Patents

Literature

30results about How to "Improve feed conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

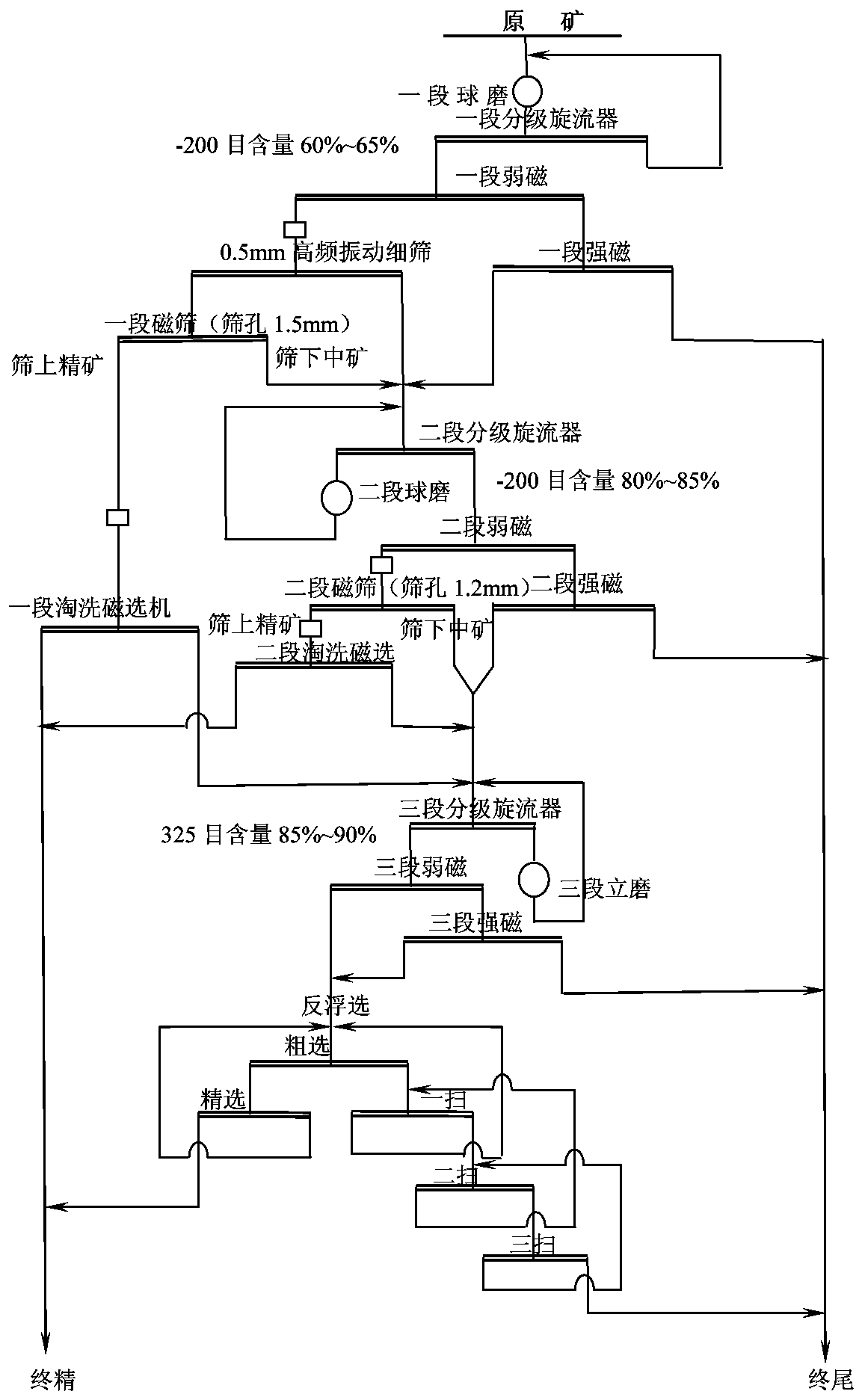

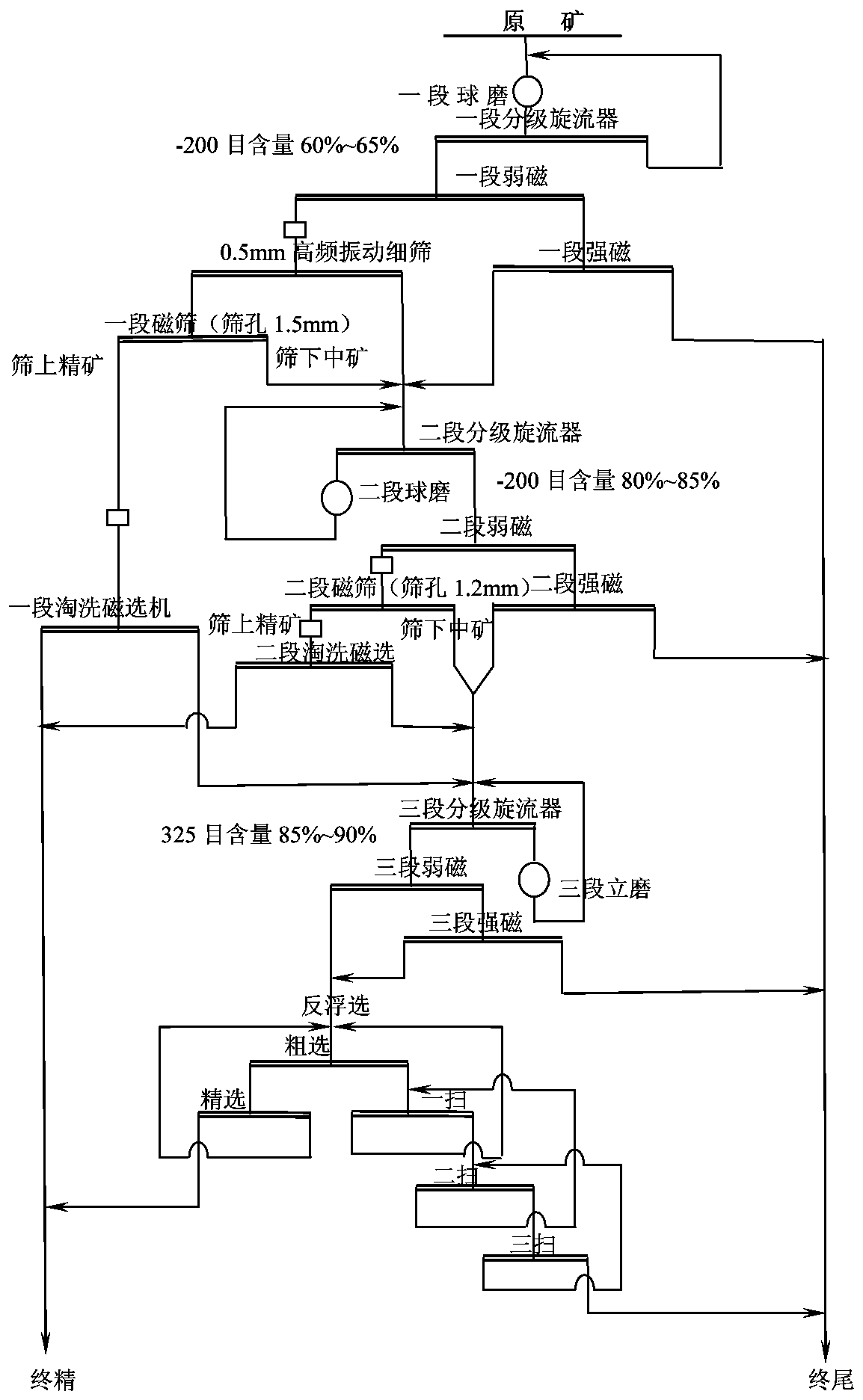

Separation process for magnetic red mixed ore based on iron material disseminated particle size treatment

ActiveCN109351467AReduce grinding energy consumptionReduce overgrindingSolid separationOre concentrateSeparation process

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

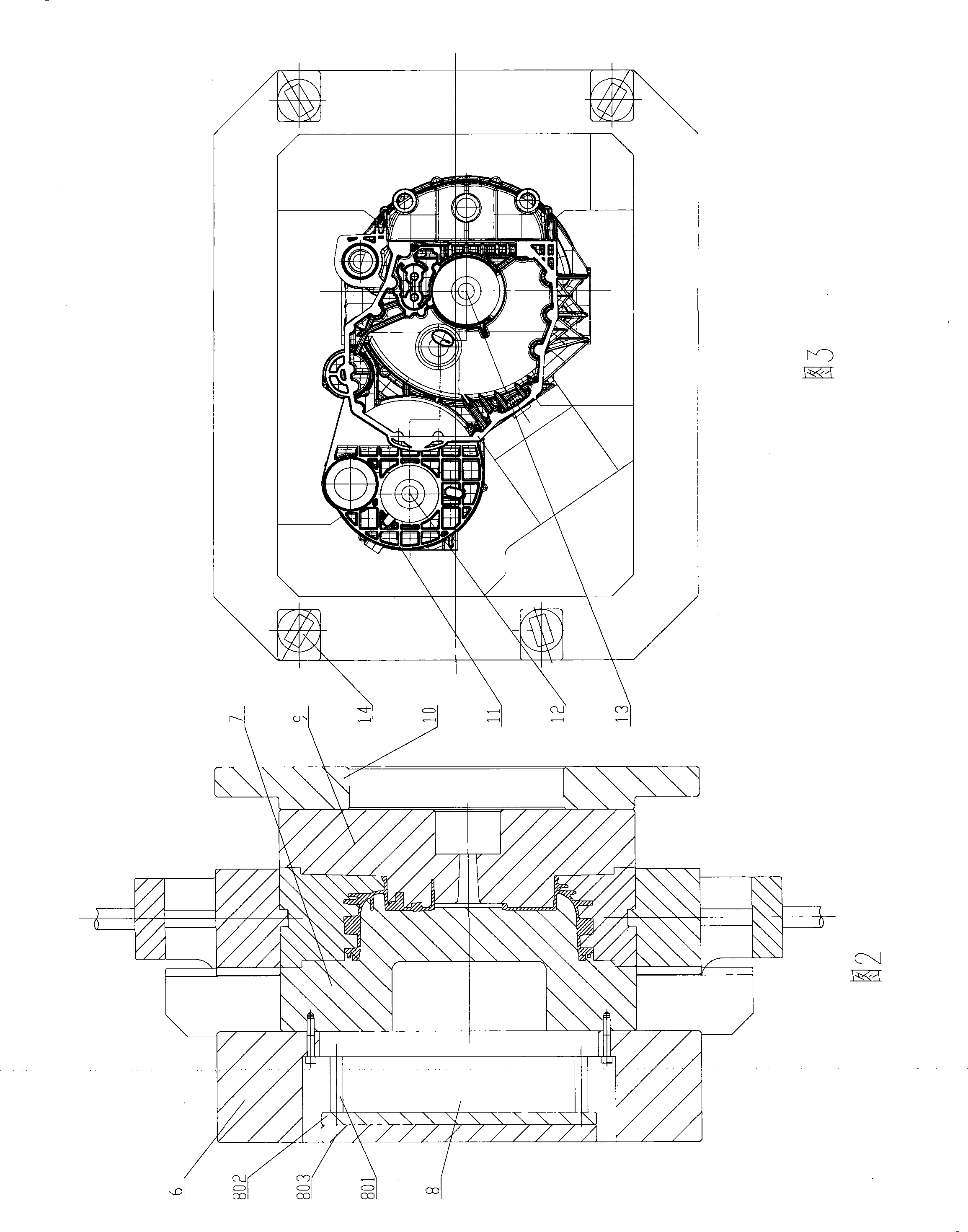

Centrifugal casting method of aluminum alloy impeller

InactiveCN102581249ATissue precisionGuaranteed dimensional accuracyFoundry mouldsFoundry coresImpellerWax

The invention relates to a centrifugal casting method of an aluminum alloy impeller, which solves the problems of high production cost, poor quality of a casting surface and low size precision existing in the existing casting method. The centrifugal casting method of the aluminum alloy impeller comprises the following steps: firstly, preparing an impeller wax mould; secondly, preheating the wax mould; thirdly, processing tools; fourthly, smelting an alloy adopted for the impeller, namely smelting an Al7Si aluminum ingot, adding an Al-5Ti intermediate alloy for smelting, adding a pure Mg block for smelting, and adding an Al-10Sr intermediate alloy for smelting, namely, adding the Al-10Sr intermediate alloy to a graphite crucible, and finally performing degassing refinement after stirring smelting solution in the graphite crucible for 1-5 minutes; and fifthly, centrifugal casting for ensuring the formation and solidification of the alloy smelting solution under the action of the centrifugal force, wherein the solidification time is 3-15 minutes, and finally demoulding and cleaning the casting. The casting method in the invention is used for producing the impeller.

Owner:HARBIN UNIV OF SCI & TECH

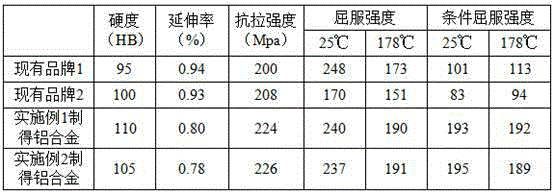

Special aluminum alloy for automobile transmission pump bodies and preparation method thereof

The invention discloses a special aluminum alloy for automobile transmission pump bodies and a preparation method thereof. The aluminum alloy is composed of the following components in percentage by mass: 16.50-17.00% of Si, at most 1.00% of Fe, 0.55-0.60% of Mg, 4.30-4.60% of Cu, at most 0.45% of Mn, 0.50-1.30% of Zn, at most 0.09% of Ni, at most 0.09% of Ti, at most 0.09% of Pb, at most 0.003% of Ca, at most 0.002% of Na, 0.006-0.015% of P and the balance of Al. The preparation method comprises the following steps: smelting primary aluminum ingot, silicon, pure metal copper, pure metal magnesium, AlFe10 interalloy, zinc part, aluminum-phosphorus alloy and phosphorus-rich alloy, refining, standing and casting. The aluminum alloy material is specially used for preparing automobile transmission pump bodies, has the advantages of higher wear resistance, higher tensile strength, higher thermal cracking resistance and high mold-filling capacity, and can prolong the service life of the automobile transmission pump bodies.

