A high-speed steel section steel finished roll and its preparation method

A technology for finished steel and high-speed steel, which is applied in the field of finished high-speed steel section steel rolls and their preparation, can solve the problems of micro-concave indentation, pass failure section steel surface quality, large extrusion load, etc., achieves fewer defects and saves metal consumption , the effect of reducing the grain growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

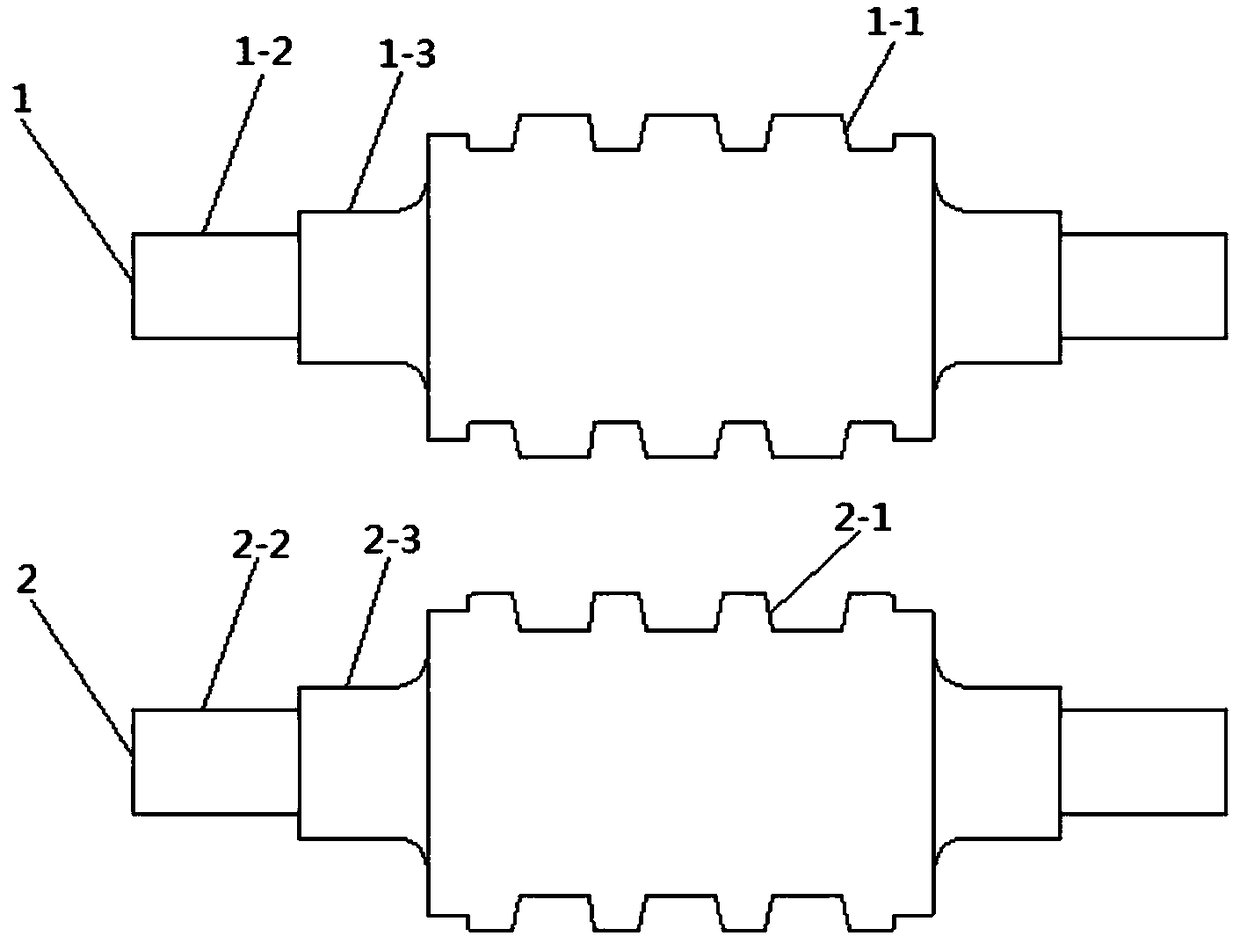

[0027] [Example 1] The structure of the high-speed steel section steel finished roll of the present embodiment is as follows figure 1 Shown: the assembly of a kind of high-speed steel shaped steel finished roll of the present embodiment: comprise two working layer matrix organizations are: Cr 23 C 6 、Mo 2 C 6 , NbC, V 4 C 3 Fine eutectic granular carbide + bainite + martensite high-speed steel section steel finished rolls, one of which is used as the main shaft 1, and the other is used as the auxiliary shaft 2, and the two mesh with each other; the main shaft includes the roll body 1 located in the middle -1 and the roll neck 1-2 located at both ends of the roll body 1-1, the bearing stop roll neck 1-3; the auxiliary shaft includes the roll body 2-1 located in the middle and the roll neck 2-2 located at the two ends of the roll body 2-1 , Bearing stop roll neck 2-3.

[0028] The main shaft 1 roll body 1-1 of the assembly of the roll includes 5 protrusions around the roll...

Embodiment 2

[0040] [Example 2] The chemical composition of each layer of the high-speed steel section steel roll is: Configuration 1C: 1.50; Si: 1.40; Mn: 0.35%; Cr: 1.95%; Ni: 3.10%; Mo: 4.30%; V: 2.85% ; W: 1.10%; Nb: 0.20%; P: 0.02%; S: 0.02%; configuration 2C: 3.30%; Si: 1.70%; 3.10%; Si: 2.25%; Mn: 0.33%; Cr: 0.12%; Ni: 0.021%; Mg: 0.06%; the rest is Fe and unavoidable trace impurities.

[0041] The design value of the hardness of the working layer of the high-speed steel section steel roll is 70-80HSD, and the actual product is 77.5HSD; the design value of the hardness drop from the roll surface to the bottom of the groove is ≤1.5HSD, and the actual product is 1.1HSD; The design value of the tensile strength of the working layer of the steel-shaped steel roll is ≥480MPa, and the measured value of the physical product is 510MPa; the design value of the tensile strength of the core part is ≥450MPa, and the measured value of the physical product is 480MPa.

[0042] The third step is t...

Embodiment 3

[0043] [Example 3] The chemical composition of each layer of the high-speed steel section steel roll is: configuration 1C: 1.60%; Si: 1.60%; Mn: 0.50%; Cr: 1.90%; Ni: 3.00%; Mo: 4.30%; V: 2.90%; W: 0.85%; Nb: 0.20%; P: 0.01%; S: 0.015%; Configuration 2C: 3.40%; Si: 1.70%; 3C: 3.40%; Si: 2.20%; Mn: 0.35%; Cr: 0.15%; Ni: 0.025%; Mg: 0.06%; the rest is Fe and unavoidable trace impurities.

[0044] The design value of the hardness of the working layer of the high-speed steel section steel roll is 70-80HSD, and the actual product is 77.3HSD; the design value of the hardness drop from the roll surface to the bottom of the groove is ≤1.5HSD, and the actual product is 1.32HSD; The design value of the tensile strength of the working layer of the steel-shaped steel roll is ≥480MPa, and the measured value of the physical product is 525MPa; the design value of the tensile strength of the core part is ≥450MPa, and the measured value of the physical product is 468MPa.

[0045] The third st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com