A method for hydrogenation of high-viscosity polyalphaolefin synthetic oil

A technology of α-olefin and synthetic oil, which is applied in the field of processing poly-α-olefin synthetic oil, can solve the problems of partial flow hydrogenation, incompleteness, etc., and achieve the effects of reducing axial back-mixing, improving aspect ratio, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

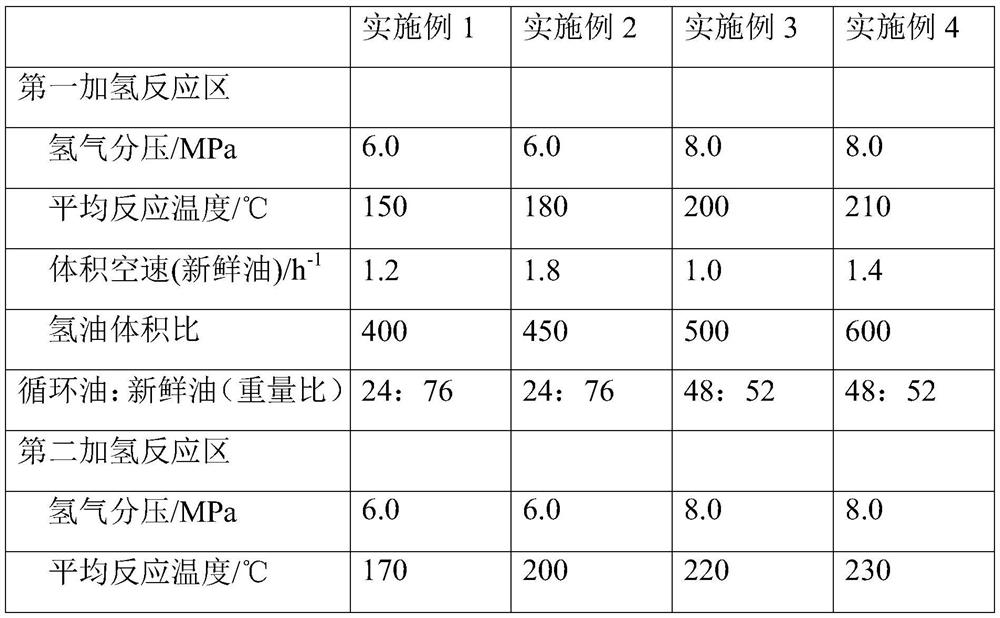

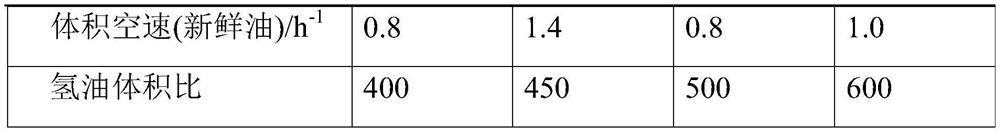

Embodiment 1

[0033] After the circulating oil and PAO60 raw material oil are mixed according to the weight ratio of 24:76, the 100°C kinematic viscosity of the mixed material is 28mm 2 / s, the heated mixed material enters the first hydrogenation reaction zone, and reacts with the hydrogenation protection agent and the hydrofinishing catalyst A successively in the presence of hydrogen, and the loading weight ratio of the hydrogenation protection agent and the hydrofinishing catalyst A The ratio is 2:8, the reaction effluent directly enters the second hydrogenation reaction zone to contact with the hydrofinishing catalyst A for reaction, and the reaction effluent is subjected to gas-liquid separation, and the obtained liquid phase stream is subjected to fractional distillation to obtain light materials and Heavy material, the light material is circulated to the raw material tank as circulating oil, and the heavy material is a refined polyalphaolefin synthetic oil product. The reaction condit...

Embodiment 2

[0035] After the circulating oil and PAO60 raw material oil are mixed according to the weight ratio of 24:76, the 100°C kinematic viscosity of the mixed material is 28mm 2 / s, the heated mixed material enters the first hydrogenation reaction zone, and reacts with the hydrogenation protection agent and the hydrofinishing catalyst A successively in the presence of hydrogen, and the loading weight ratio of the hydrogenation protection agent and the hydrofinishing catalyst A The ratio is 3:7, the reaction effluent directly enters the second hydrogenation reaction zone to contact with the hydrogenation catalyst B for reaction, and the reaction effluent is subjected to gas-liquid separation, and the obtained liquid phase stream is subjected to fractional distillation to obtain light materials and Heavy material, the light material is circulated to the raw material tank as circulating oil, and the heavy material is a refined polyalphaolefin synthetic oil product. The reaction conditio...

Embodiment 3

[0037] After the circulating oil and PAO60 raw material oil are mixed according to the weight ratio of 48:52, the kinematic viscosity of the mixed material at 100°C is 12mm 2 / s, the heated mixed material enters the first hydrogenation reaction zone, and reacts with the hydrogenation protection agent and the hydrofinishing catalyst A successively in the presence of hydrogen, and the loading weight ratio of the hydrogenation protection agent and the hydrofinishing catalyst A The ratio is 2:8, the reaction effluent directly enters the second hydrogenation reaction zone to contact with the hydrofinishing catalyst A for reaction, and the reaction effluent is subjected to gas-liquid separation, and the obtained liquid phase stream is subjected to fractional distillation to obtain light materials and Heavy material, the light material is circulated to the raw material tank as circulating oil, and the heavy material is a refined polyalphaolefin synthetic oil product. The reaction con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com