Owner:GUANGZHOU LIZHONG JINSHAN ALLOY

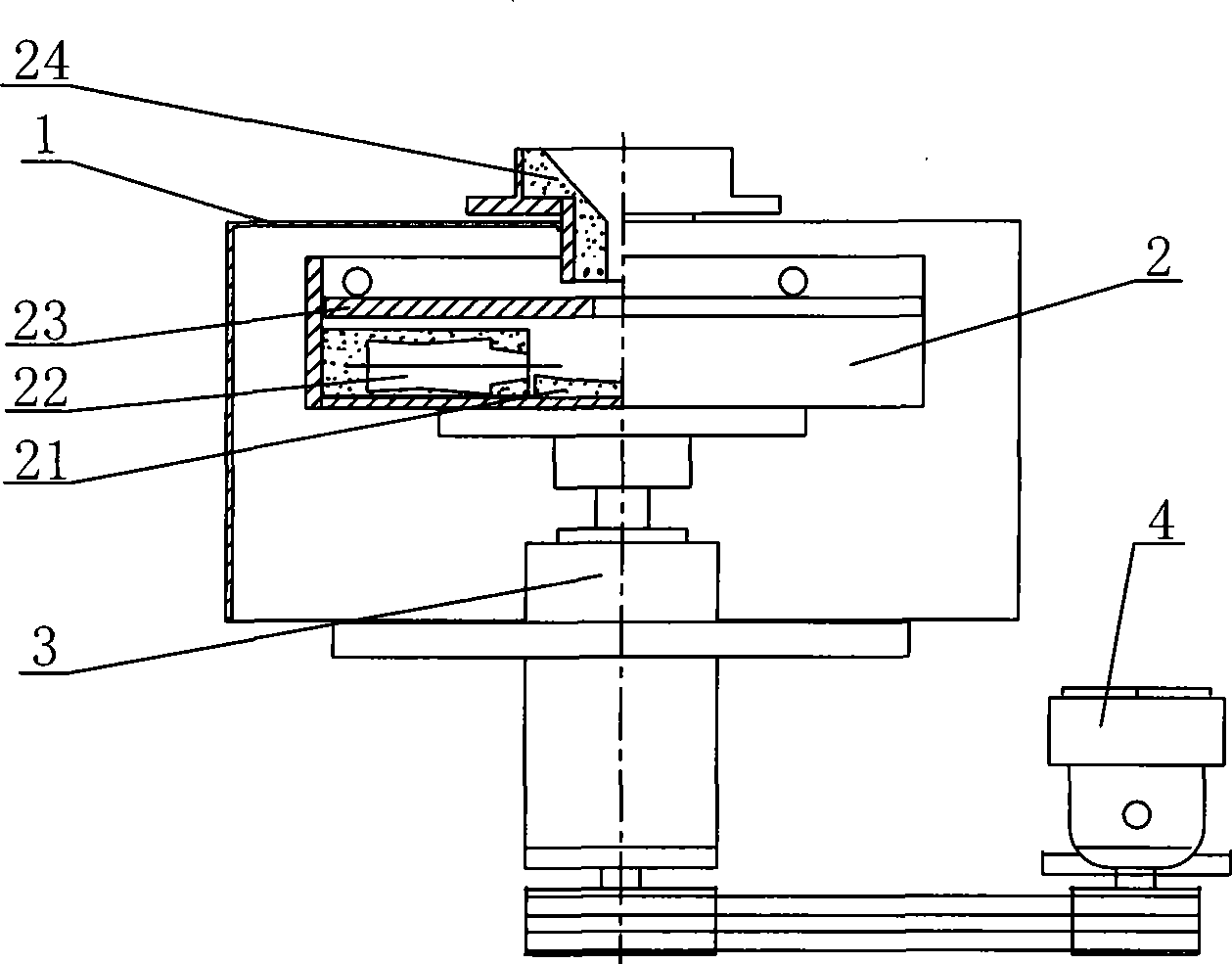

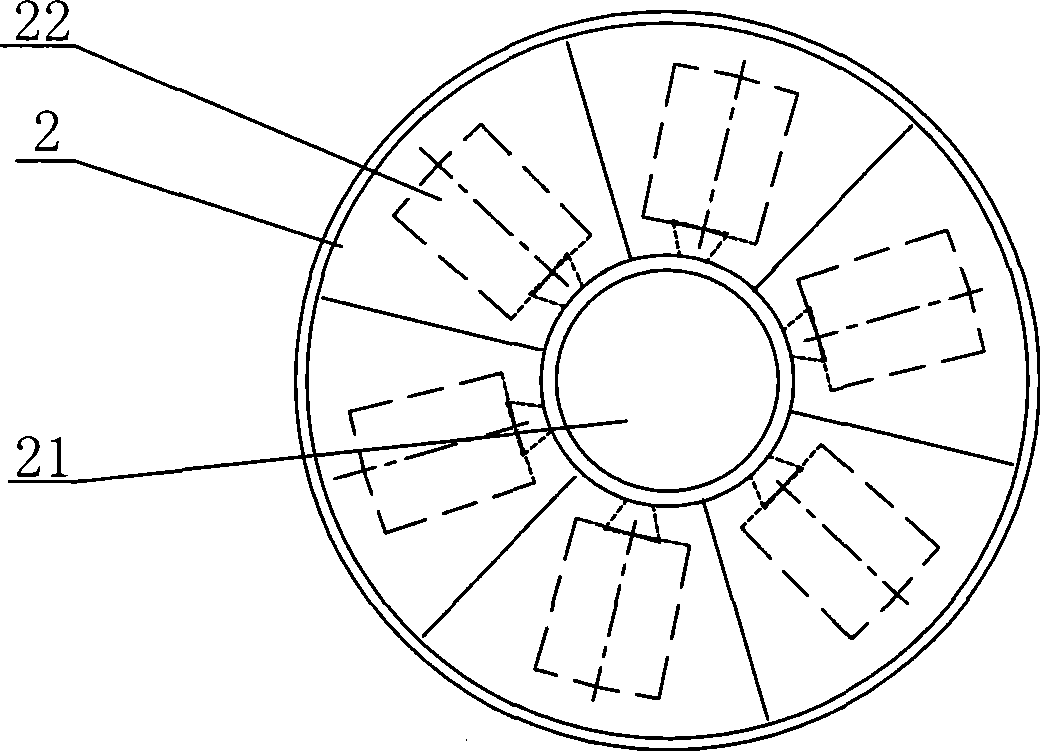

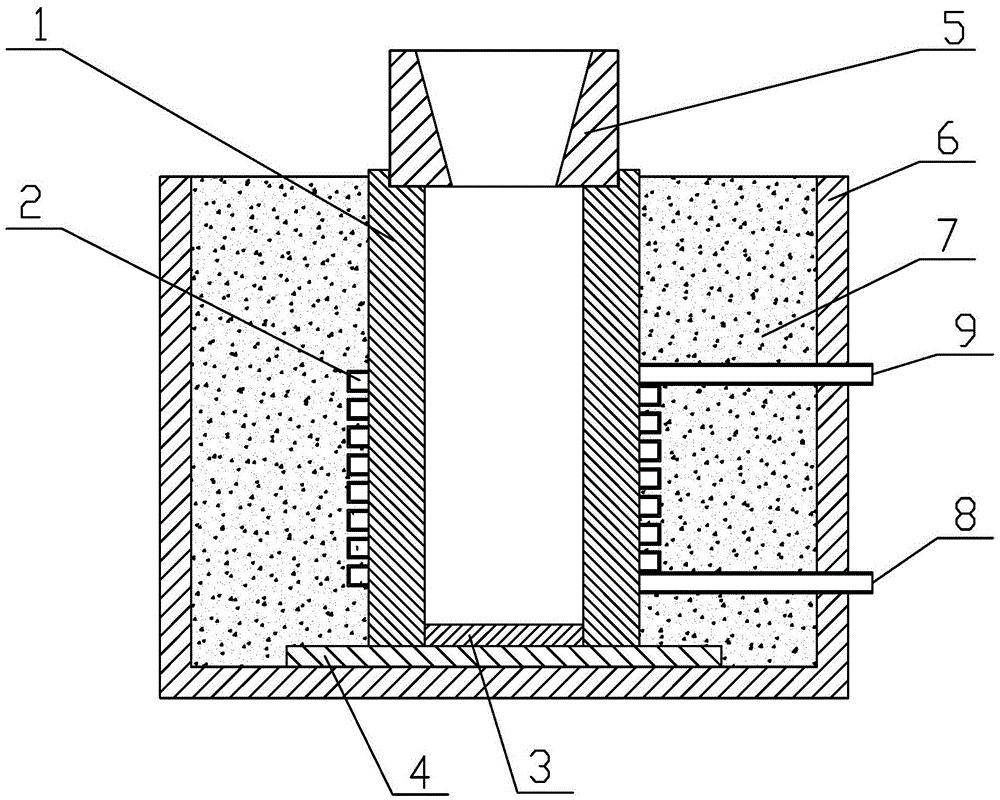

Centrifugal casting device and method of composite hammer head

InactiveCN101412084AImprove cavity filling abilityEasy dischargeGrain treatmentsCentrifugal forceMolten metal

The invention discloses a compound hammerhead centrifugal casting device and a centrifugal casting method. The device comprises a casting box, a rotary shaft is inserted in the center of the casting box, the other end of the rotary shaft is connected with a variable speed motor by a belt, the center of the bottom part of the casting box is provided with a material dumping disk, an inner part of the casting box is provided with a plurality of hammerhead die cavities communicated with the material dumping disk along the radial direction, and a top part of the casting box is provided with a casting channel communicated with the material dumping disk; the molten metal I is poured on the material dumping disk in the casting box by the casting channel, the material dumping disk rotates along with a rotary shaft, the molten metal I on the material dumping disk is evenly dumped in the hammerhead die cavities under the centrifugal action to be solidified, the molten metal II is poured in the casting box, and the steps are repeated to complete the preparation of the hammerhead. The device is simple in structure and low in cost, and the preparation method is simple and easy in operation and good in effect.

Owner:金培良

Biological organic fertilizer and method for preparing the biological organic fertilizer by fermentation of municipal sludge

InactiveCN102476965AFast compostingTake advantage ofBio-organic fraction processingOrganic fertiliser preparationSludgeOrganic fertilizer

The invention relates to the field of biotechnology, in particular to a good-quality biological organic fertilizer and method for preparing the good-quality biological organic fertilizer by fermentation of municipal sludge. The method comprises well mixing sludge 55-65wt%, conditioner 0.5-0.75wt%, straw 25-35wt%, humic acid 5-15% and decomposing microbial inoculums 0.01-0.02wt% to serve as a fermentation material with a water content 50-60%; heaping the fermentation material at 10 DEG C. for 2-3 days to allow the fermentation material temperature to rise to 55-65 DEG C. while turning for 1-2 times every day and controlling the fermentation temperature at 55-60 DEG C. for 5-7 days; and further decomposing for 3-5 days when the heap fermentation material is cooled to 30-40 DEG C. The inventive method has simple process and low cost, and can produce a biological organic fertilizer with good fertilizer effects and solve the problem that the long-term stored municipal sludge can pollute the environments.

