High-quality biomass fuel processing system

A biomass fuel and processing system technology, applied in the direction of conveyor objects, conveyor control devices, conveyors, etc., can solve the problem of affecting the personal safety of chipper operators, chipper parts smashing operators, and biomass fuel Problems such as large soil content, to achieve the effect of improving the removal rate of impurities, avoiding the blind area of lateral induction, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

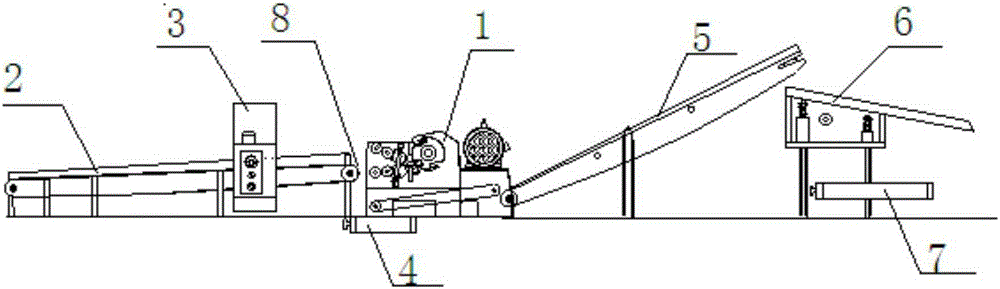

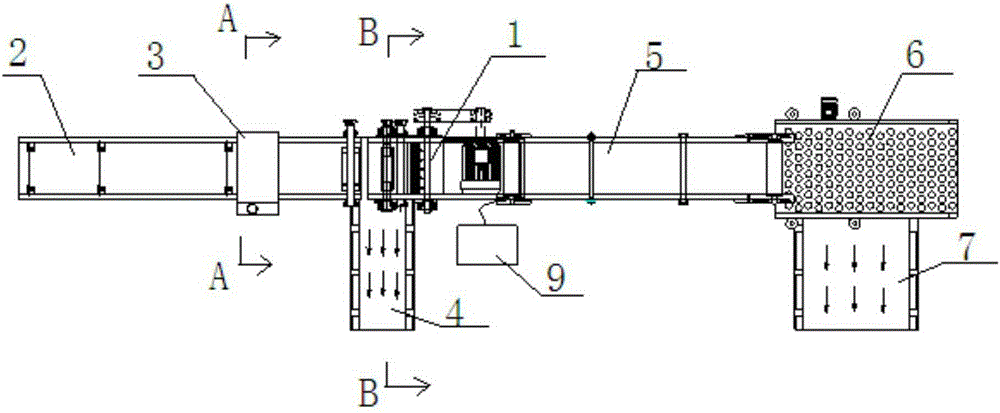

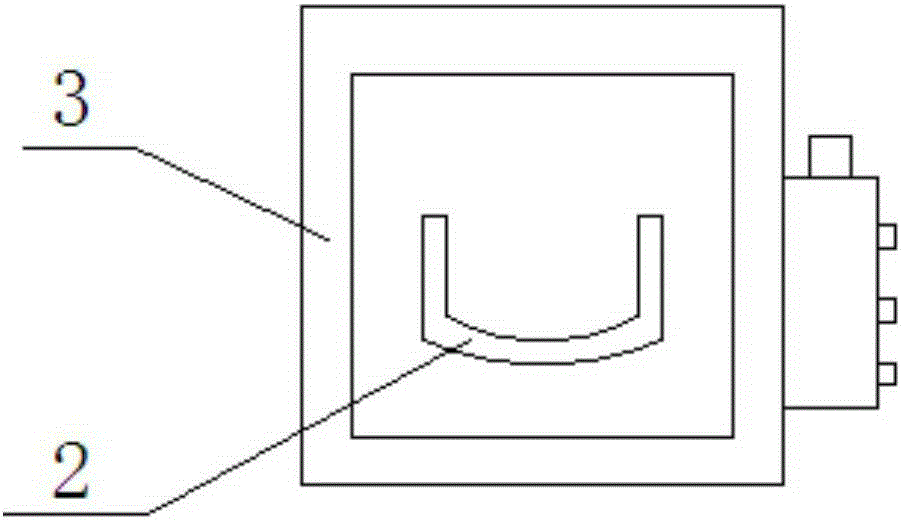

[0025] figure 1 , figure 2 A kind of high-quality biomass fuel processing system shown, comprises chipper 1, and the frame of chipper 1 is connected with the frame of feeding belt conveyor 2, and the output end of feeding belt conveyor 2 is connected with chipper The edge of the first feeding roller of machine 1 retains a 10-50mm wide leakage gap 8, and a second cleaning belt conveyor 4 is arranged below the leakage gap 8, and the material delivery direction of the second cleaning belt conveyor 4 Vertical to the feeding direction of the feeding belt conveyor 2 (such as Figure 4 As shown), the middle and rear part of the feeding belt conveyor 2 frame is equipped with an iron removal alarm 3, the discharge end of the chipper 1 is connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com