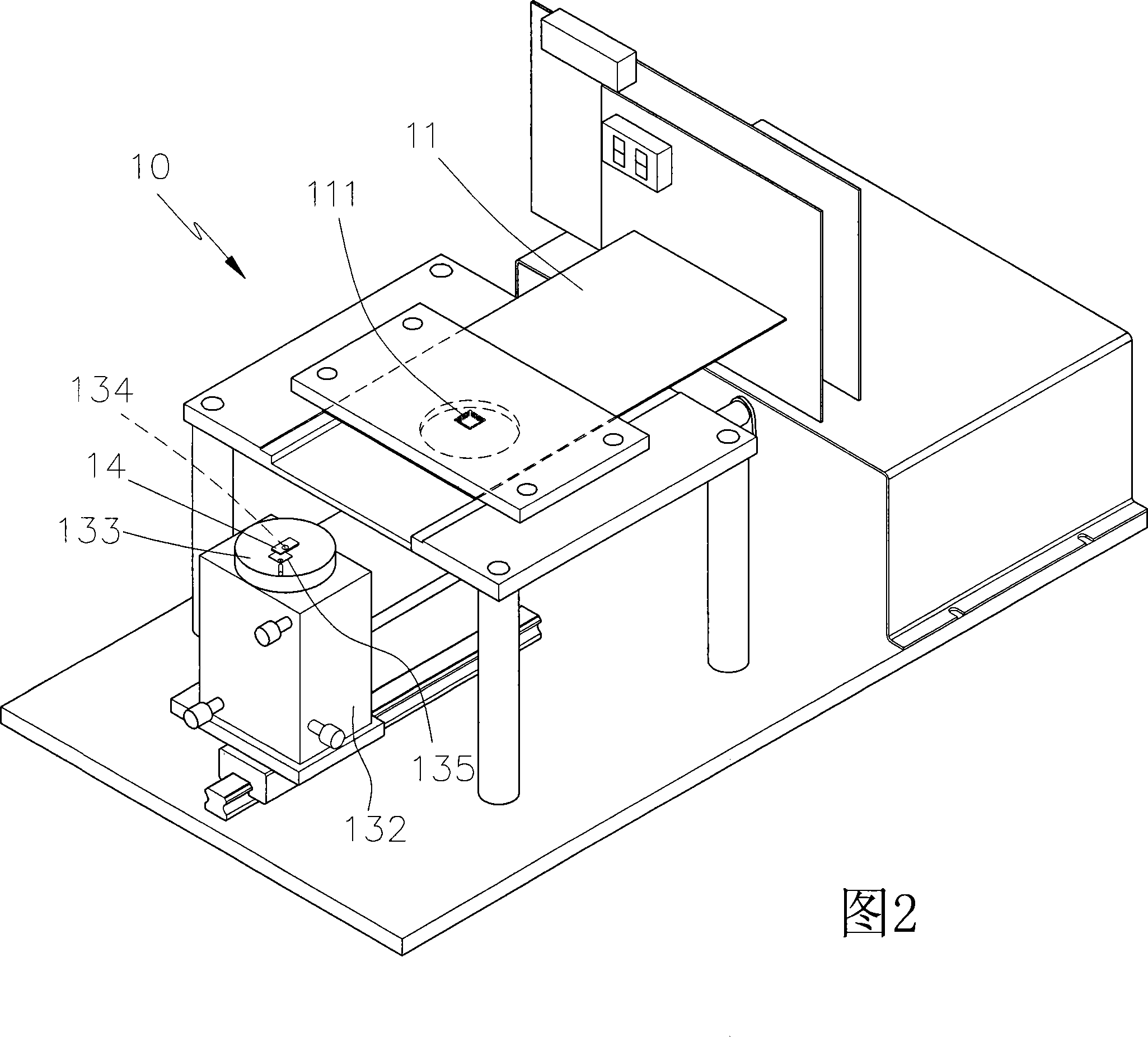

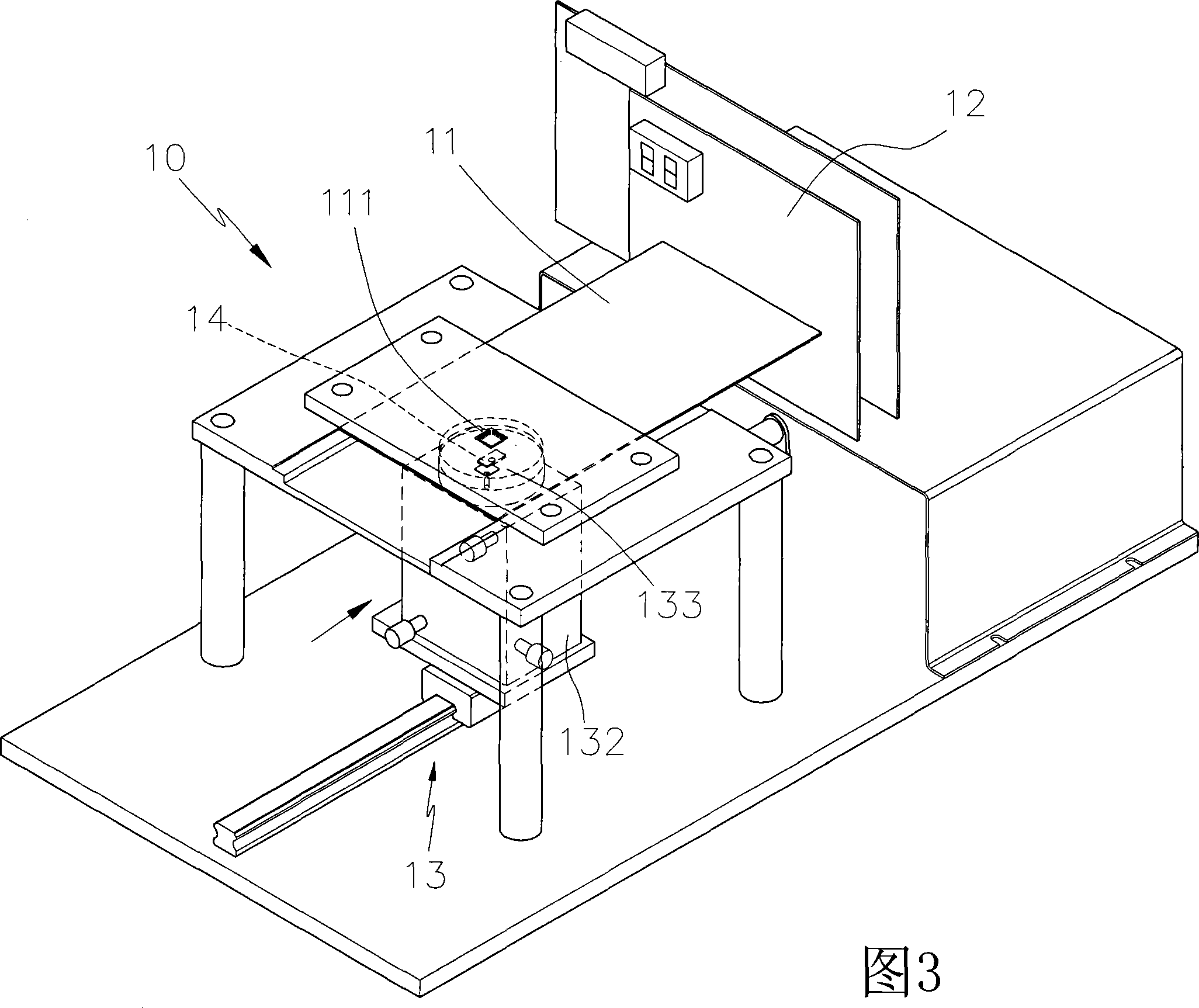

[0033] In order to make your examining committee members have a further understanding of the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows:

[0034] see Figure 5 , the present invention is provided with feeding box 20, the first, the second empty box 23,24 and the first, the second receiving box 29,30 of different grades at the front end of machine table, and described feeding box 20 is liftable For accommodating the material tray 40A bearing the wafer to be tested, the material tray 40A bearing the wafer to be tested can be moved to the first temporary area 21 and the material supply area 22 on the rear side by the supply magazine 20, and the The material area 22 carries out the feeding operation; the first and second empty boxes 23 and 24 can be lifted to accommodate empty material trays 40B and 40C, and the first and second empty boxes 23 and 24 can provide empty material trays 40B and 40C respectively. The second tempor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com