Owner:LIAONING TIANRUN BIOLOGICAL TECH CO LTD

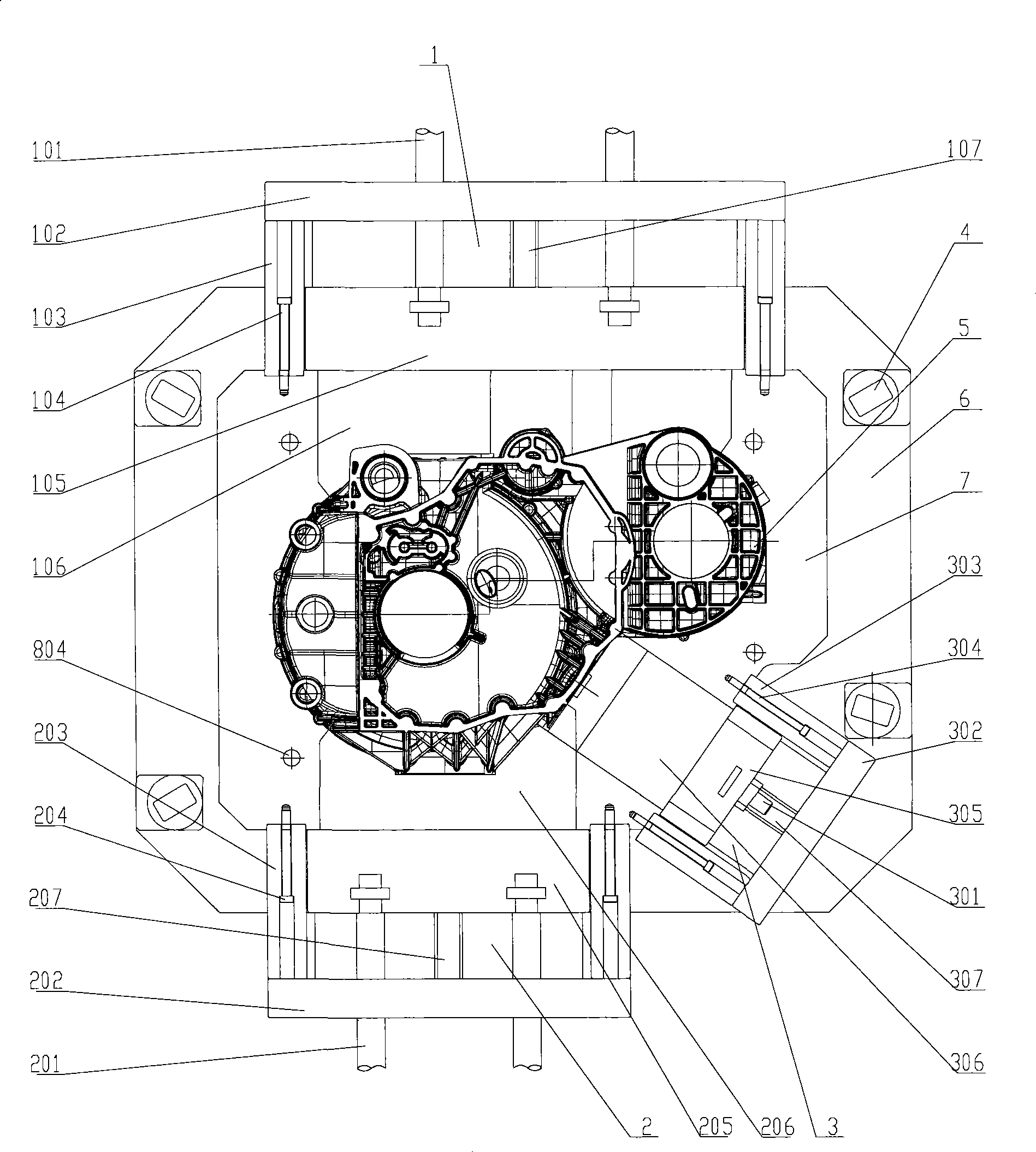

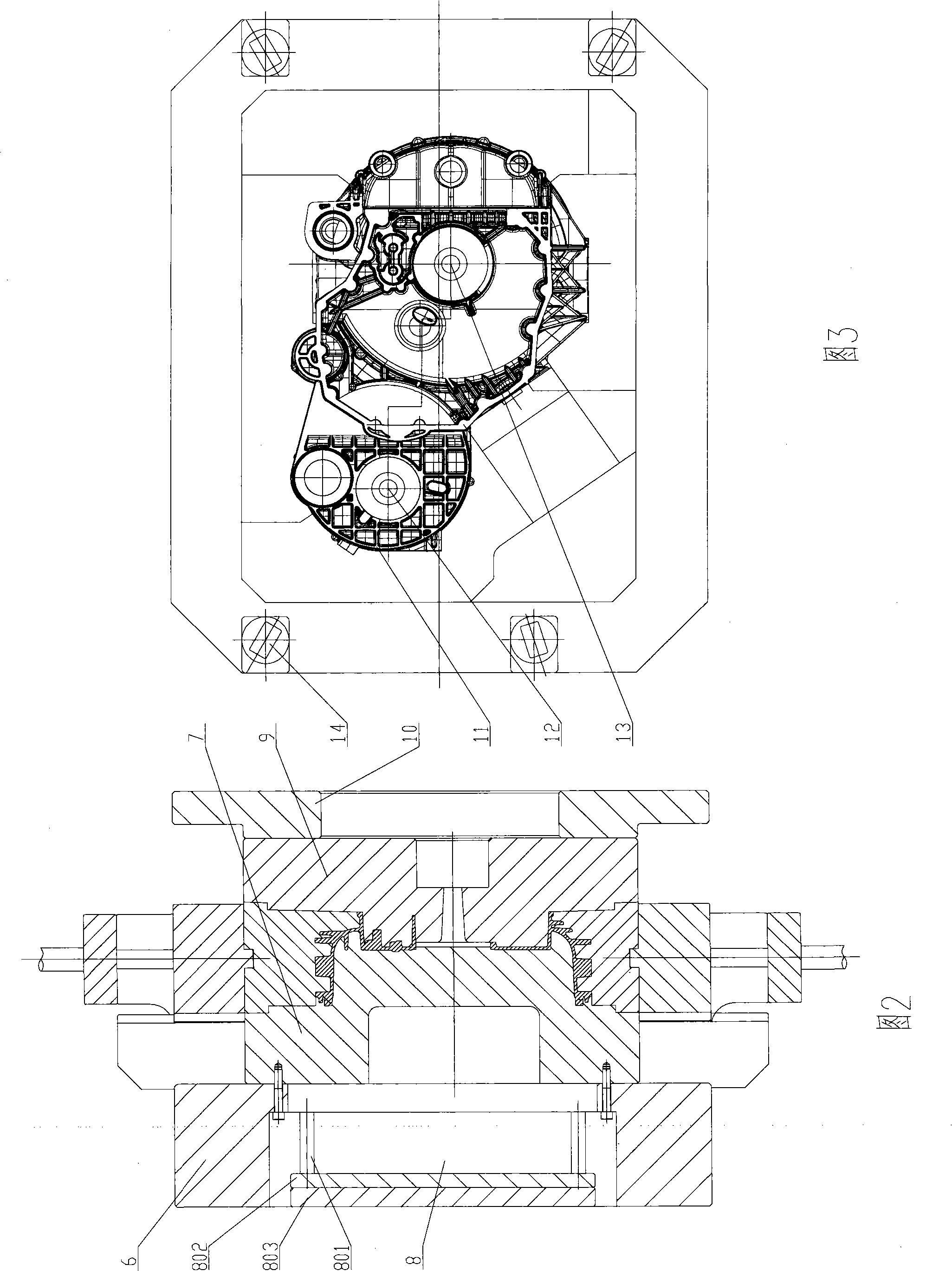

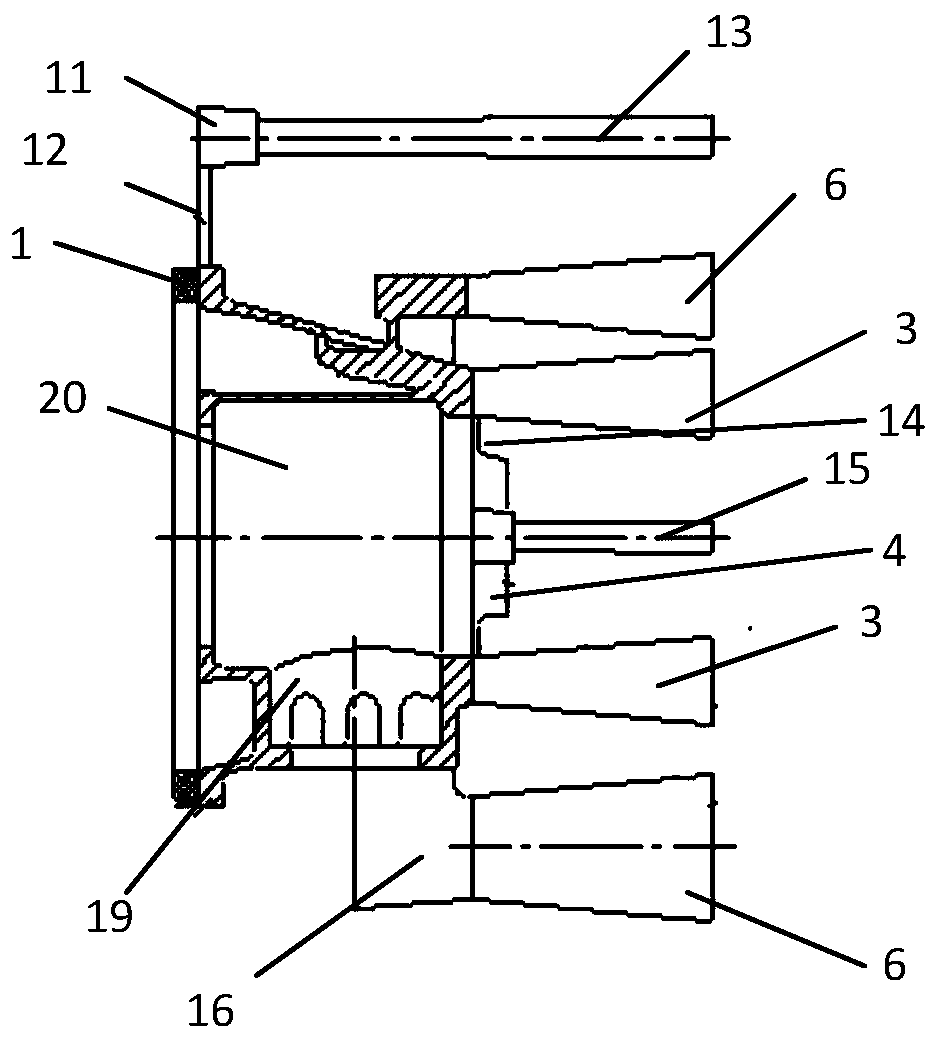

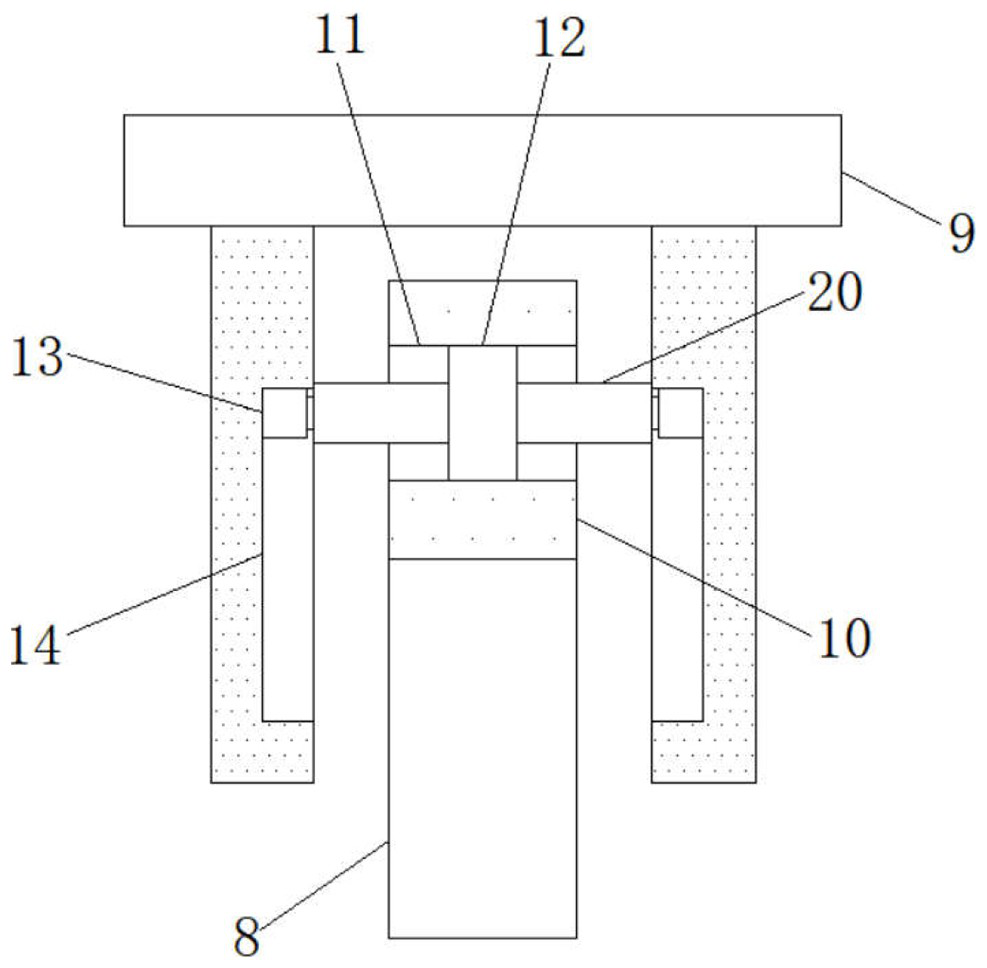

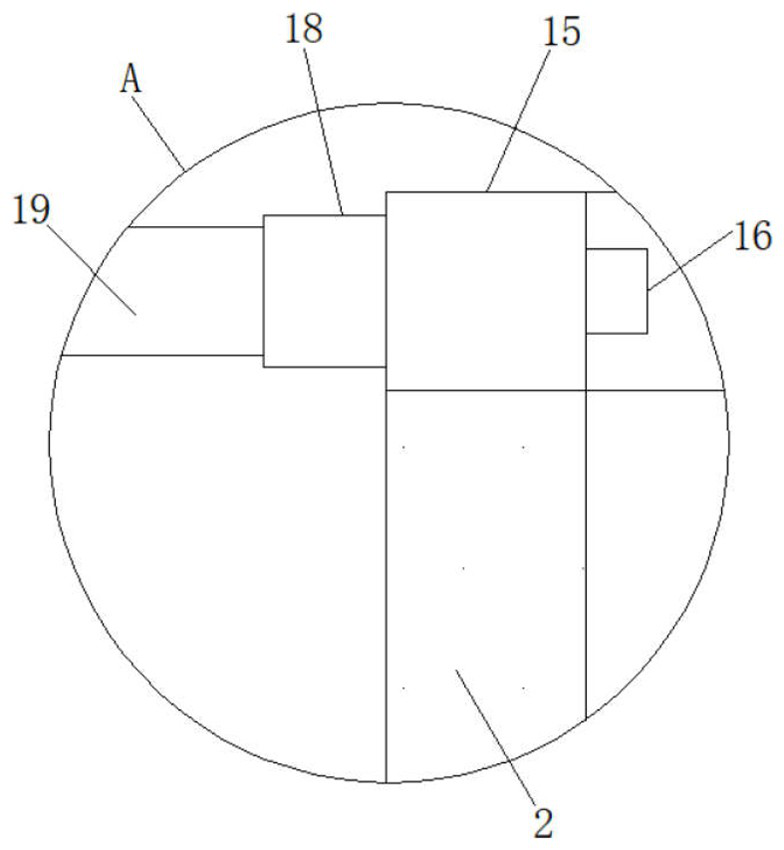

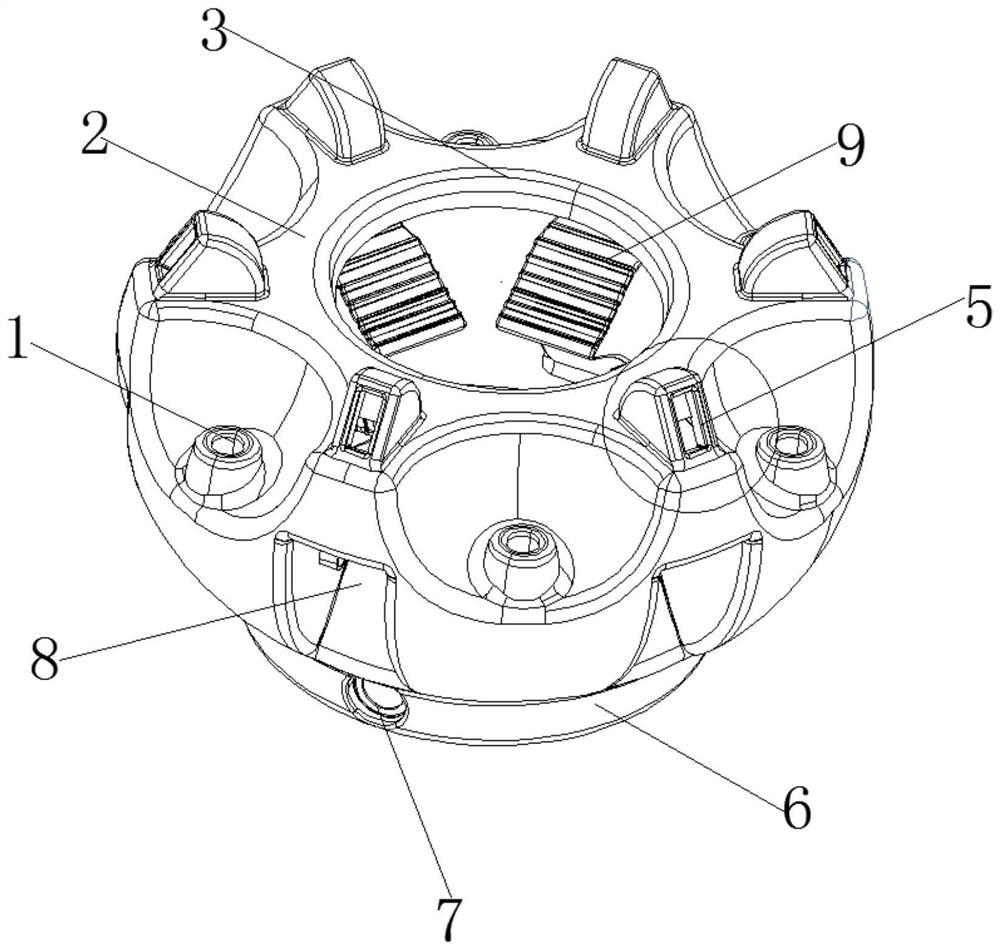

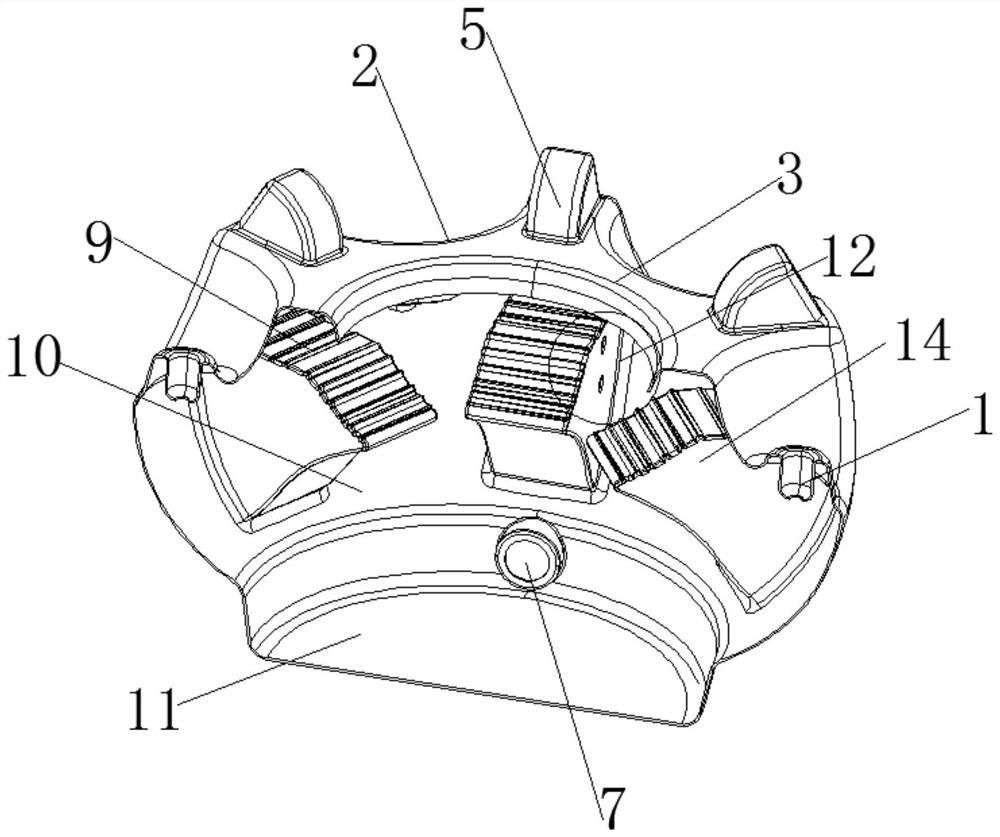

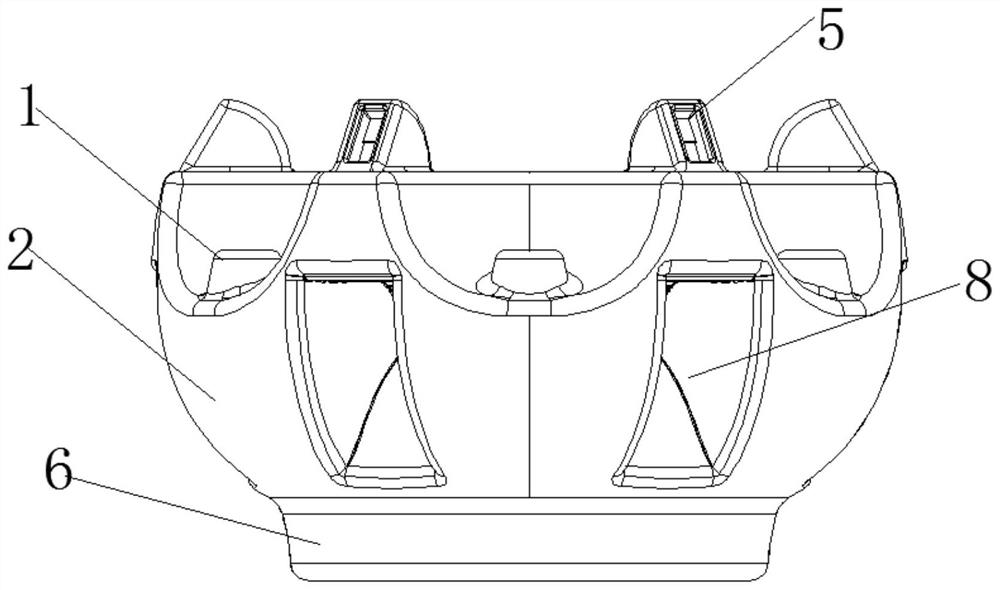

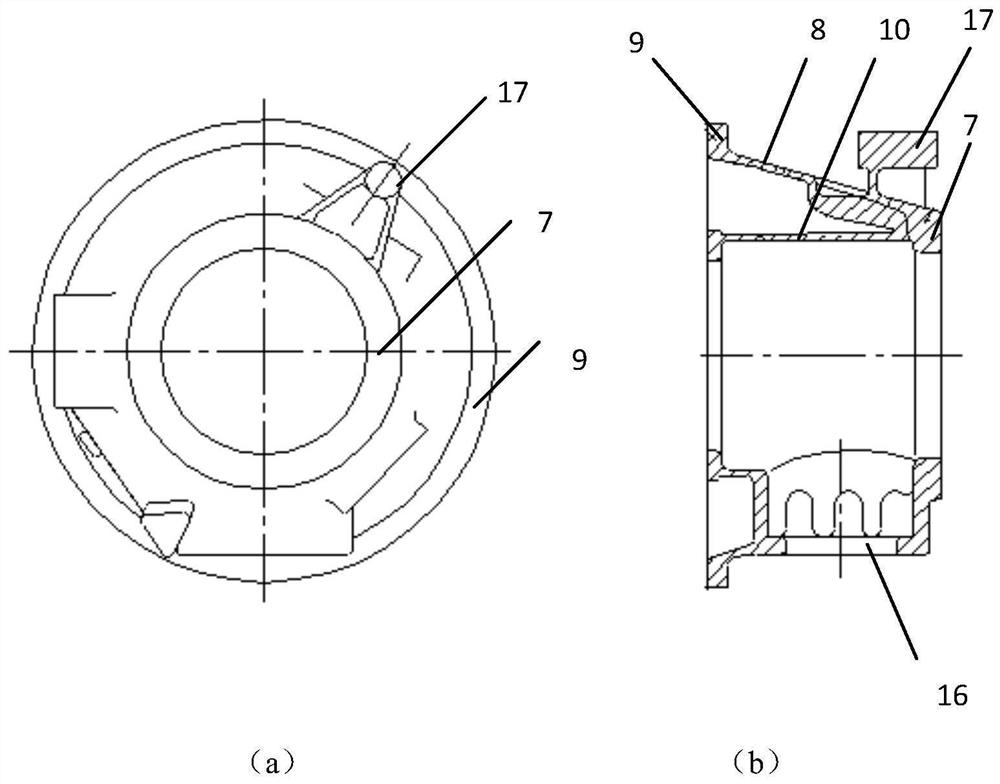

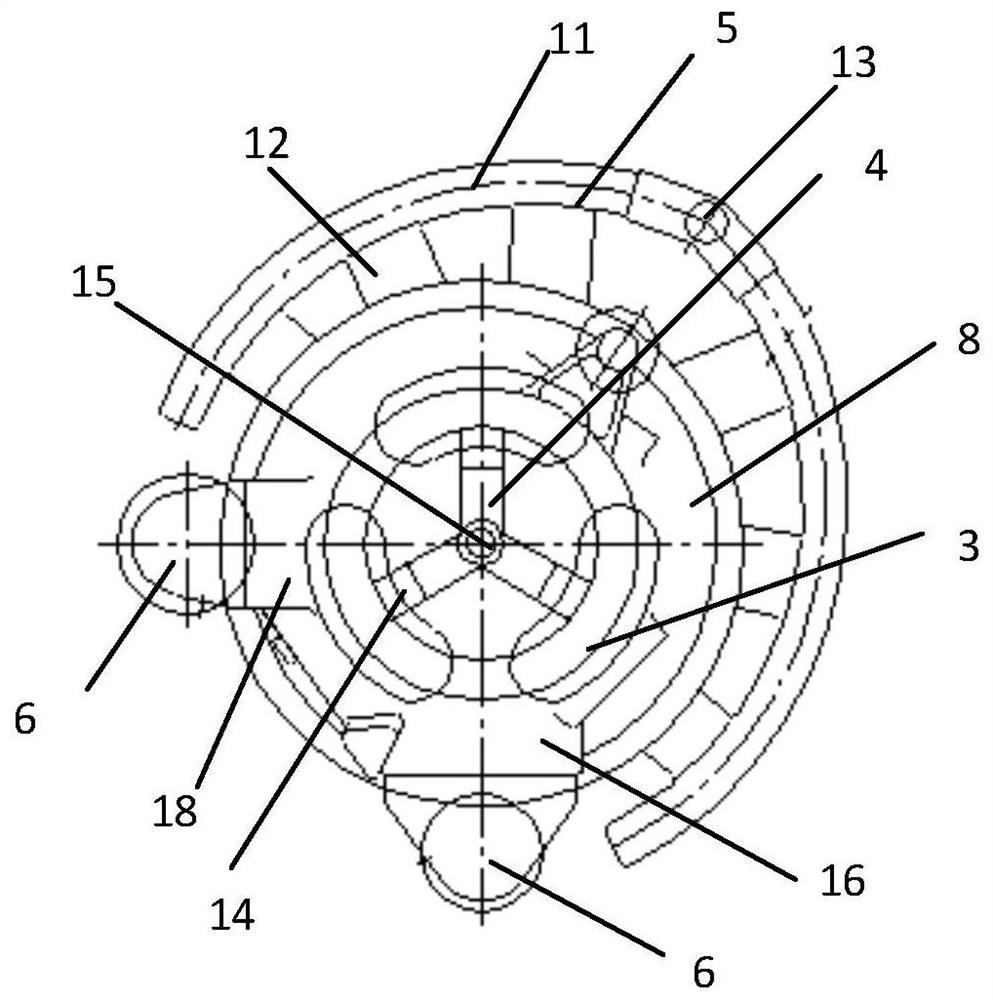

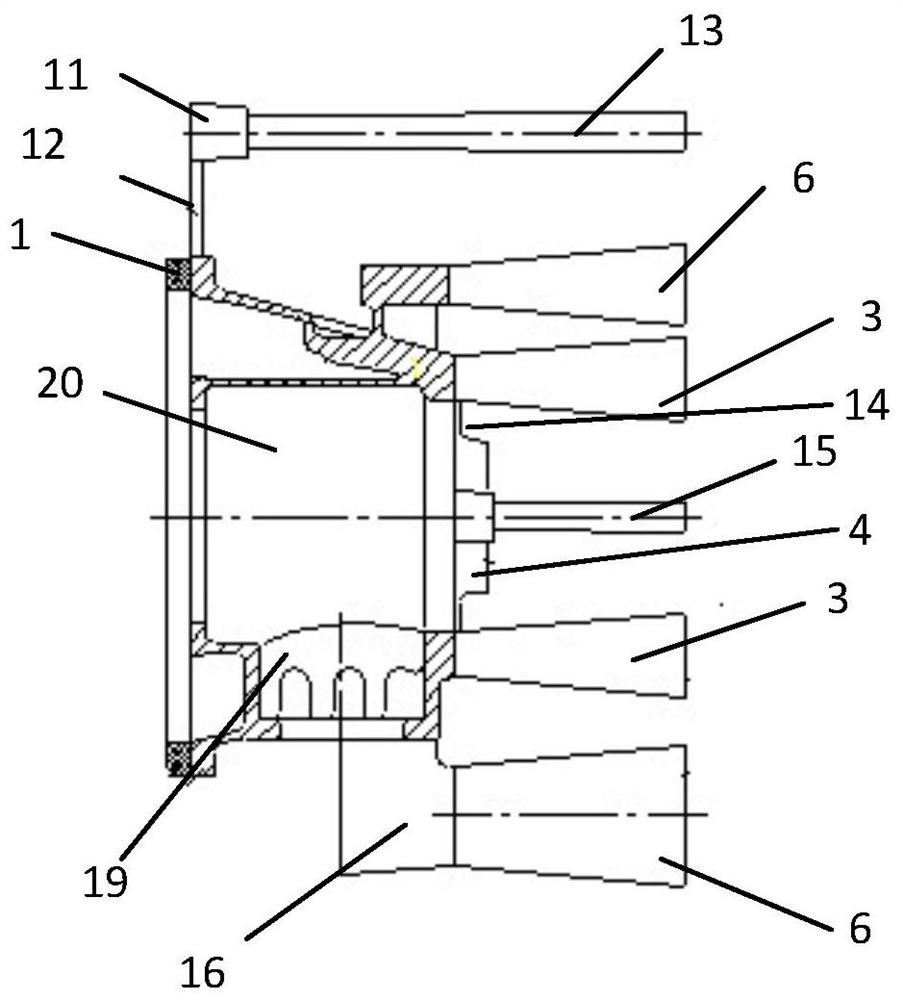

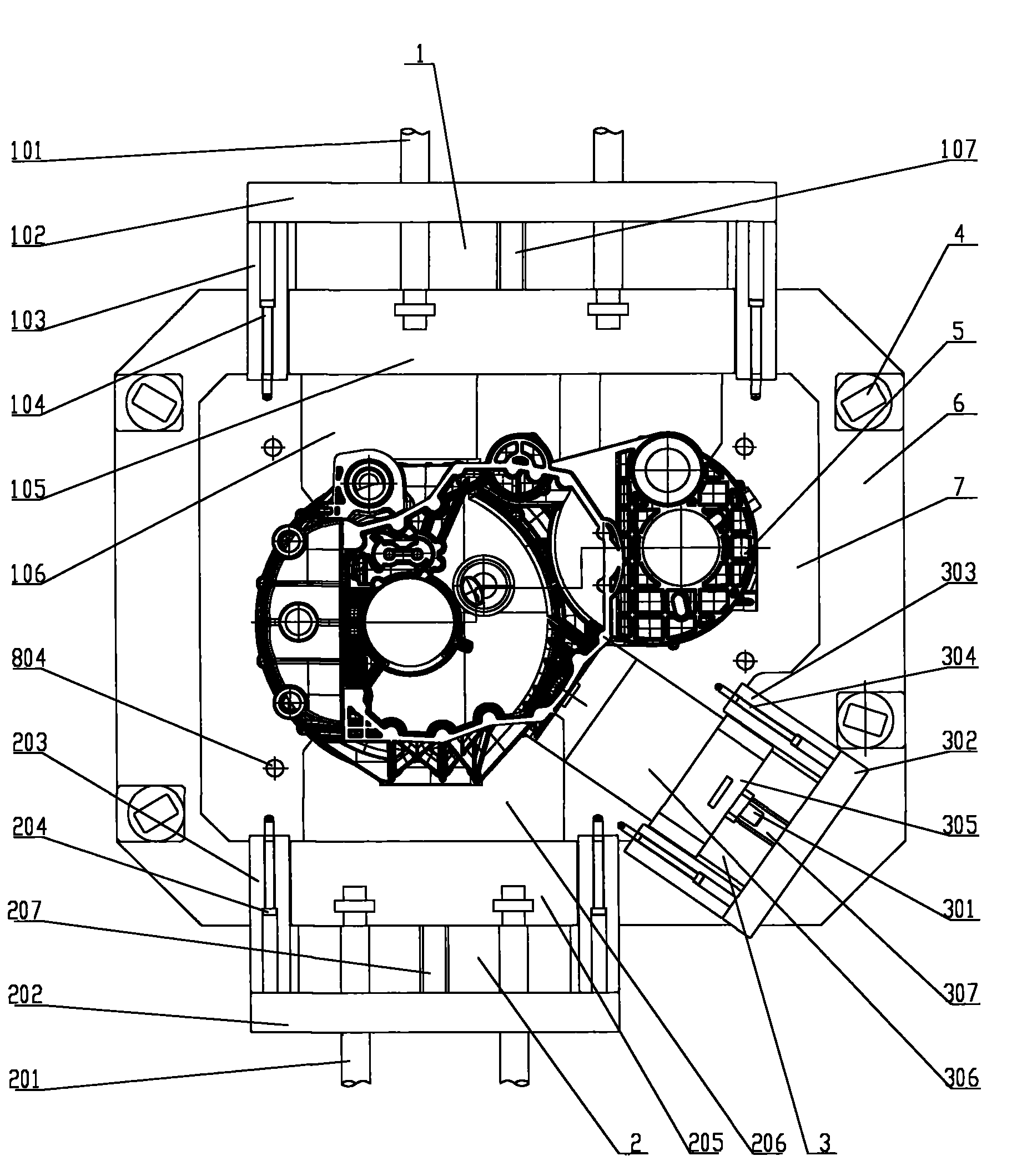

Casting technique of heavy duty trucks gear box and die

The invention relates to a forging process for a heavy truck gearbox and a die, which are used for forging the heavy truck gearbox. The forging process is characterized by adopting low-pressure forging; the forging die consists of an upper die and a lower die, wherein the upper die comprises an upper module, an upper die carrier, core pulling mechanisms, a composite positioning sleeve and a casting ejecting and resetting mechanism; the upper die carrier is connected with a machine tool; the number of the core pulling mechanisms is three; the lower die comprises a lower module, a lower die carrier and a composite positioning pin; a pouring head I (12) and a pouring head II (13) are arranged in the lower module; and the lower die carrier is connected with the machine tool. The forging process and the die do not need expensive investment, and can produce casting products according with requirements; the casting has no riser head, the pouring heads are small, and the utilization rate of the molten metal is high; the arrangement of the double pouring heads effectively shortens the filling stroke of the molten metal, and improves the feeding conditions when the casting is solidified; the casting is solidified under definite pressure to increase the consistency of casting tissues and improve the quality of the casting; and the production efficiency is high, and few auxiliary materials are consumed.

