Centrifugal casting device and method of composite hammer head

A technology of centrifugal casting and compound hammer head, which is applied in the direction of grain processing, etc., to achieve the effects of low cost, improved feeding conditions, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

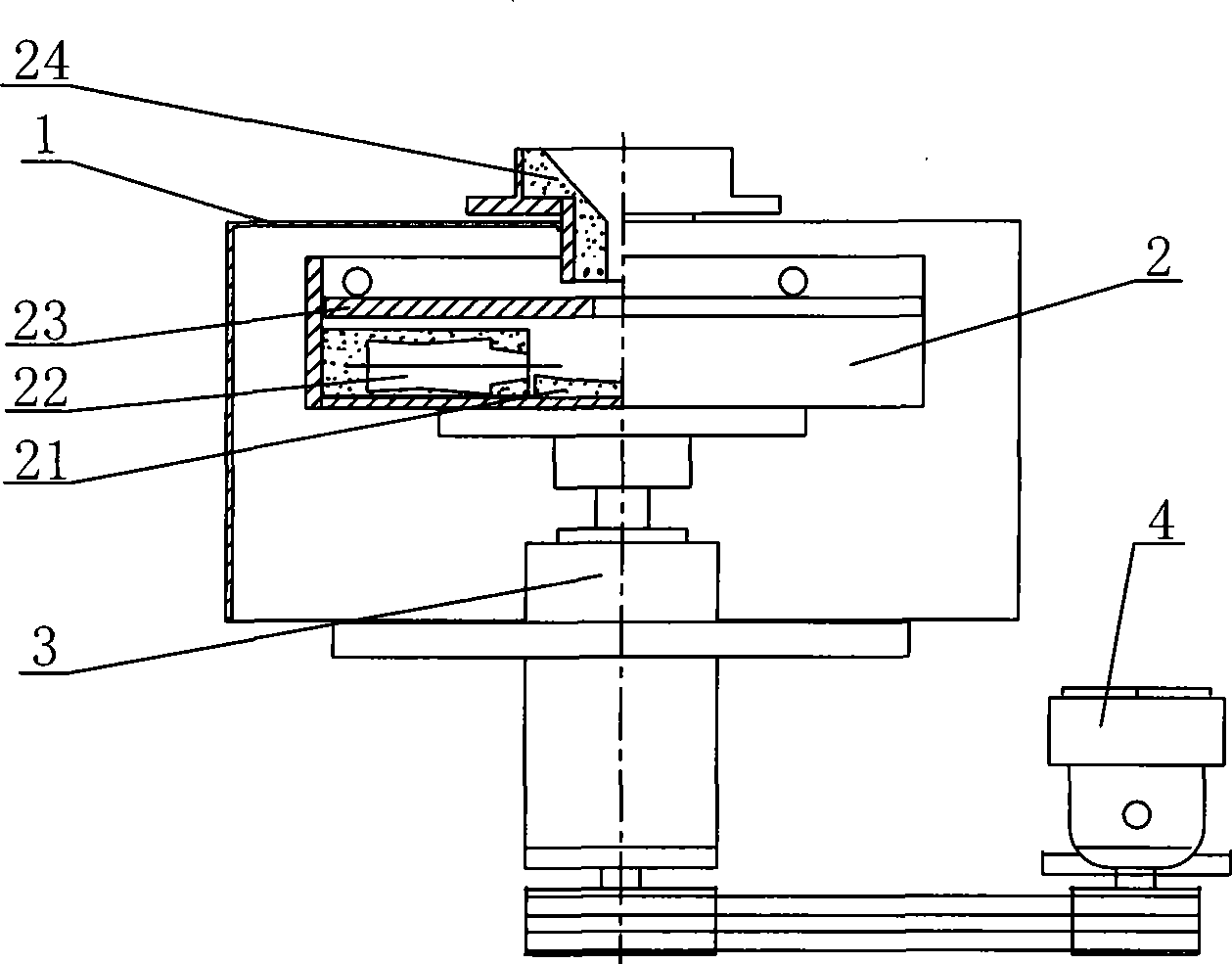

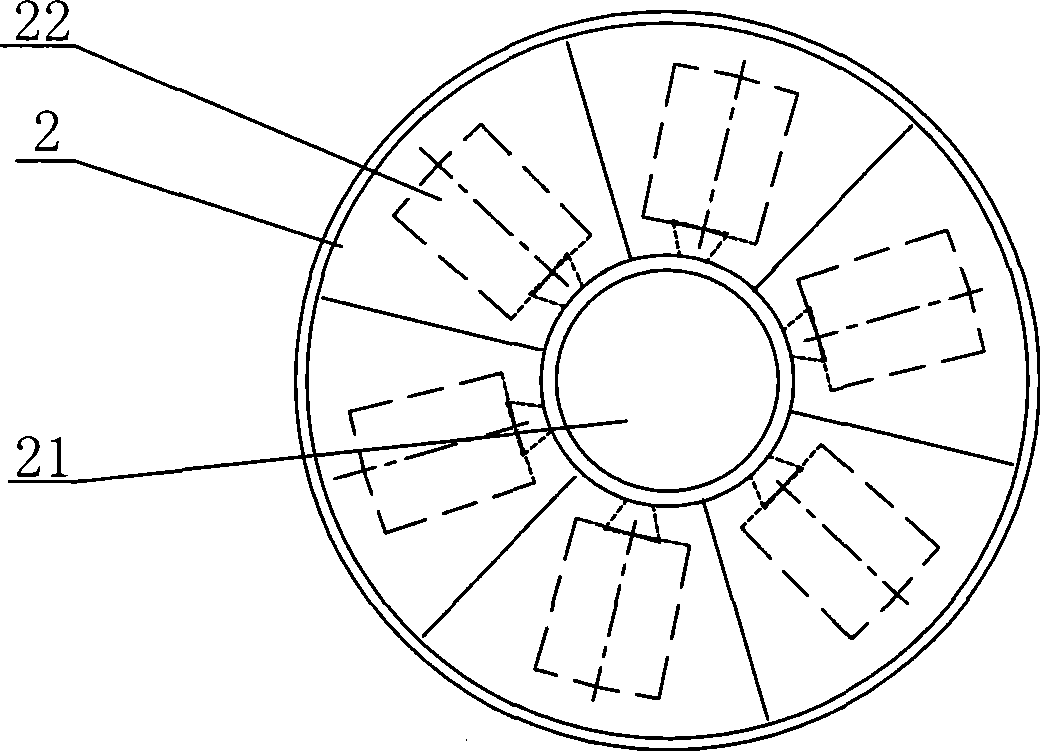

[0014] Such as figure 1 The structure diagram of the compound hammerhead centrifugal casting device of the present invention is shown, including a mold box 2, a rotating shaft 3 is installed in the center of the mold box 2, the other end of the rotating shaft 3 is connected to a variable speed motor 4 through a belt pulley, and a throwing tray is installed at the center of the bottom of the mold box 2 21, such as figure 2 As shown, the inside of the mold box 2 is radially provided with six hammerhead cavities 22 communicating with the throwing tray 21, and is pressed with a cover plate 23, and the top of the mold box 2 is provided with a runner 24 communicating with the throwing tray 21. A protective cover 1 is arranged outside the molding box 2, and the device of the present invention is simple in structure and easy to operate.

[0015] The composite hammer head centrifugal casting method comprises the following steps: pouring the liquid metal I through the sprue 24 onto th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com