Directional solidification high-boron high-vanadium high-speed steel and production method thereof

A technology of directional solidification and high-speed steel, which is applied in the manufacture of tools, casting equipment, metal processing equipment, etc., can solve the problems of high brittleness of eutectic boron carbide, high brittleness of high-boron high-speed steel, and easy peeling of hot rolls, etc., to achieve Uniform distribution, reducing internal stress, and improving filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

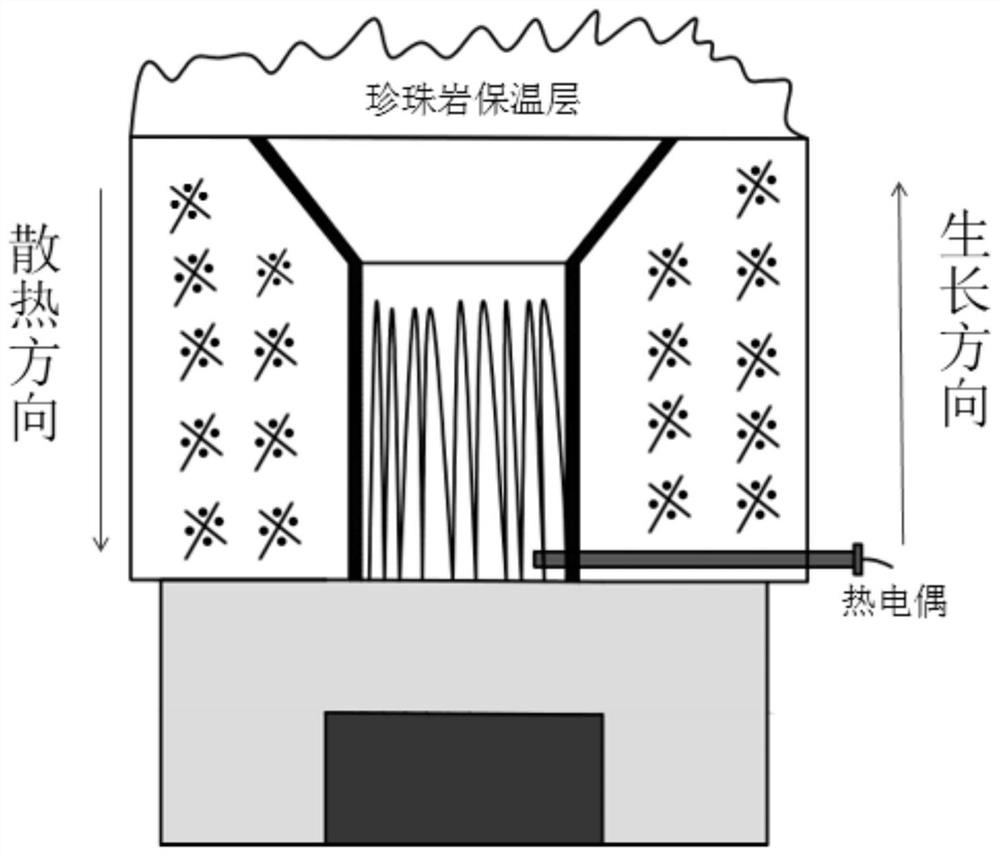

[0042] A method for preparing directionally solidified high-boron and high-vanadium high-speed steel, which is prepared by a directional solidification process, better controls the grain orientation of the solidified structure, and forms a continuous columnar grain structure. The specific steps are as follows:

[0043] S1. Add pig iron, scrap steel, low-carbon ferrochrome, ferromanganese, ferroboron, ferrovanadium, industrial pure iron, ferromolybdenum, ferrotungsten, and ferrosilicon as raw materials into the melting furnace for melting, and then add 0.148~ 0.152g of aluminum wire is deoxidized by furnace bottom deoxidation method, and the molten steel after scalding is returned to the furnace, and refined by blowing argon at the bottom for 8 to 15 minutes to obtain qualified, clean and impurity-free high-boron, high-vanadium high-speed steel molten steel for step S2;

[0044] The raw materials are pig iron, scrap steel, low-carbon ferrochrome, ferromanganese, ferroboron, ferr...