Owner:NINGBO HELI TECH CO LTD

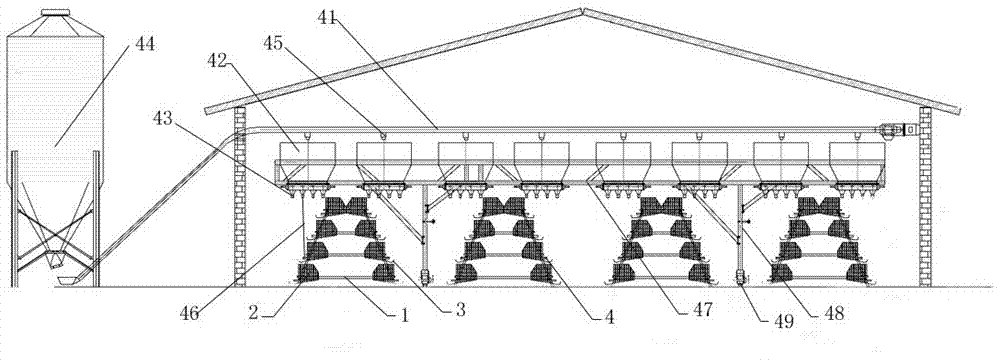

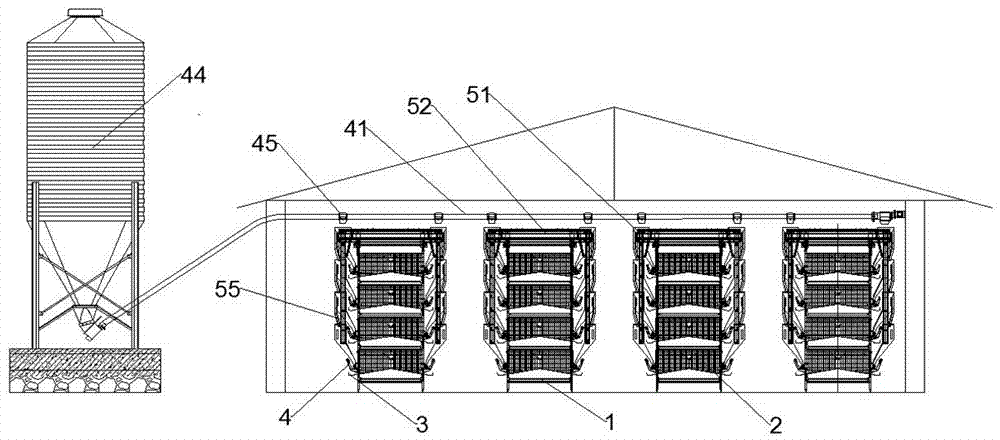

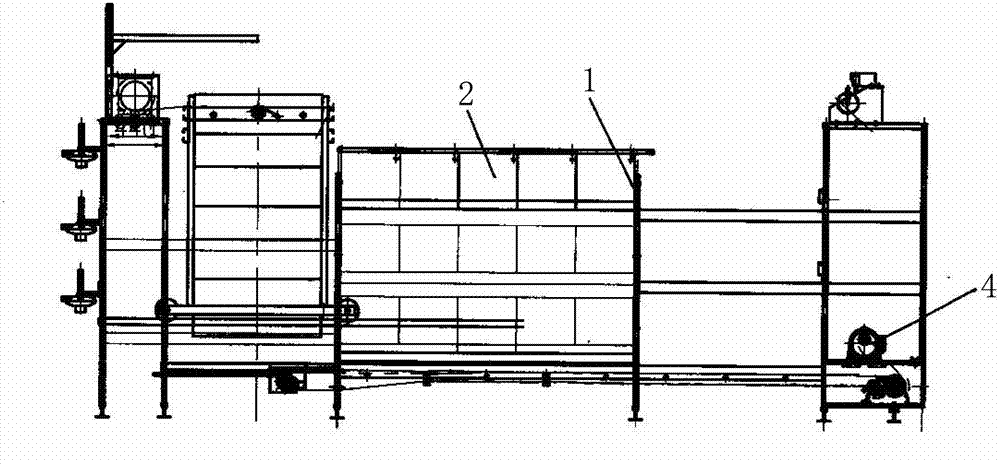

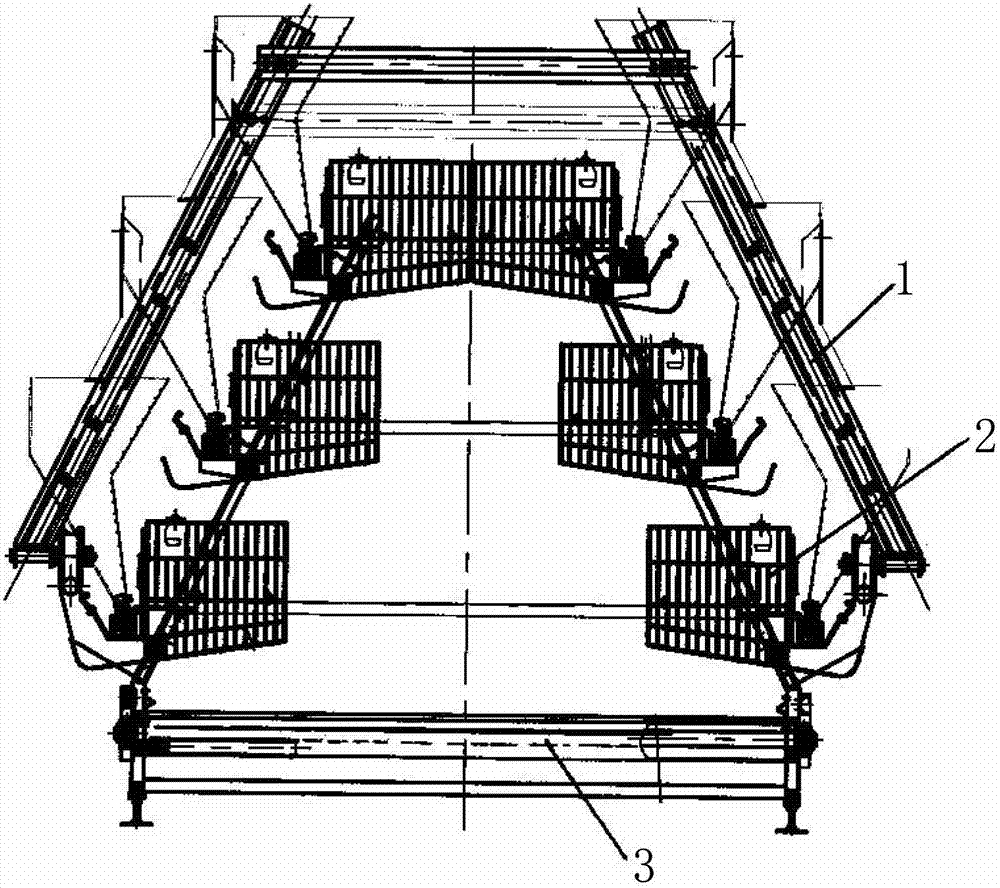

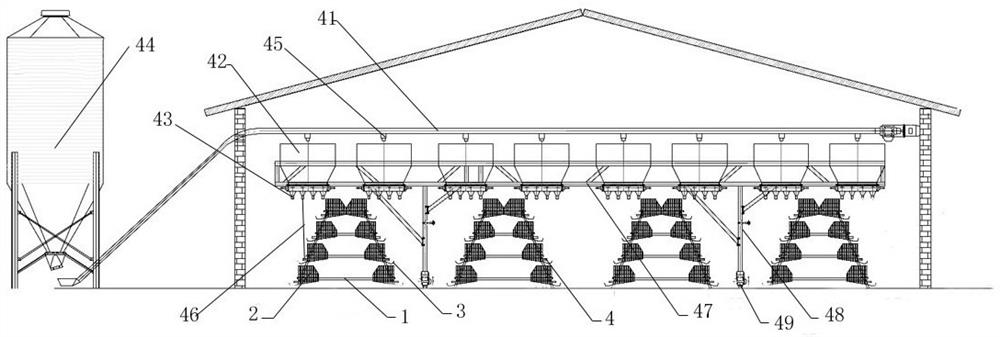

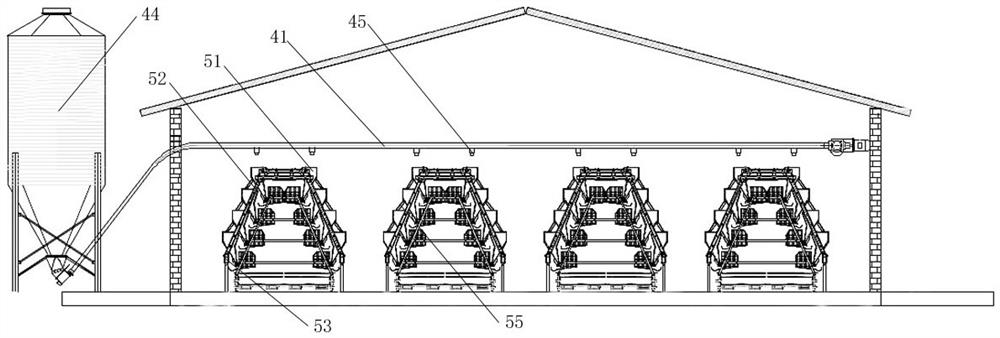

Stepped laying hen cage

ActiveCN106922564AReduce labor intensityReduce morbidityBird housingsAutomatic controlWater drinking

The invention discloses a stepped laying hen cage, which comprises a laying hen cage main body, a feeding device, an egg collecting device, water drinking devices and a manure cleaning device, wherein the laying hen cage main body comprises a hen cage frame and more than four hen cage bodies; the hen cage frame is a trapezoidal frame; the hen cage bodies are symmetrically arranged at two sides of the hen cage frame to form a stepped structure; an egg tray is arranged at the lower part of each hen cage body; a trough is arranged in the outer side of each hen cage body; the feeding device is arranged above the troughs; the egg collecting device is arranged on the side surface of the laying hen cage main body and connected with the egg trays; the water drinking device is arranged in each hen cage body; and the manure cleaning device is arranged at the lower part of the laying hen cage main body. The stepped laying hen cage is high in automatic degree, full-automatic control on loading, feeding, water drinking, manure cleaning, egg collecting and environment is achieved, the labor intensity is greatly reduced and the labor cost is saved.

Owner:河南金牧人机械设备有限公司

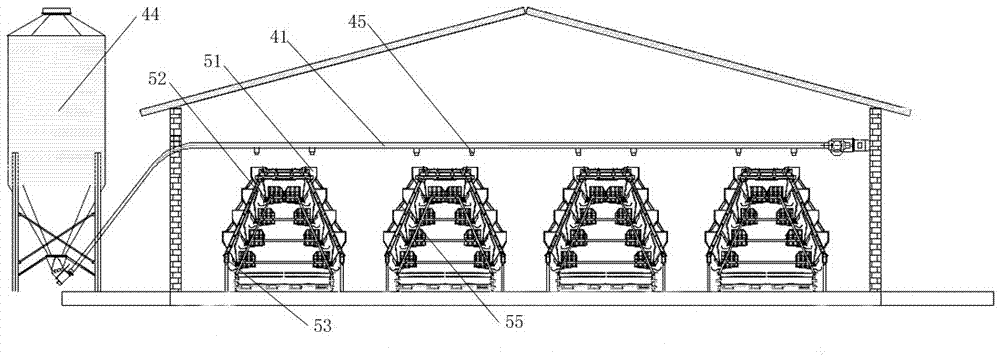

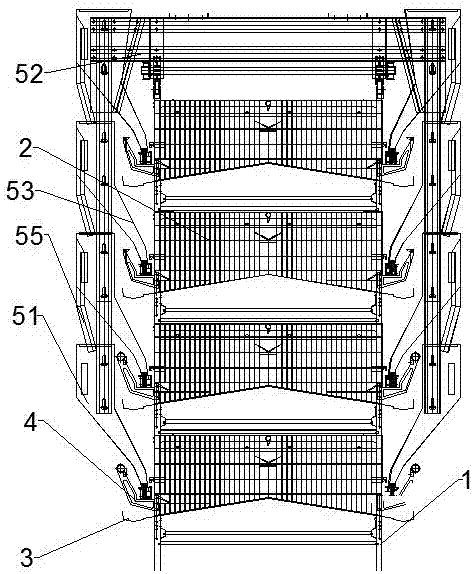

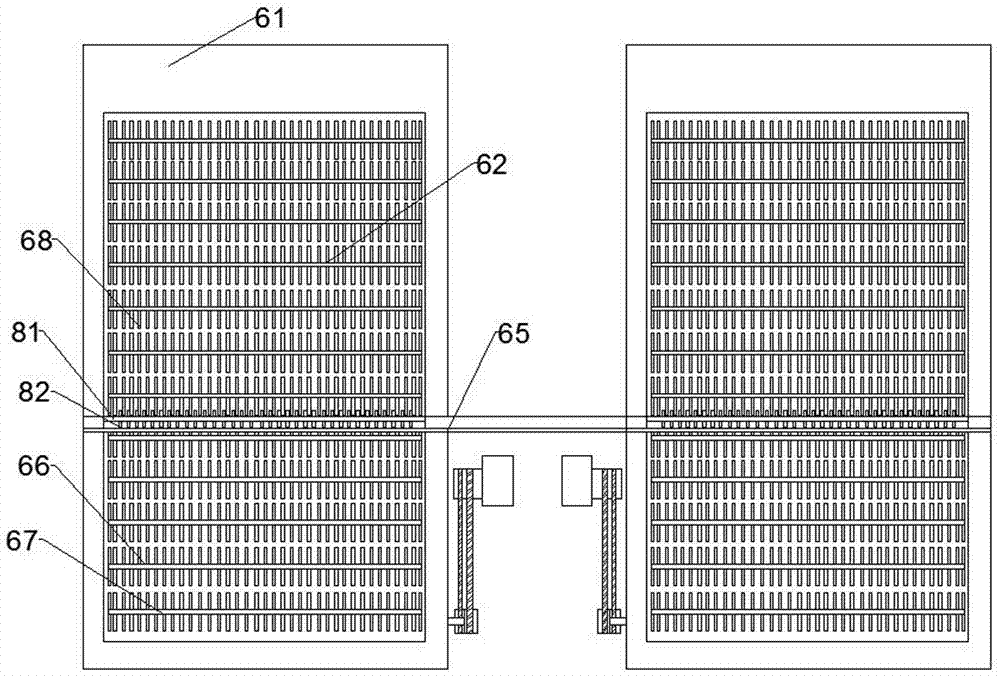

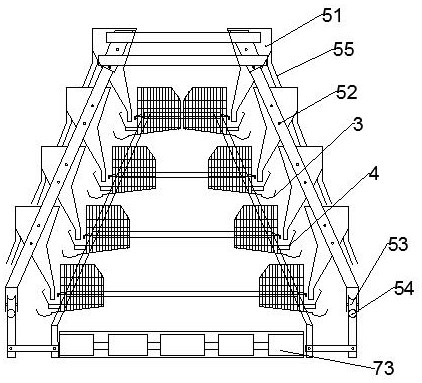

Laminated laying hen cage

The invention discloses a laminated laying hen cage comprising a laying hen cage body, a feeding device, an egg collector, a waterer, and a manure cleaner; the laying hen cage body comprises a cage frame and a cage arranged in the cage frame and having more than two layers; the cage body having more than two layers are laminated up and down; each cage layer is divided into two rows of symmetrical cage units; an egg holder is respectively arranged below each row of the cage unit; a hopper is arranged outside each row of the cage units; the feeding device is arranged above the hopper; the egg collector is arranged on the side face of the laying hen cage body and connected with the egg holders; the waterer is arranged in the cage body; the manure cleaner is arranged below each cage layer. The laminated laying hen cage is reasonable in structure, has stepped walls, so the laying hen cage is small in land occupation, and very suitable for large-scale hen farmers.

Owner:河南金牧人机械设备有限公司

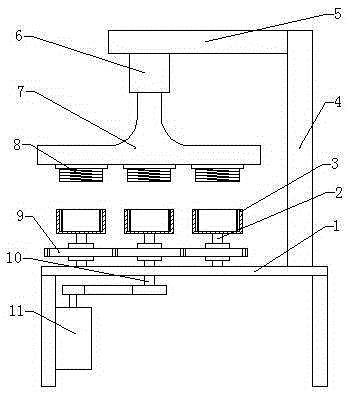

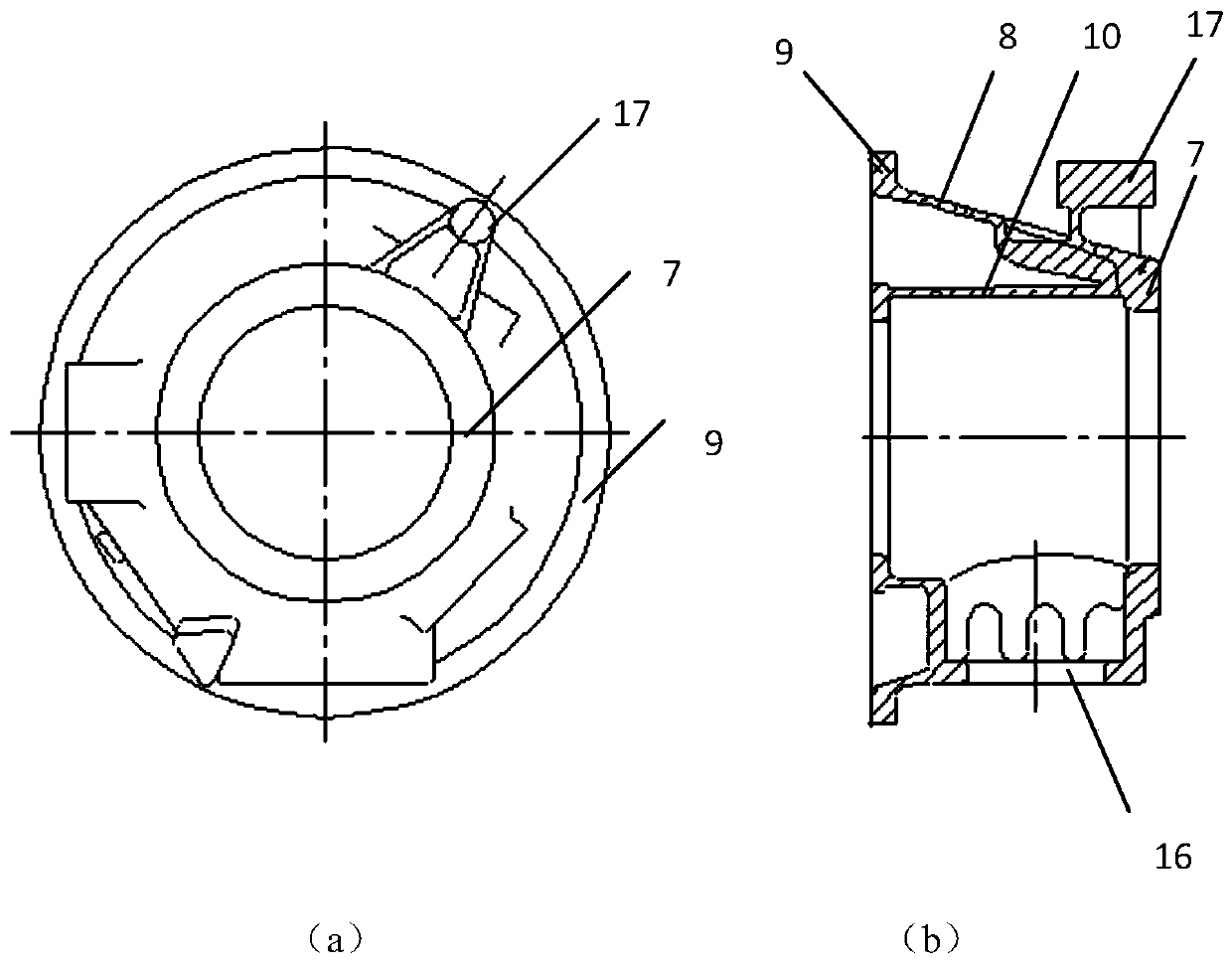

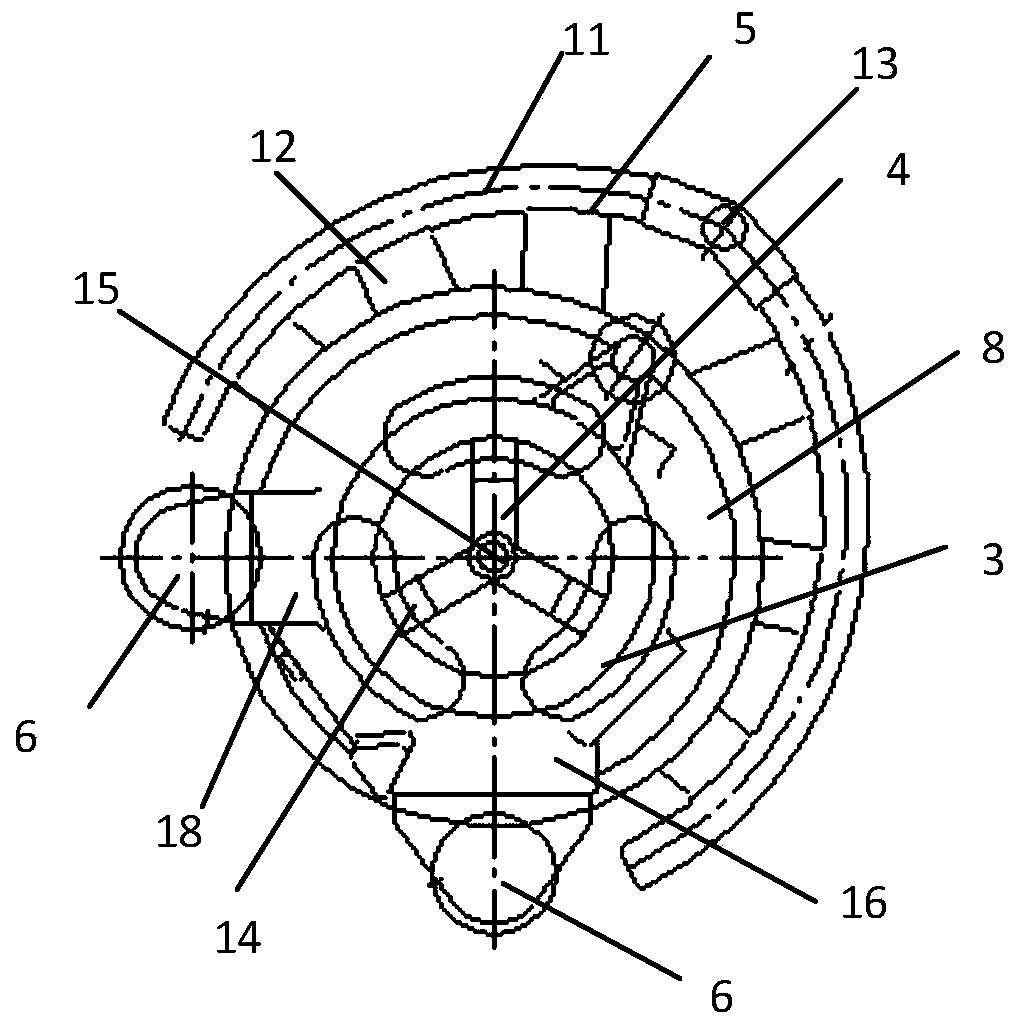

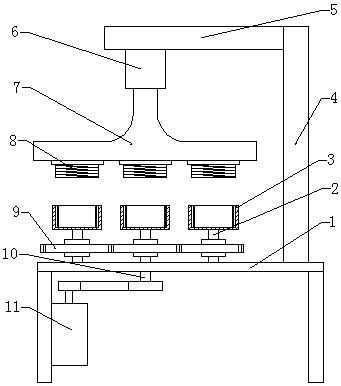

Copper sleeve centrifugal casting device

The invention discloses a copper sleeve centrifugal casting device in the copper sleeve production field; and the copper sleeve centrifugal casting device comprises a frame, a motor, a cylinder, casting molds and a mold cover. A support column is fixed on the frame; a cantilever is fixed at the top end of the support column; and the cylinder is fixed at a free end of the cantilever. The mold cover is fixed at an output end of the cylinder; and multiple resistance rings are arranged on the mold cover. A driving shaft is inserted in the middle part of the frame; multiple transmission shafts are uniformly and annularly distributed around the driving shaft; and gears are respectively arranged on the driving shaft and the transmission shafts. Multiple casting molds are provided, and are respectively fixed at the top ends of the driving shaft and the transmission shafts; and the resistance rings are corresponding to the casting molds one to one. The casting molds are double-layer structures provided with heating cavities. The motor is fixed below the frame; and the output end of the motor is connected with the driving shaft. A molded copper sleeve is excellent in feeding conditions, compact in structure and uniform in density, generates no deformation or cracks due to stress concentration in use, and is better in quality; and the centrifugal casting molding of multiple copper sleeves can be synchronously finished, so that the production efficiency of the copper sleeves is greatly improved.

Owner:CHONGQING YUANCHUANG AUTOMATION EQUIP

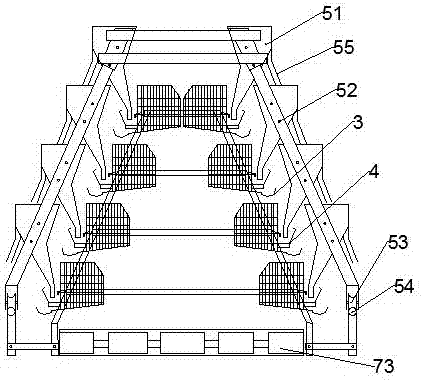

Cascade type chicken raising equipment

InactiveCN102771413AReduce concentrationClean up thoroughlyBird housingsEngineeringRespiratory disease

The invention discloses cascade type chicken raising equipment. The cascade type chicken raising equipment is characterized in that multi-layer chicken coops are arranged on the two sides of a ladder-shaped chicken coop frame, dung conveying belts are flatly arranged at the bottoms of the multi-layer chicken coops, and are connected with a driving device arranged at the bottom of one end of the ladder-shaped chicken coop frame. According to the cascade type chicken raising equipment, due to the arrangement, the concentration of harmful gas such as ammonia in the chicken coop is low, so that the environment of the chicken coop is improved greatly, the morbidity of respiratory disease of the chickens can be reduced, and the breeding condition is improved.

Owner:SHANDONG HENGIN AGRI & ANIMAL HUSBANDRY MACHINERY

Internal gear box casting structure and method

The invention discloses an internal gear box casting structure and method. The casting structure is characterized in that a bottom pouring type pouring system is adopted, and the lower part is provided with a bottom layer runner. In the improved pouring system, an upper layer supplementary runner is arranged on the upper part of the root part of a casting riser, so that the temperature gradient during solidification of a casting can be adjusted; the feeding effect of the riser is improved; and meanwhile the local overheating phenomenon is improved. Through the implementation of the casting structure, metallurgical defects such as cracks, loosening and slag inclusion in the casting production process are overcome; the yield of the casting is improved by 50 percent; the waste loss is reduced; and the cost is lowered.

Owner:AECC AVIATION POWER CO LTD

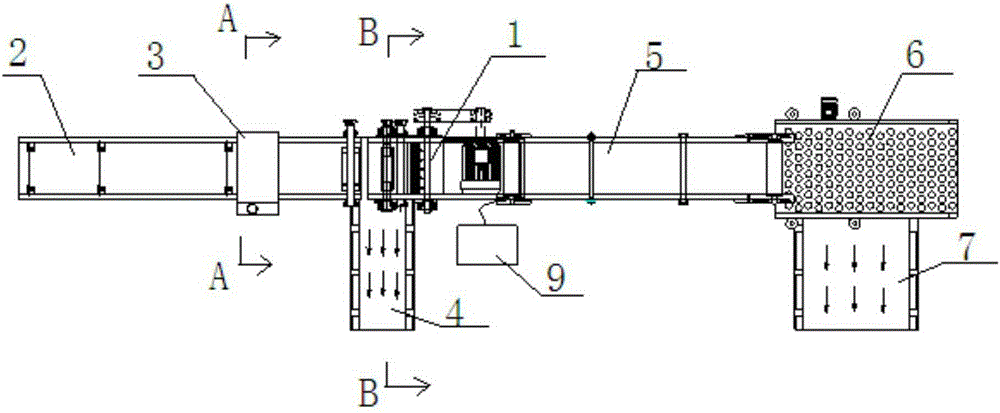

Magnetic separation method of high-purity iron powder

InactiveCN104056716AIncrease the depth of magnetic separationImprove feeding conditionsMagnetic separationHigh frequencyMagnetic separation

The invention relates to a magnetic separation method of high-purity iron powder, which comprises the following steps: (1) feeding crude powder with a particle size of 200 microns and a Fe content of 55% into a first magnetic separator through a high frequency sieve, wherein the field intensity of the first magnetic separator is 1600-12000 e, after magnetic separation, feeding the material into a second magnetic separator with a field intensity of 4000-30000 e; (2) after magnetic separation, feeding the material into a third magnetic separator with a field intensity of 5000-60000 e; (3) performing magnetic separation to obtain fine powder with a particle size of 60 microns and a detected Fe content of 66%. The method of the invention realizes recovery in different degrees of iron minerals with different magnetic properties in iron ore through stepwise magnetic separation, effectively improves the magnetic separation depth, improves the ore feeding conditions for subsequent working, reduces the grade of tailing ore metal elements, thus increases the recovery rate of iron element by 2-3%, realizes emission reduction and efficiency improvement, and improves economic benefits.

Owner:TIANJIN XINLING IRON POWDER SELECTING

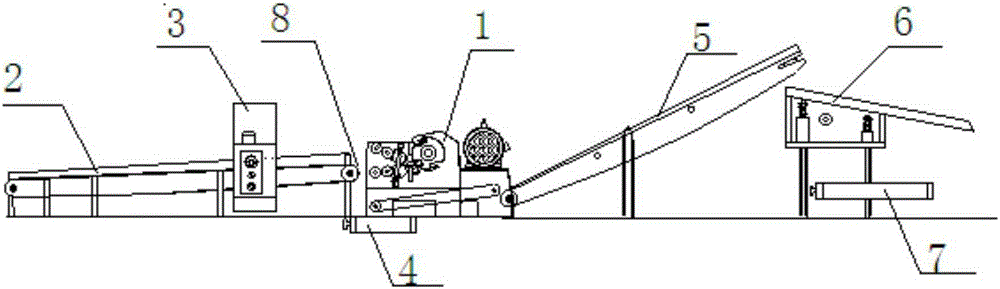

High-quality biomass fuel processing system

InactiveCN105217263AEfficient removalImprove qualityControl devices for conveyorsMechanical conveyorsIron removalControl system

The invention discloses a high-quality biomass fuel processing system which comprises a chipping machine. The feeding end of the chipping machine is connected with the output end of a feeding belt conveyor which is provided with an iron removal alarm. The discharging end of the chipping machine is connected with the input end of a discharging belt conveyor. The output end of the discharging belt conveyor is connected with a vibration screen. A first impurity removal belt conveyor is arranged below the vibration screen. The high-quality biomass fuel processing system is an impurity removal, crushing and processing system specifically designed for biomass, iron blocks, mud and other impurities mixed in the biomass can be effectively removed, and therefore the quality of biomass fuel is substantially improved. The iron removal alarm gives out an alarm and sends out a signal to a control system when detecting iron components, and an operator quickly and accurately finds out and takes out the iron impurities according to the alarm position. Thus, the processing efficiency of the biomass fuel is improved, and the equipment safety in the processing system and the personal safety of operation staff of the processing system are also effectively guaranteed.

Owner:格薪源生物质燃料有限公司

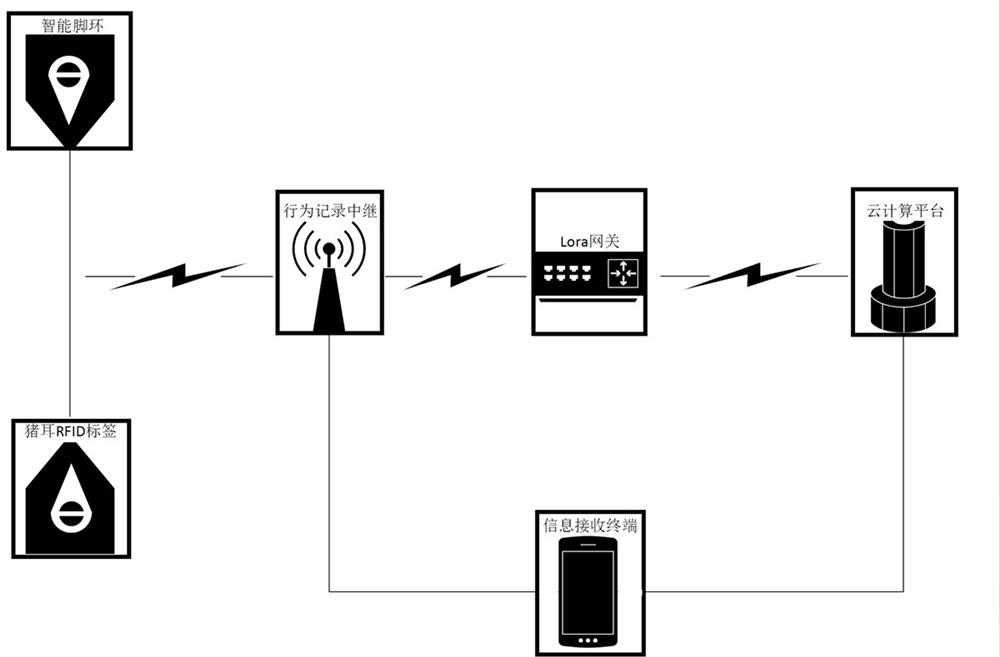

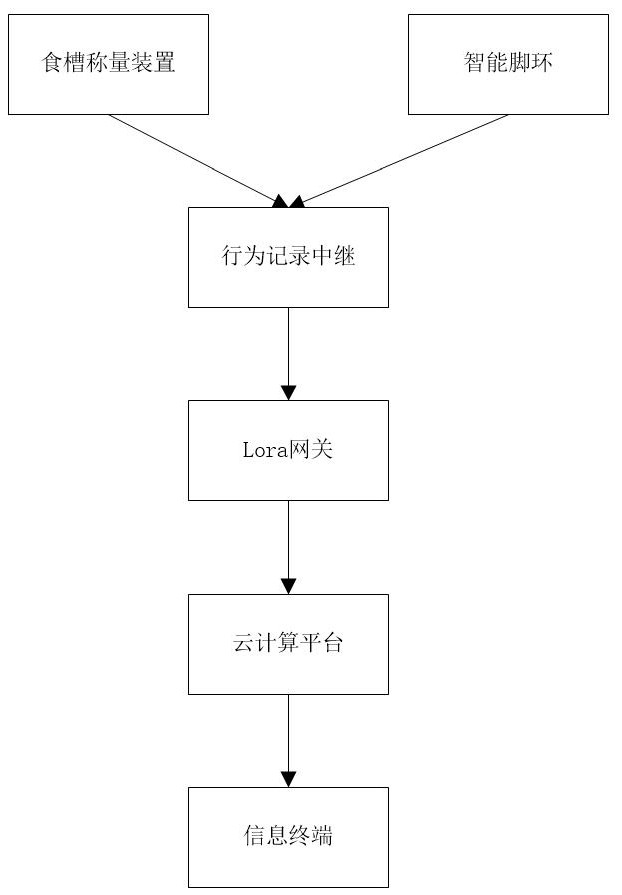

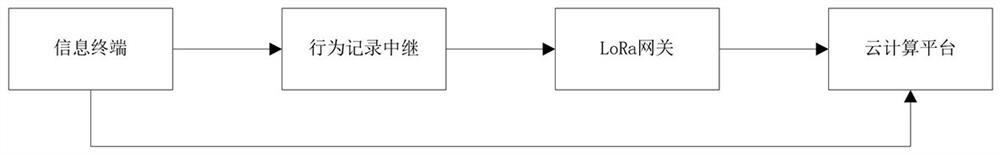

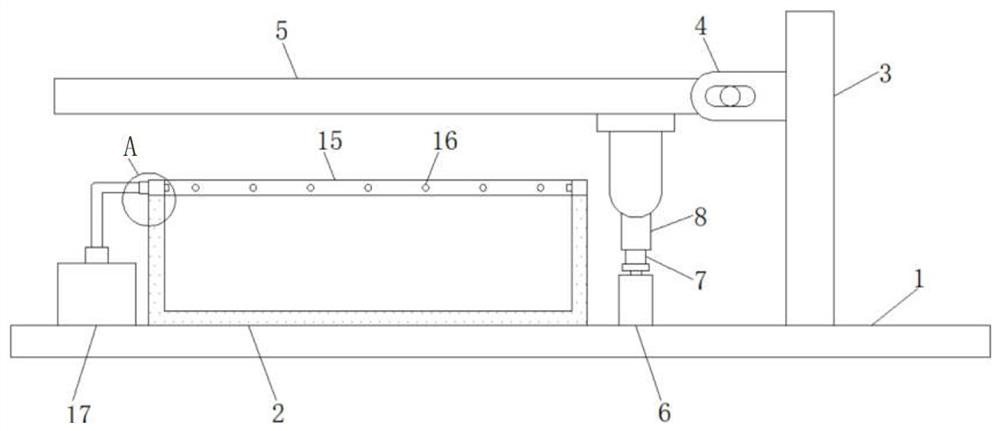

Sow health monitoring system

PendingCN113951168AAccurate grasp of reproductionAccurately grasp the health statusTransmission systemsResourcesUser PrivilegeMonitoring system

The invention provides a sow oestrus and health monitoring system. The sow oestrus and health monitoring system comprises an automatic feeding station, an RFID tag, an intelligent leg ring, a LoRa gateway, a cloud computing platform and an information terminal, is characterized in that the automatic feeding station and the intelligent leg ring collect sow activity data, upload the sow activity data to a behavior record relay, then upload the sow activity data to the LoRa gateway, and finally transmit the sow activity data to the cloud computing platform. A database of the cloud computing platform records data and manages user permission. The information terminal may obtain data from the cloud computing platform and may alter data located in the database or the behavior record relay according to user rights. By adopting the monitoring method, a better feeding condition can be provided for each sow, the number of non-production days of the sow is reduced, the production efficiency of sow breeding is improved, the experience accumulation demand of workers is reduced, and the human resource cost is saved.