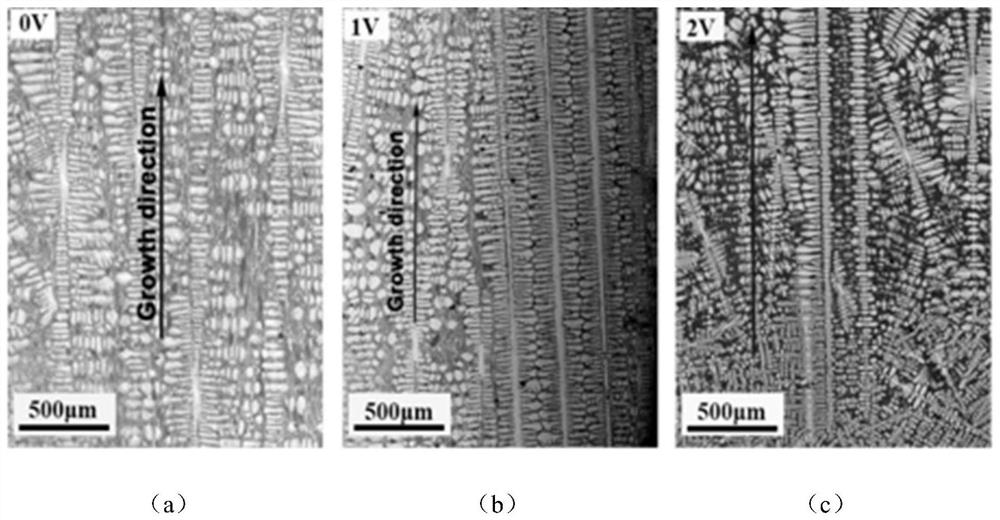

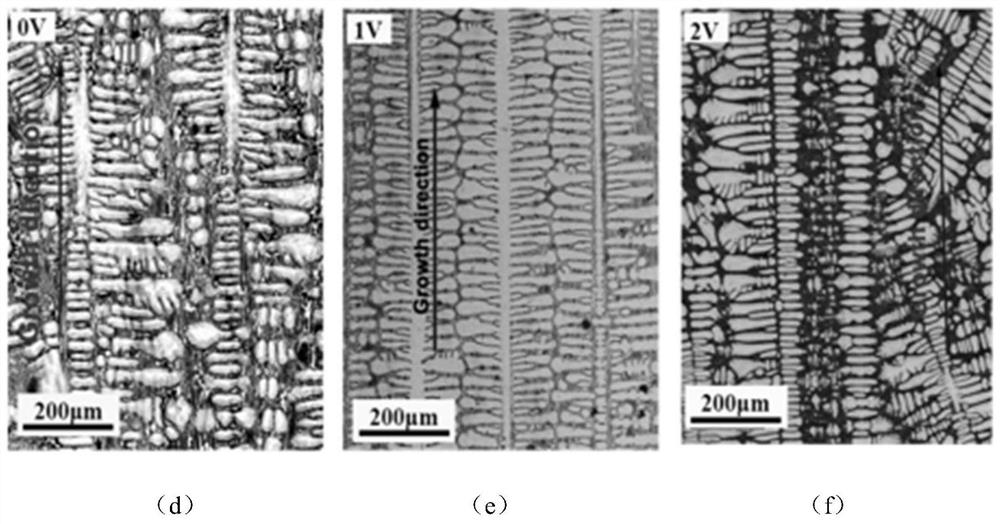

Embodiment 1

[0057] Directional Solidification Specimen Preparation

[0058]The invention selects pig iron, scrap steel, low-carbon ferrochrome, ferromanganese, ferroboron, ferrovanadium, industrial pure iron, ferromolybdenum, ferrotungsten, ferrosilicon and ferro-titanium as raw materials. Add 25.176% scrap steel (the chemical composition and mass fraction of scrap steel are 0.300% C, 0.300% Si, 0.500% Mn, and the balance is Fe), 41.852% pure iron (the chemical composition mass fraction of pure iron is 0.003% C, 0.020% Si, 0.150% Mn, the balance is Fe), 1.038% ferromanganese (the chemical composition mass fraction of ferromanganese is 6.410% C, 1.630% Si, 65.900% Mn, the balance is Fe), 0.463% ferrosilicon ( The chemical composition mass fraction of ferrosilicon is 0.100% C, 73.100% Si, the balance is Fe), 4.893% pig iron (the chemical composition mass fraction of pig iron is 4.270% C, 0.900% Si, 0.113% Mn, the balance is Fe) , 8.520% low-carbon ferrochromium (the chemical composition ma...

Embodiment 2

[0063] Directional Solidification Specimen Preparation

[0064] The invention selects pig iron, scrap steel, low-carbon ferrochrome, ferromanganese, ferroboron, ferrovanadium, industrial pure iron, ferromolybdenum, ferrotungsten, ferrosilicon and ferro-titanium as raw materials. Add 25.177% scrap steel (the chemical composition and mass fraction of scrap steel are 0.300% C, 0.300% Si, 0.500% Mn, and the balance is Fe), 41.852% pure iron (the chemical composition mass fraction of pure iron is 0.003% C, 0.020% Si, 0.150% Mn, the balance is Fe), 1.038% ferromanganese (the chemical composition mass fraction of ferromanganese is 6.410% C, 1.630% Si, 65.900% Mn, the balance is Fe), 0.463% ferrosilicon ( The chemical composition mass fraction of ferrosilicon is 0.100% C, 73.100% Si, the balance is Fe), 4.893% pig iron (the chemical composition mass fraction of pig iron is 4.270% C, 0.900% Si, 0.113% Mn, the balance is Fe) , 8.520% low-carbon ferrochromium (the chemical composition m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com