Owner:CHONGQING ACAD OF ANIMAL SCI

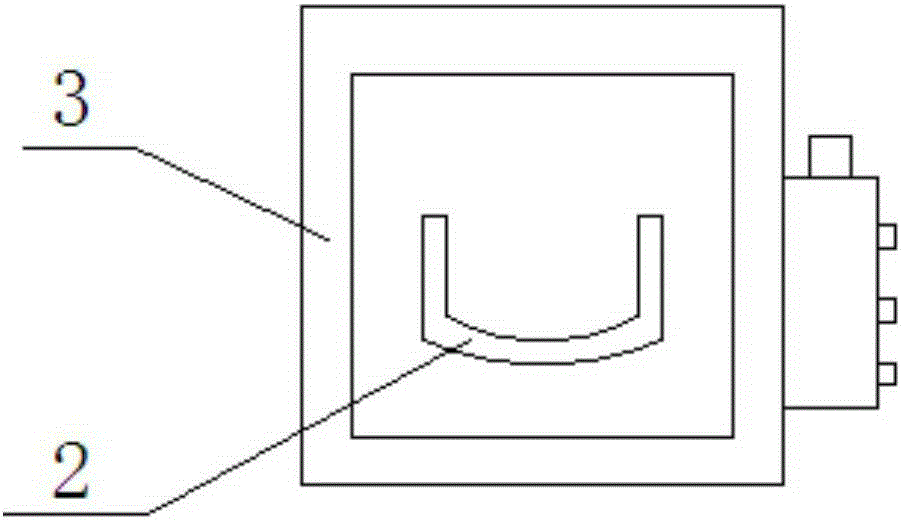

Giant salamander open-air breeding device

PendingCN112314530AIncrease air flowImprove feeding conditionsPisciculture and aquariaGiant salamanderEnvironmental geology

The invention provides a giant salamander open-air breeding device. The giant salamander open-air breeding device comprises a base, a breeding pond is fixedly arranged on the base, a first air pipe iserected on the breeding pond, a plurality of second air pipes are arranged on the first air pipe at equal intervals, a fixing plate is fixedly installed on the base, a sun shield is movably installedon the fixing plate, and an angle adjusting device is installed between the sun shield and the base. According to the giant salamander open-air breeding device, the first air pipe is installed on thebreeding pond, oxygen is supplied into the first air pipe through an air pump and then dispersed into multiple second air pipes through the first air pipe to be slowly blown to the breeding pond, airflow above the breeding pond is improved, and then the breeding condition is improved; the sun shield is driven by the motor to conduct angle adjustment, so that the breeding pond can be shaded conveniently, and giant salamanders in the breeding pond can be conveniently cared and observed in the later period.

Owner:竹溪县隆源大鲵生物开发有限公司

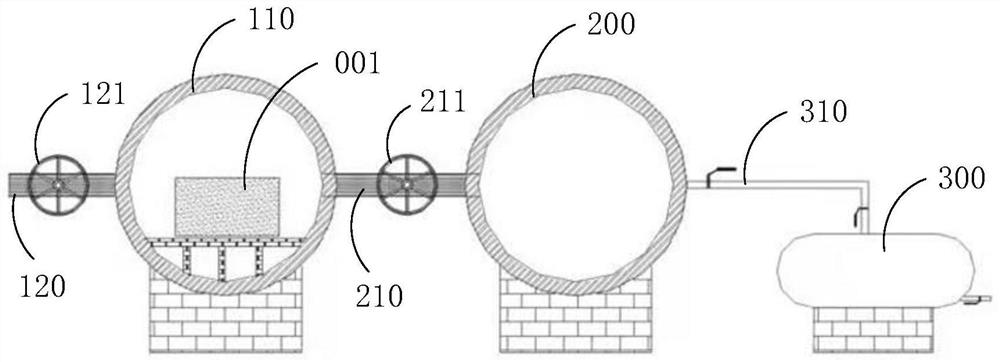

Casting process and casting system

PendingCN114346178ARefined organizationImprove feeding conditionsFoundry mouldsFoundry coresShrinkage porosityMaterials science

The invention provides a casting process and a casting system, and relates to the technical field of casting, the casting process provided by the invention comprises the following steps: assembling: assembling sand cores into a sand bag; mold filling is conducted, specifically, the assembled sand bag is moved to a pouring device to be subjected to mold filling; and solidification is conducted, specifically, the sand bag after mold filling is moved into a high-pressure environment to be solidified. According to the casting process provided by the invention, the technical problems of shrinkage cavities, shrinkage porosity, coarse grains, incompactness, poorer mechanical property and the like of castings in related technologies are relieved.

Owner:SUZHOU MINGZHI TECH

Ecological aquaculture pond

PendingCN112493018AMake the most ofMeet the needs of sunshineClimate change adaptationPisciculture and aquariaZoologyBiological organism

The invention discloses an ecological aquaculture pond. The pond comprises an aquaculture pond body, a pond object inlet is formed at the upper side of the aquaculture pond body, a feeding mechanism is arranged at the outer end of the aquaculture pond body, and an ecological planting groove is formed at the position, at the outer end of the aquaculture pond body, of the lower side of the feeding mechanism; a sludge collecting chamber is arranged at the bottom of the aquaculture pond body, a sludge discharging opening is formed at one side of the sludge collecting chamber, a groove is formed atthe lower side of the outer side of the aquaculture pond body, the groove is sunken towards the interior of the aquaculture pond body to form an inner convex seat, and an aquaculture pond main body is arranged in the aquaculture pond body; and a creature feeding rest platform is arranged at the position, located at the upper end in the aquaculture pond body, of the inner convex seat, and a waterlevel height control mechanism is arranged at one side of the inner convex seat. According to the ecological aquaculture pond, the function of amphibious coexistence of aquatic plants, crabs, turtles,snakes and the like is achieved, water level control of the pond can be guaranteed, and the functionality is greatly improved.

Owner:东莞其力行科技有限公司

Casting structure and casting method of internal gear box

The invention discloses a casting structure and casting method of an internal gear box. The casting structure adopts a bottom pouring type pouring system, and a bottom runner is arranged at the lower part. The improved pouring system is provided with an upper supplementary runner at the upper part of the riser root of the casting. It can adjust the temperature gradient when the casting is solidified, increase the feeding effect of the riser, and improve the local overheating phenomenon at the same time. Through the implementation of the casting structure, metallurgical defects such as cracks, looseness, and slag inclusions in the casting production process are reduced, the qualified rate of the casting is increased by 50%, the loss of waste products is reduced, and the cost is saved.

Owner:AECC AVIATION POWER CO LTD

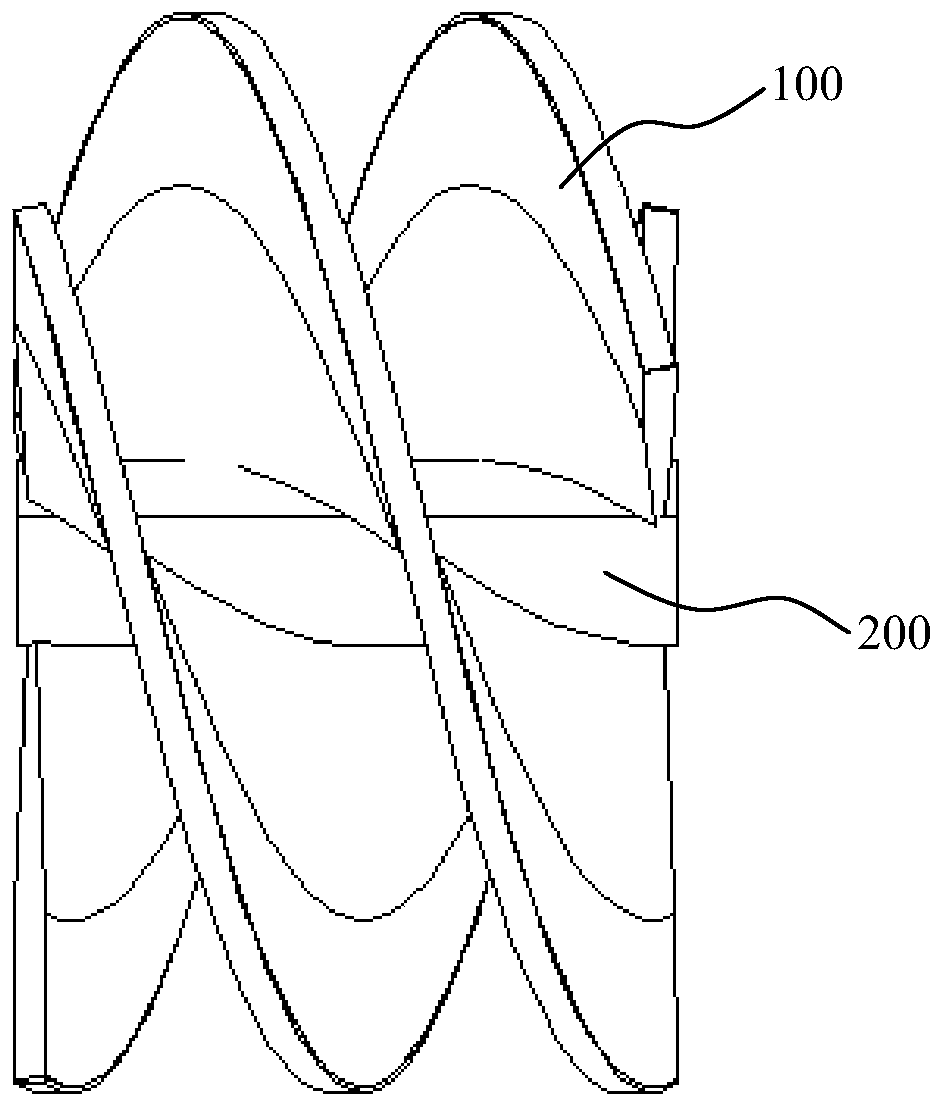

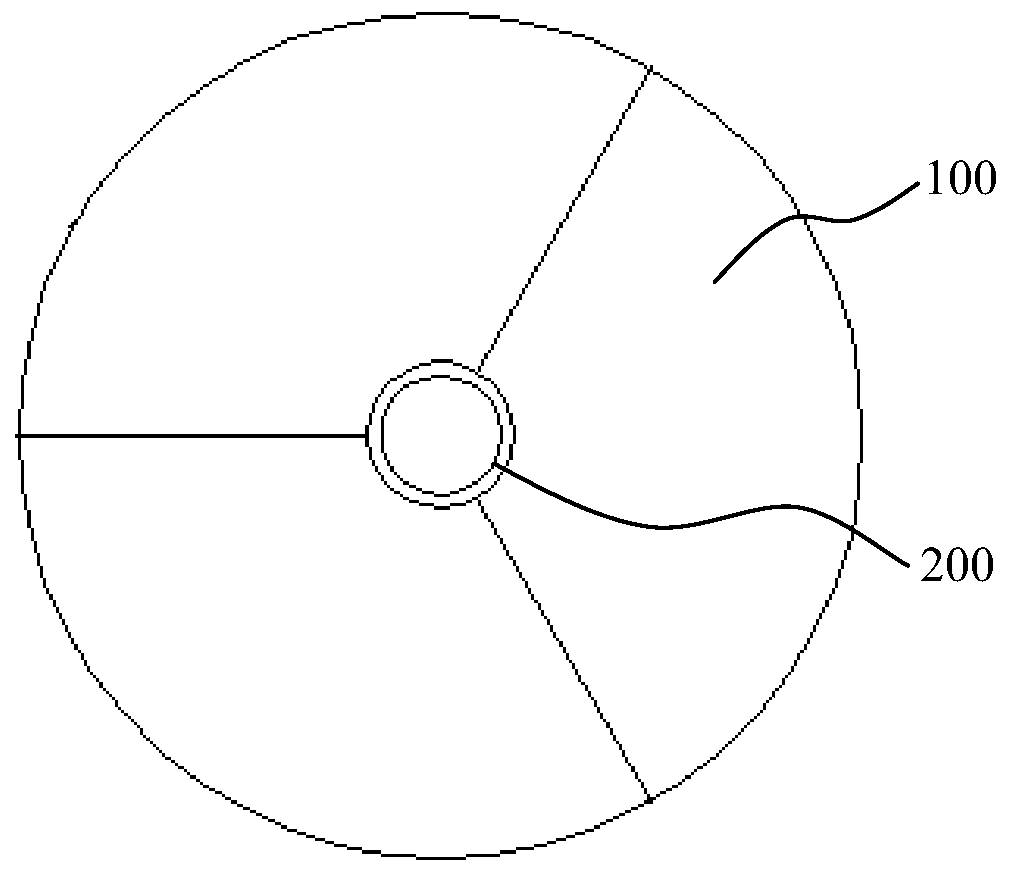

A kind of centrifugal casting stirring impeller and method

The invention discloses a centrifugally-cast stirring impeller and a method, and belongs to the technical field of impeller production. A plate of the impeller is prepared from chemical components bymass: 2.3-3.0% of C, smaller than or equal to 1.0% of Si, 0.5-1.0% of Mn, 17-23% of Cr, 0.3-0.8% of Mo, smaller than or equal to 0.035% of P, smaller than or equal to 0.06% of S, 0-1.5% of Ni, 0-1.0%of Co, 0-2.0% of Cu and the balance Fe and inevitable impurities. A hub is prepared from chemical components by mass: 0.3-0.4% of C, 0.6-0.9% of Si, 0.9-1.2% of Mn, 1.8-2.2% of Cr, 0.3-0.8% of Mo, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, 1.6-2.0% of Ni, 0.3-0.8% of Co and the balance Fe and inevitable impurities.

Owner:马鞍山市庄芝耐磨合金有限公司

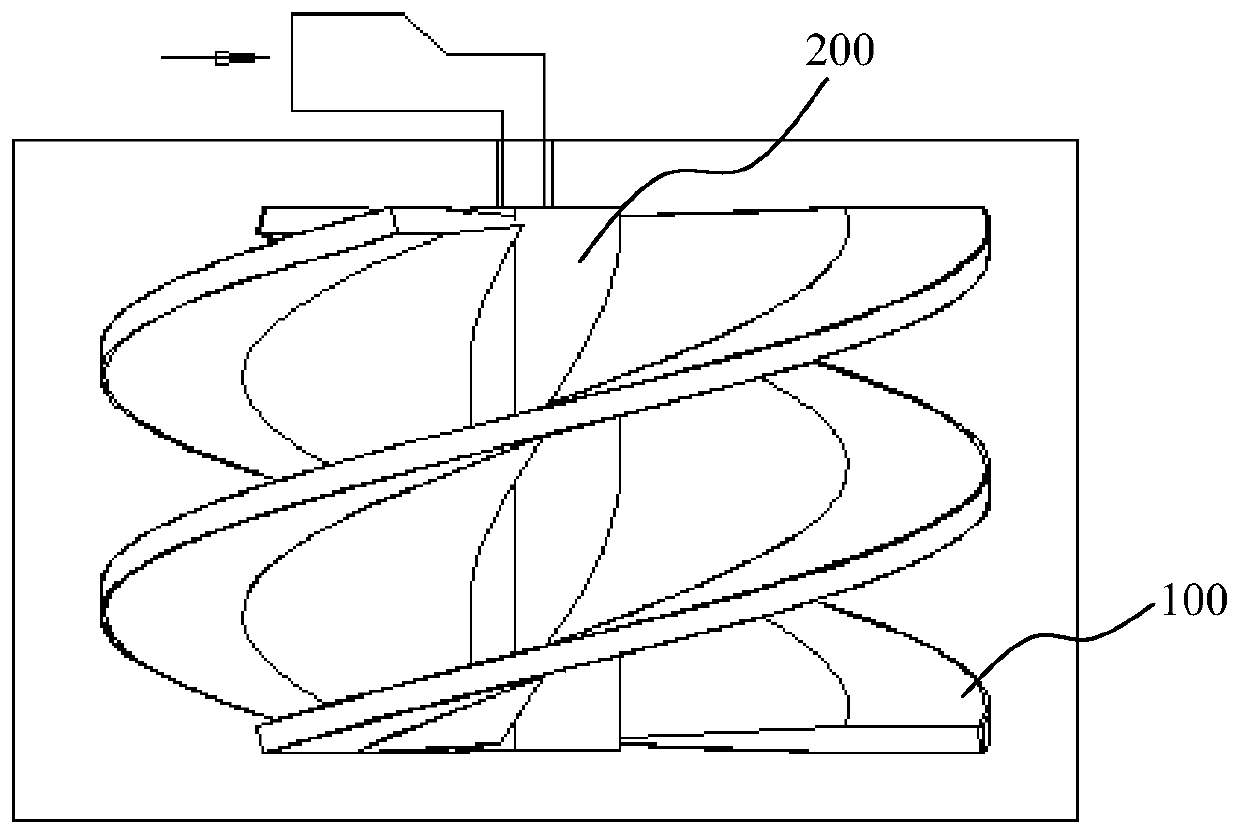

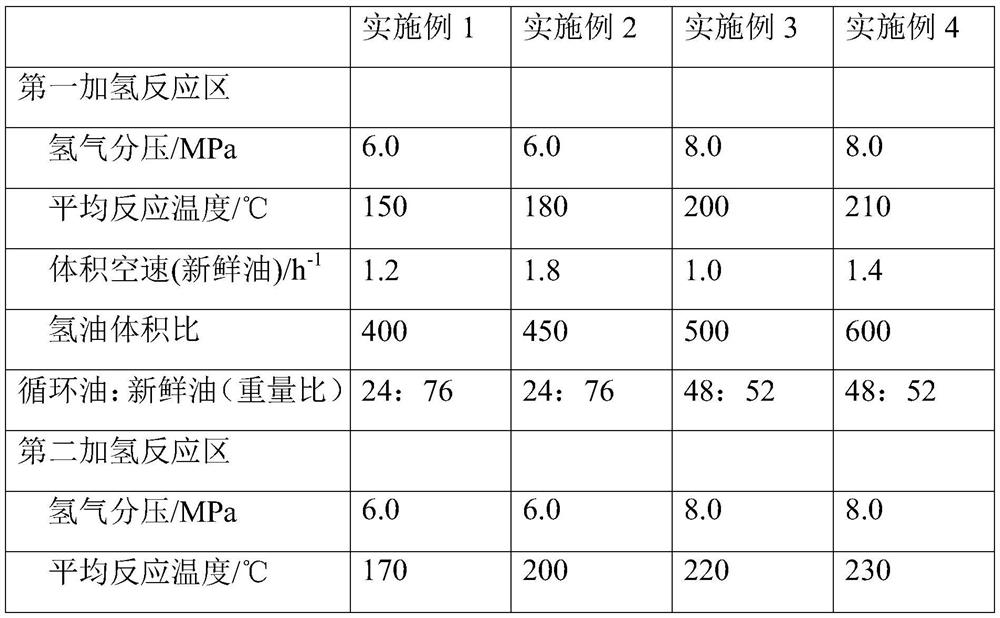

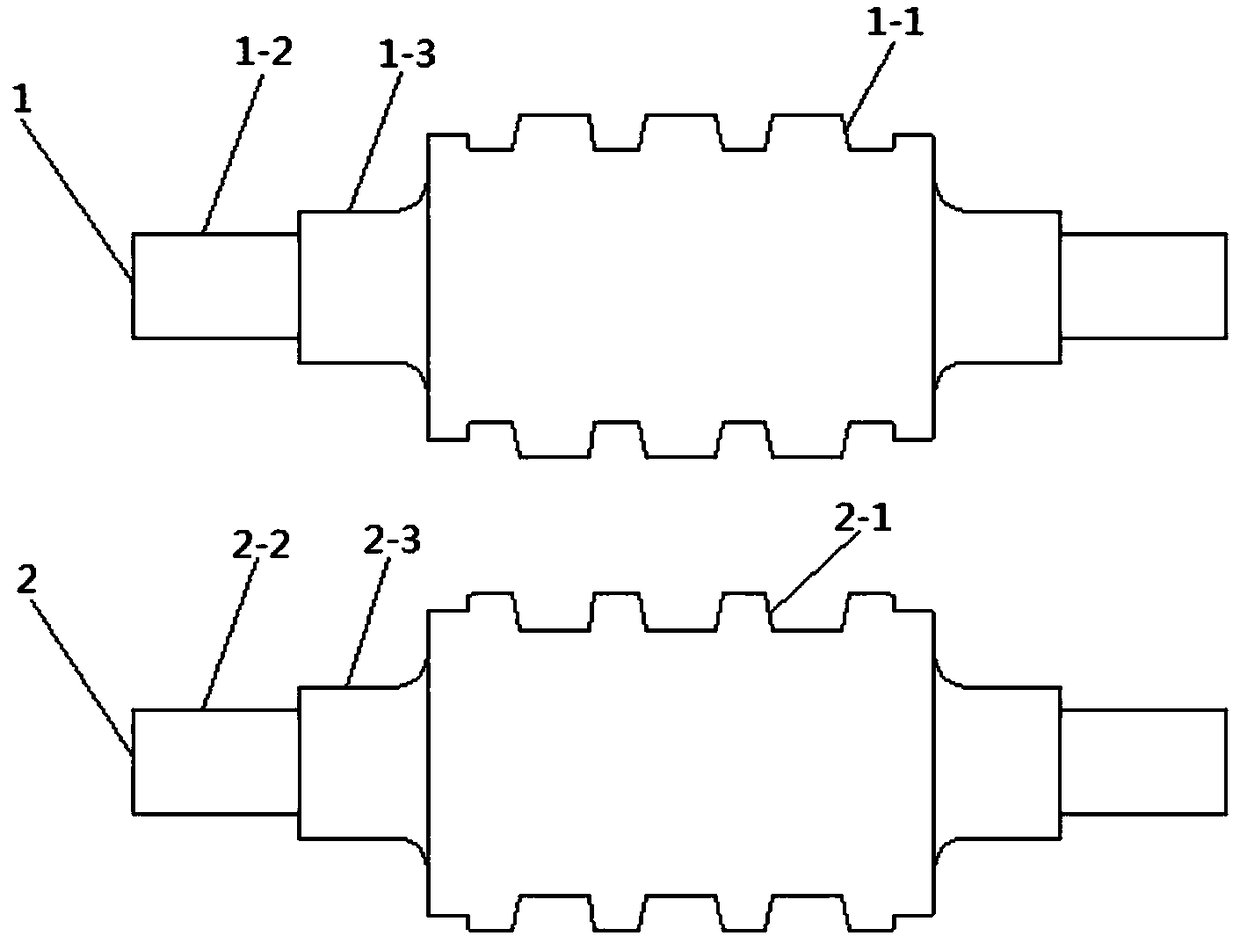

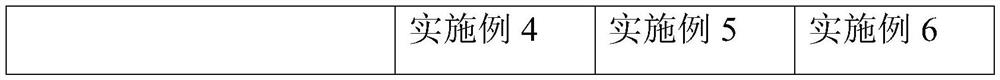

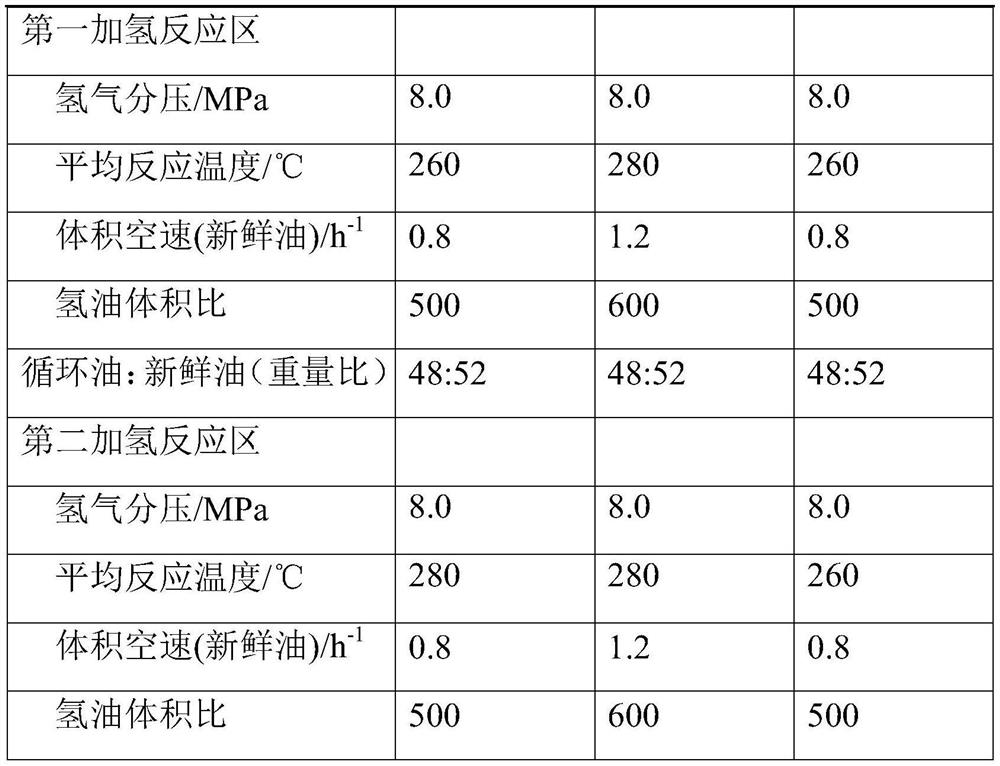

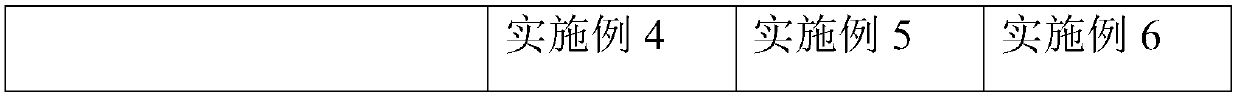

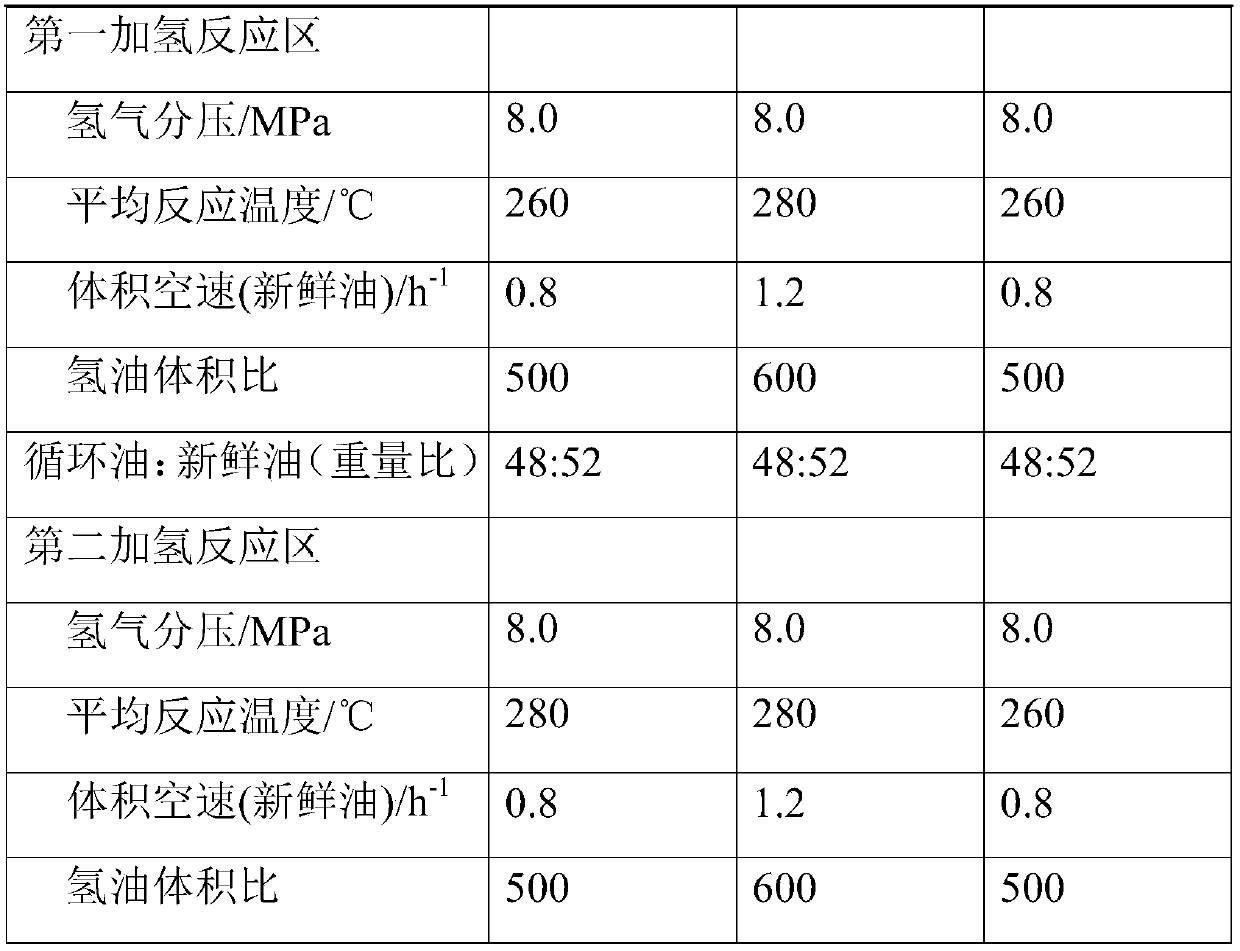

A method for hydrogenation of high-viscosity polyalphaolefin synthetic oil

ActiveCN111073703BHigh aspect ratioGood dispersionTreatment with hydrotreatment processesPolyolefinFluid phase

A method for hydrogenation of high-viscosity polyalphaolefin synthetic oil. The raw material of high-viscosity polyalphaolefin synthetic oil is mixed with circulating oil and then enters the first hydrogenation reaction zone and the second hydrogenation reaction zone for reaction. The reaction effluent is passed through After gas-liquid separation, the obtained liquid stream is subjected to fractionation to obtain light materials and heavy materials. The light materials are recycled to the raw material tank as circulating oil, and the heavy materials are refined polyalphaolefin synthetic oil products. The treatment method provided by the present invention improves the feeding status of the fixed-bed hydrogenation reactor, and solves the problem of partial flow of materials in the fixed-bed bed layer or incomplete hydrogenation in the fixed-bed hydrogenation reactor existing in the prior art , and obtained high-quality refined polyalphaolefin synthetic oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

ladder layer cage

The invention discloses a stepped laying hen cage, which comprises a laying hen cage main body, a feeding device, an egg collecting device, water drinking devices and a manure cleaning device, wherein the laying hen cage main body comprises a hen cage frame and more than four hen cage bodies; the hen cage frame is a trapezoidal frame; the hen cage bodies are symmetrically arranged at two sides of the hen cage frame to form a stepped structure; an egg tray is arranged at the lower part of each hen cage body; a trough is arranged in the outer side of each hen cage body; the feeding device is arranged above the troughs; the egg collecting device is arranged on the side surface of the laying hen cage main body and connected with the egg trays; the water drinking device is arranged in each hen cage body; and the manure cleaning device is arranged at the lower part of the laying hen cage main body. The stepped laying hen cage is high in automatic degree, full-automatic control on loading, feeding, water drinking, manure cleaning, egg collecting and environment is achieved, the labor intensity is greatly reduced and the labor cost is saved.

Owner:河南金牧人机械设备有限公司

Copper sleeve centrifugal casting device

The invention discloses a copper sleeve centrifugal casting device in the copper sleeve production field; and the copper sleeve centrifugal casting device comprises a frame, a motor, a cylinder, casting molds and a mold cover. A support column is fixed on the frame; a cantilever is fixed at the top end of the support column; and the cylinder is fixed at a free end of the cantilever. The mold cover is fixed at an output end of the cylinder; and multiple resistance rings are arranged on the mold cover. A driving shaft is inserted in the middle part of the frame; multiple transmission shafts are uniformly and annularly distributed around the driving shaft; and gears are respectively arranged on the driving shaft and the transmission shafts. Multiple casting molds are provided, and are respectively fixed at the top ends of the driving shaft and the transmission shafts; and the resistance rings are corresponding to the casting molds one to one. The casting molds are double-layer structures provided with heating cavities. The motor is fixed below the frame; and the output end of the motor is connected with the driving shaft. A molded copper sleeve is excellent in feeding conditions, compact in structure and uniform in density, generates no deformation or cracks due to stress concentration in use, and is better in quality; and the centrifugal casting molding of multiple copper sleeves can be synchronously finished, so that the production efficiency of the copper sleeves is greatly improved.

Owner:CHONGQING YUANCHUANG AUTOMATION EQUIP

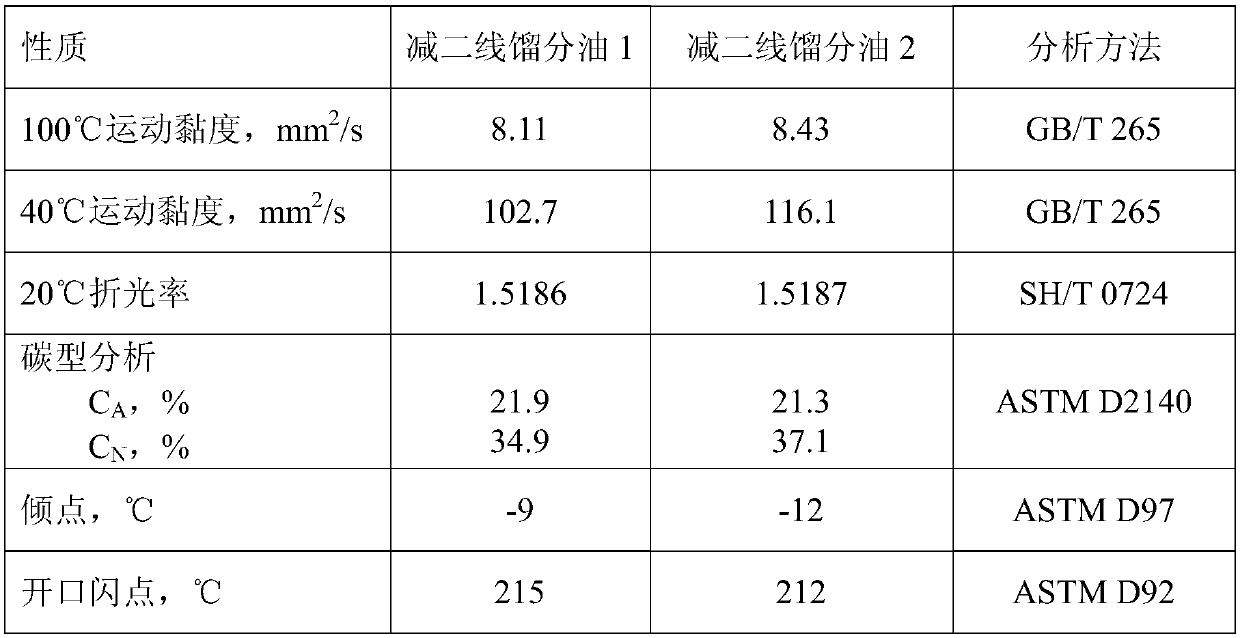

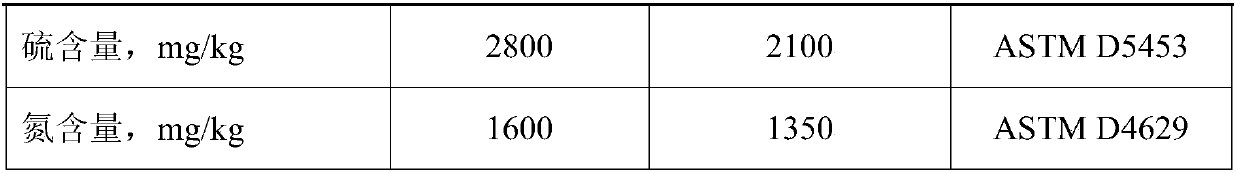

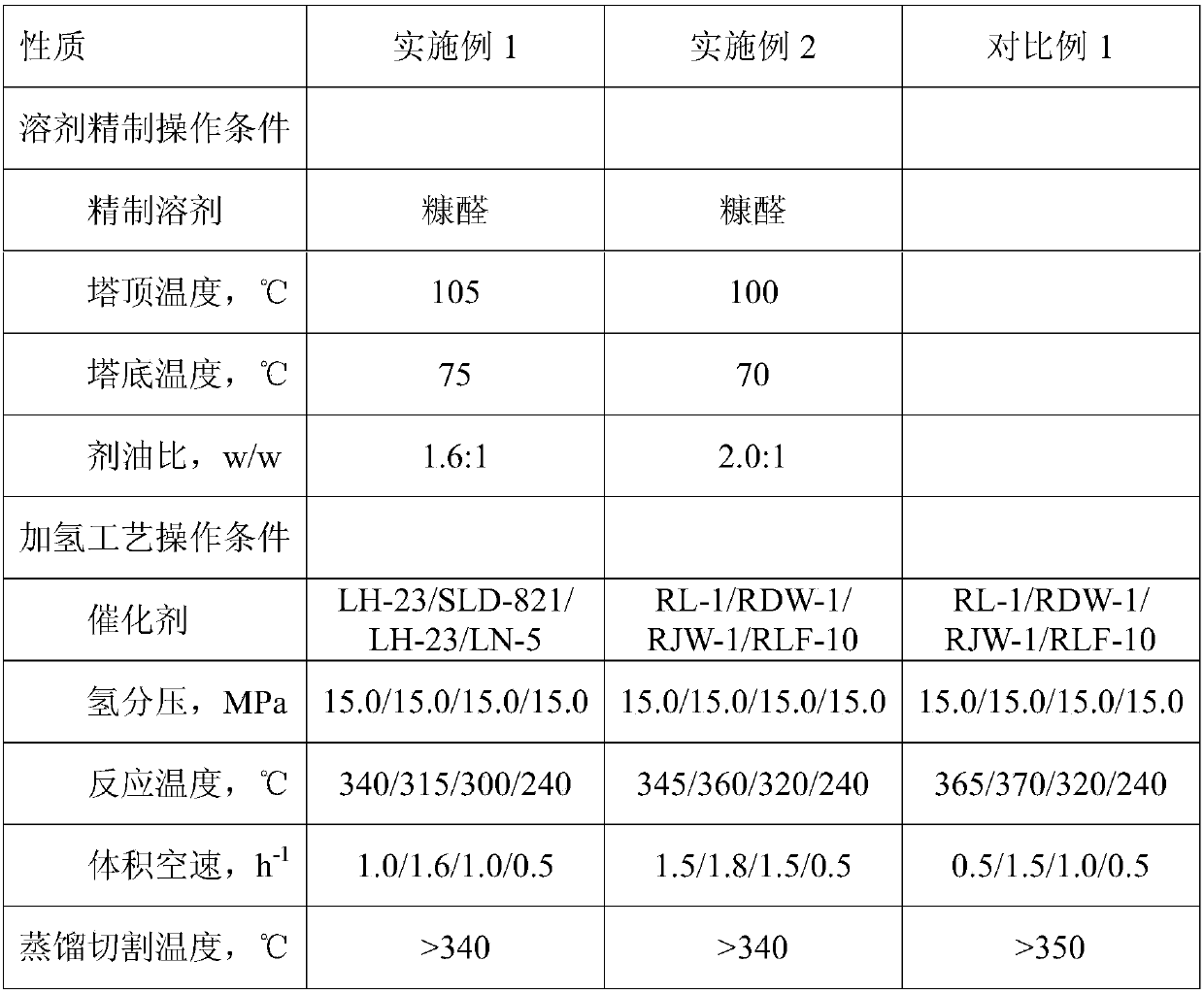

A kind of special white oil for polystyrene and preparation method thereof

ActiveCN106479565BIncreased cycloalkane contentGood light and heat stabilityTreatment with hydrotreatment processesCycloparaffinsDistillation

The invention discloses special white oil for polystyrene and a preparation method of the special white oil. The preparation method of the special white oil for the polystyrene comprises the following steps: 1) carrying out solvent refining on fraction oil of naphthenic base crude oil in an extraction tower; obtaining an extracted solution at the tower bottom of the extraction tower, and obtaining a refined solution at the tower top of the extraction tower; recycling a solvent to obtain refined oil; 2) carrying out a hydrogenation process and distillation and cutting on the refined oil to obtain the special white oil for the polystyrene, wherein the hydrogenation process comprises the steps of hydrogenation treatment, catalytic dewaxing, hydrogenation refining and hydrogenation to deeply saturate aromatic hydrocarbon in sequence. By adopting the preparation method disclosed by the invention, a feeding condition of a hydrogenation device can be effectively improved and operation conditions of the hydrogenation device are alleviated; the content of cycloparaffin in the PS white oil is effectively increased; harmful substances including the aromatic hydrocarbon and the like in an oil product can be deeply removed through a plurality of sections of hydrogenation processes, and application performance and safety of the PS white oil are guaranteed. The special white oil for the polystyrene, disclosed by the invention, exceeds an existing product level; meanwhile, the preparation method is stable and reliable and has moderate operation conditions.

Owner:CHINA NAT OFFSHORE OIL CORP +3

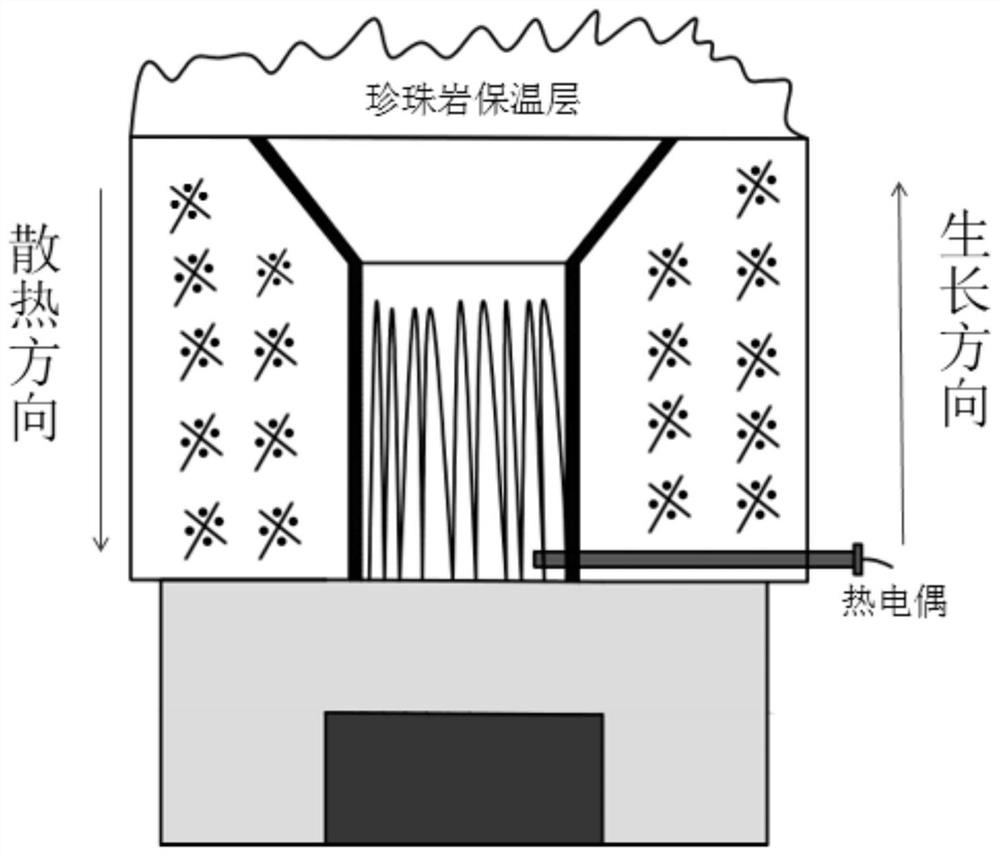

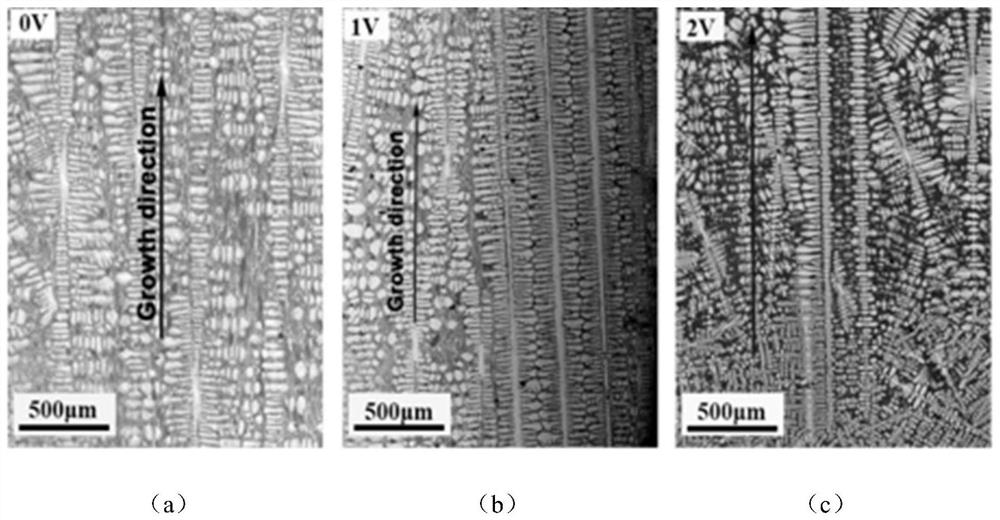

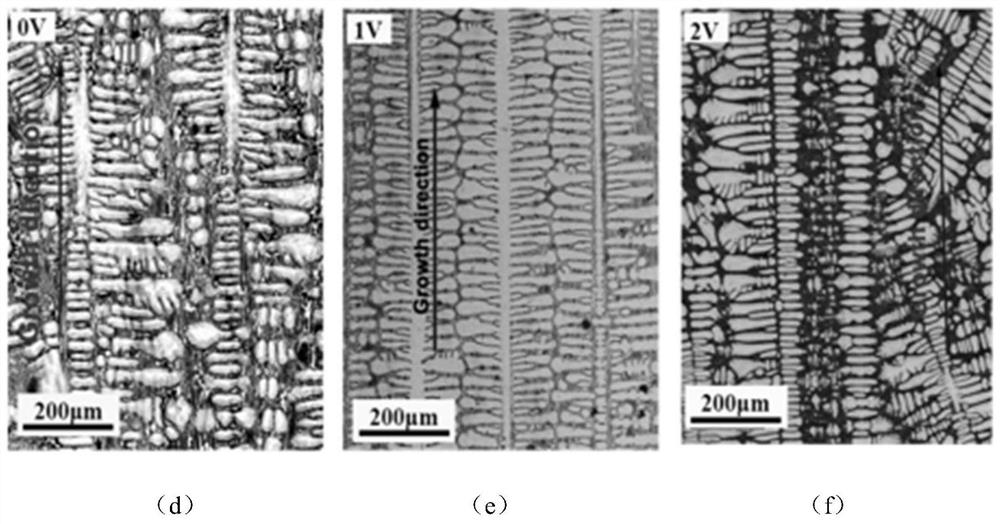

Directional solidification high-boron high-vanadium high-speed steel and production method thereof

ActiveCN113718160AGood filling abilityExcellent feeding conditionsCasting safety devicesFerrosiliconDirectional solidification

The invention discloses directional solidification high-boron high-vanadium high-speed steel and a production method thereof. The production method of the directional solidification high-boron high-vanadium high-speed steel comprises the following steps: with pig iron, waste steel, low-carbon ferrochrome, ferromanganese, ferroboron, ferrovanadium, industrial pure iron, ferromolybdenum, ferrotungsten, ferrosilicon and / or ferrotitanium as raw materials, conducting smelting treatment at the temperature of 1580-1600 DEG C, and then conducting refining treatment to obtain molten high-boron high-vanadium high-speed steel; and subjecting the molten high-boron high-vanadium high-speed steel to overheating heat preservation treatment, then controlling the pouring temperature to be 1420-1430 DEG C for directional solidification treatment, and waiting for the temperature to drop to the room temperature to obtain the directional solidification high-boron high-vanadium high-speed steel. The high-boron high-vanadium high-speed steel is produced by adopting a directional solidification technology, and the grain orientation of a solidification structure can be well controlled through the directional solidification technology, so that the high-boron high-speed steel presents certain orientation, a continuous columnar crystal structure is formed, thus various kinds of performance of the material is greatly improved, and compared with common high-boron high-speed steel, the high-boron high-speed steel has better performance.

Owner:XI AN JIAOTONG UNIV

Casting technique of heavy duty trucks gear box and die

The invention relates to a forging process for a heavy truck gearbox and a die, which are used for forging the heavy truck gearbox. The forging process is characterized by adopting low-pressure forging; the forging die consists of an upper die and a lower die, wherein the upper die comprises an upper module, an upper die carrier, core pulling mechanisms, a composite positioning sleeve and a casting ejecting and resetting mechanism; the upper die carrier is connected with a machine tool; the number of the core pulling mechanisms is three; the lower die comprises a lower module, a lower die carrier and a composite positioning pin; a pouring head I (12) and a pouring head II (13) are arranged in the lower module; and the lower die carrier is connected with the machine tool. The forging process and the die do not need expensive investment, and can produce casting products according with requirements; the casting has no riser head, the pouring heads are small, and the utilization rate of the molten metal is high; the arrangement of the double pouring heads effectively shortens the filling stroke of the molten metal, and improves the feeding conditions when the casting is solidified; the casting is solidified under definite pressure to increase the consistency of casting tissues and improve the quality of the casting; and the production efficiency is high, and few auxiliary materials are consumed.

Owner:NINGBO HELI TECH CO LTD

A sorting process for processing magnetic red mixed ore based on iron mineral embedding particle size

ActiveCN109351467BEfficient sorting processReduce energy consumptionSolid separationMagnetiteMagnetic separation

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

A high-speed steel section steel finished roll and its preparation method

The invention relates to a high-speed steel and section steel finished roller and a preparation method thereof. According to the high-speed steel and section steel finished roller and the preparation method thereof, first configuration, second configuration and third configuration are adopted for chemical components of the outer layer, chemical components of the middle layer and chemical components of the center part of the roller respectively; and then smelted molten steel meeting requirements is poured into a high-speed steel and section steel roller mold in a centrifugal and composite mode, and then the thickness, the hardness, the tensile strength and the matrix structure of the working layer of the roller can be obtained through special heat treatment. Compared with common section steel rollers, the high-speed steel and section steel finished roller has the advantages that the wear resistance (the uniformity), the impact toughness, the thermal fatigue resistance and the tensile strength are improved, the service life of the high-speed steel and section steel roller is prolonged, and the surface quality of the high-speed steel and section steel roller is improved.

Owner:江苏凯达重工股份有限公司

A hydrogenation method for producing polyalphaolefin synthetic oil products

ActiveCN111073700BHigh aspect ratioGood dispersionTreatment with hydrotreatment processesPolyolefinFluid phase

A hydrogenation method for producing polyalphaolefin synthetic oil products. The high-viscosity polyalphaolefin synthetic oil raw material and circulating oil are mixed and then sequentially enter the first hydrogenation reaction zone and the second hydrogenation reaction zone for reaction, and the reaction effluent is passed through After gas-liquid separation, the obtained liquid stream is subjected to fractionation to obtain light materials and heavy materials. The light materials are recycled to the raw material tank as circulating oil, and the heavy materials are refined polyalphaolefin synthetic oil products. The treatment method provided by the present invention improves the feeding status of the fixed-bed hydrogenation reactor, and solves the problem of partial flow of materials in the fixed-bed bed layer or incomplete hydrogenation in the fixed-bed hydrogenation reactor existing in the prior art , and obtained high-quality refined polyalphaolefin synthetic oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing poly-alpha olefin synthetic oil product

ActiveCN111073700AHigh aspect ratioGood dispersionTreatment with hydrotreatment processesPolyolefinFluid phase

The invention discloses a hydrogenation method for producing a poly-alpha olefin synthetic oil product. The method comprises the following steps that a high-viscosity poly-alpha olefin synthetic oil raw material and circulating oil are mixed, and sequentially enter a first hydrogenation reaction zone and a second hydrogenation reaction zone and are subjected to reactions; and the reaction effluentis subjected to gas-liquid separation, and the obtained liquid phase material flow is fractionated to obtain a light material and a heavy material, wherein the light material as circulating oil is circulated to a raw material tank, and the obtained heavy material is the refined poly-alpha olefin synthetic oil product. By adopting the treatment method provided by the invention, the feeding condition of the fixed bed hydrogenation reactor is improved, the problem of bias flow or incomplete hydrogenation of the material in a fixed bed layer in a fixed bed hydrogenation reactor in the prior art is solved, and a refined poly-alpha olefin synthetic oil product with excellent quality is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

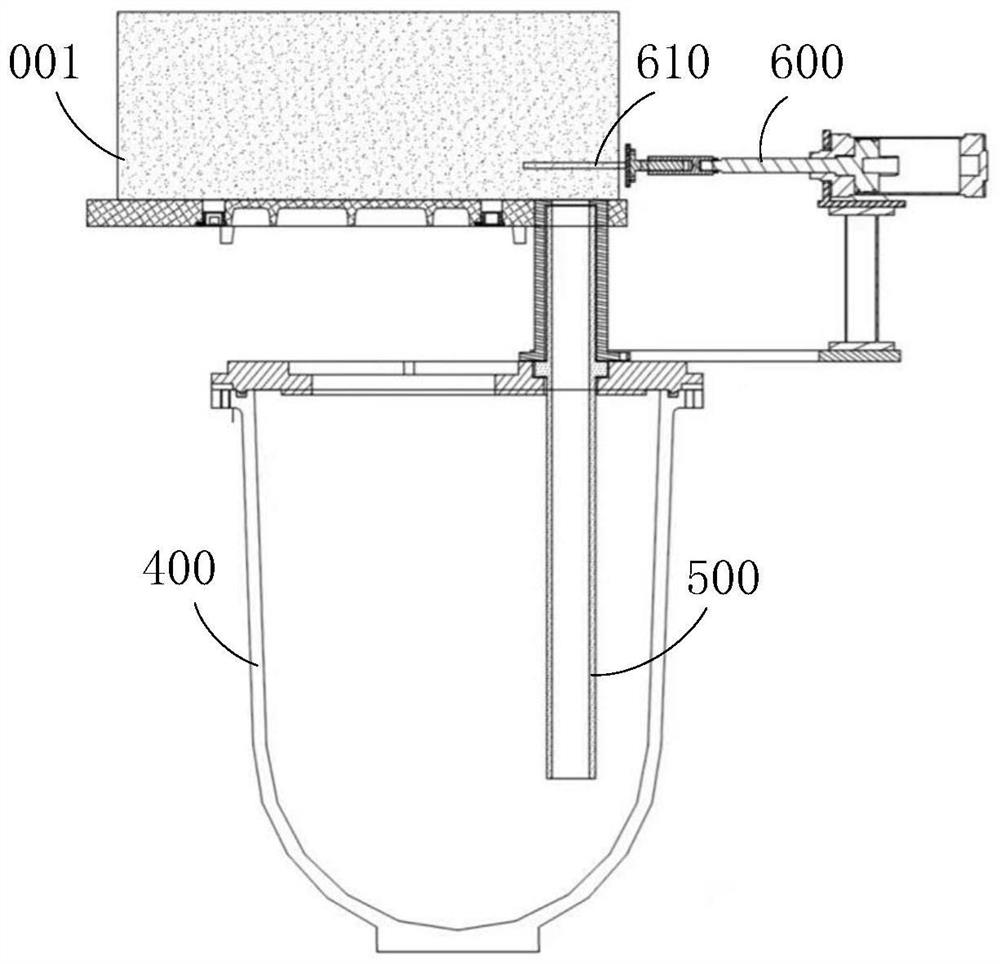

A kind of tooling and casting method of casting nicralysi alloy target material

ActiveCN104399897BSimple structureImprove use reliabilityVacuum evaporation coatingFoundry mouldsGraphiteAlloy

The invention discloses a tool for casting a NiCrAlYSi alloy target. The tool comprises a steel bucket of which the upper end is opened, wherein a graphite pad plate is arranged above the bottom of the steel bucket; a graphite mold is arranged above the graphite pad plate; an insulated feeder in a matching manner with the graphite mold is arranged at the upper end of the graphite mold; a cooling water tube is wound on the outer wall of the graphite mold in a spiral manner; one end of the cooling water tube penetrates outside the steel bucket and is used as a water inlet; the other end of the cooling water tube penetrates outside the steel bucket and is used as a water outlet; the water inlet is positioned below the water outlet; the space inside the steel bucket and on the outer side of the graphite mold is filled with aluminum oxide sand; the height of the top end of the aluminum oxide sand is no greater than that of the upper end of the graphite mold. In addition, the invention further discloses a method for casting the NiCrAlYSi alloy target by using the tool. The tool disclosed by the invention has the characteristics of simple structure, high use reliability, low cost, high repeated operability and the like.

Owner:西安诺博尔稀贵金属材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com